Exhaust gas in-cylinder direct injection turbulent combustion system and method

A technology of combustion system and exhaust gas cylinder, which is applied in the direction of charging system, exhaust gas recirculation, machine/engine, etc., can solve the problems of reducing intake air volume, potential risk of soot emission, and decrease of excess air coefficient, so as to prevent local The effect of over-rich mixture, promotion of fuel diffusion mixing, and suppression of NOx formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

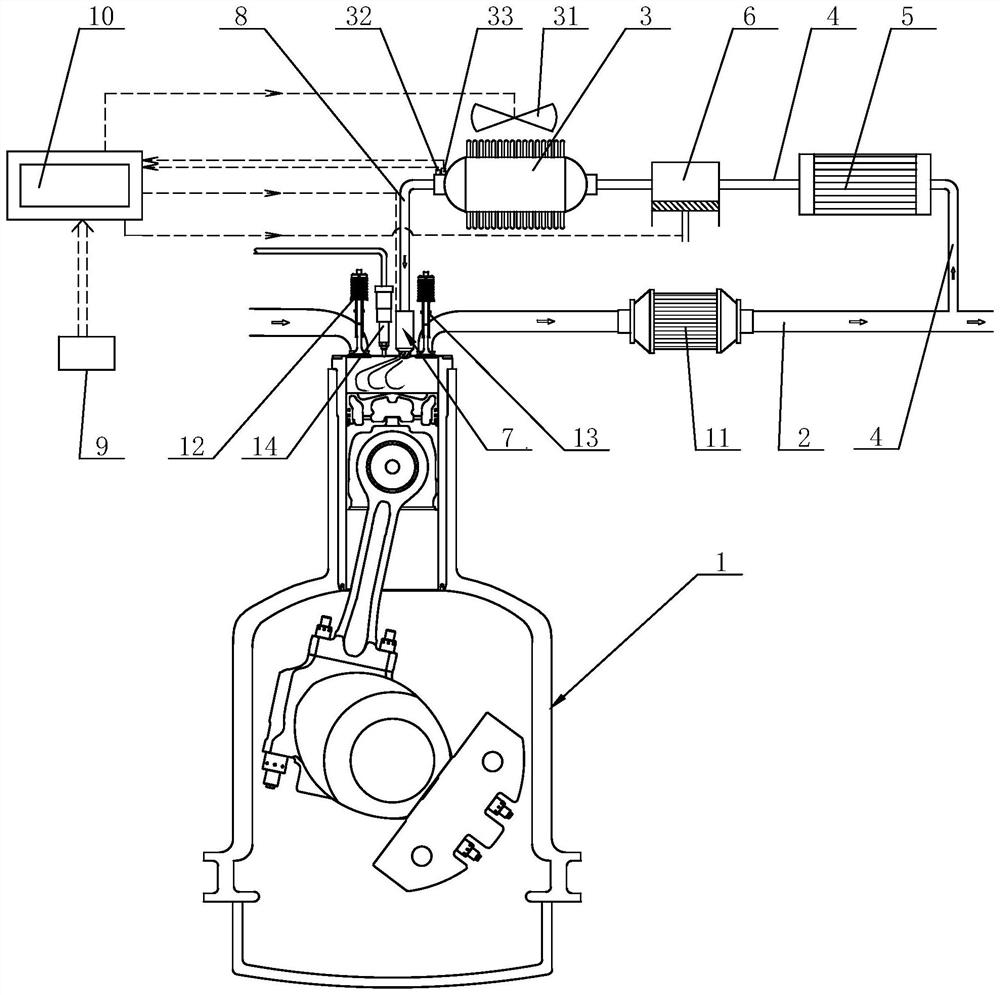

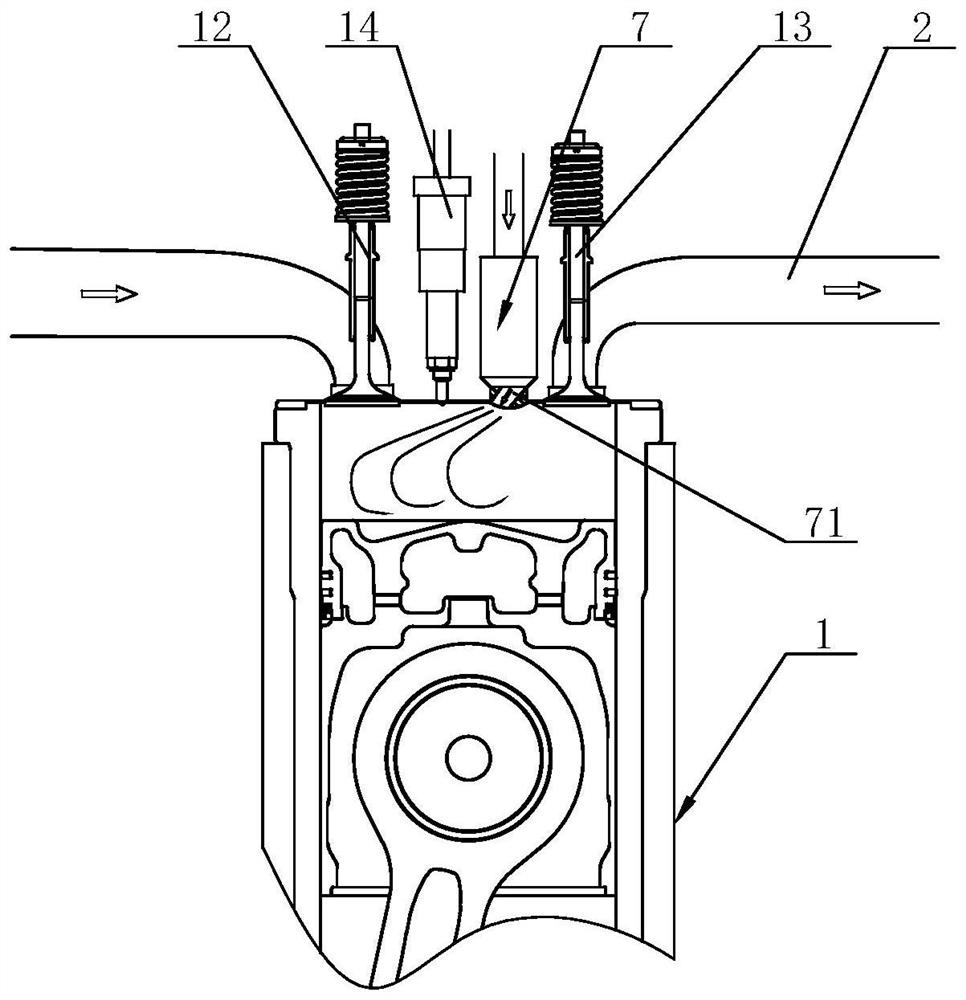

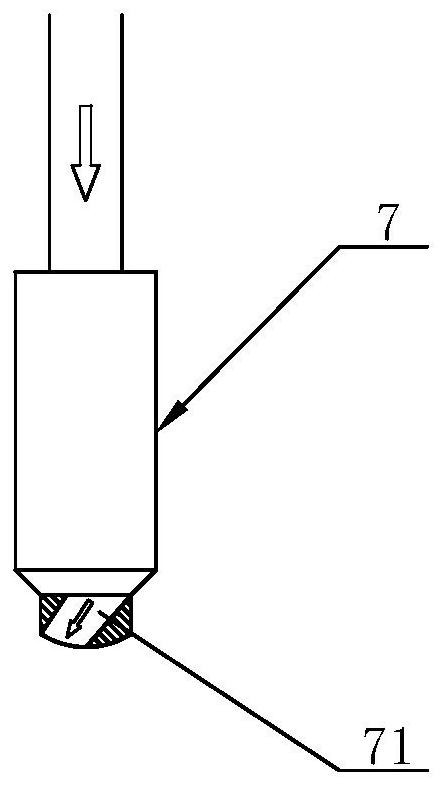

[0034] Such as figure 1 , figure 2 with image 3 Commonly shown, a waste gas in-cylinder direct injection turbulent combustion system includes a cylinder 1 and an exhaust pipe 2 communicating with the cylinder 1. The gas tank 3 communicates with the exhaust pipe 2 through the waste gas introduction pipe 4. The gas tank 3 is provided with Cooling system 31, the exhaust gas introduction pipe 4 is provided with an intercooler 5 and a compressor 6 in sequence along the exhaust gas flow direction; the exhaust gas injector 7 communicates with the gas tank 3 through the exhaust gas injection pipe 8, and the exhaust gas injector 7 is installed on the cylinder of the cylinder 1 Cover, the exhaust gas injector 7 injects exhaust gas into the cylinder 1 at a certain angle; the working condition detection unit 9 is used to detect the engine working condition, and output signals to the electronic control unit 10 (engine ECU); the electronic control unit 10 is used to detect the engine wor...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, the difference is that, as Figure 4 with Figure 5 Commonly shown, the outlet of the exhaust gas injector 7 is not provided with a guide channel 71, and the cylinder head of the cylinder 1 is provided with a guide channel 15 at the exhaust gas injector 7, and a guide channel 15 is provided between the guide channel 15 and the center line of the cylinder 1. There are angles.

[0049] To sum up, the waste gas in-cylinder direct injection turbulent combustion system and method provided by the embodiments of the present invention simultaneously reduce NOx and soot emissions without causing a decrease in engine power and economic performance; Optimal power, economy and emissions performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com