Ruthenium-palladium/carbon catalyst and preparation method thereof

A carbon catalyst and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as uneconomical production and high hydrogenation operating pressure, Achieve the effects of no three wastes discharge, improve surface properties, and increase oxygen-containing functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

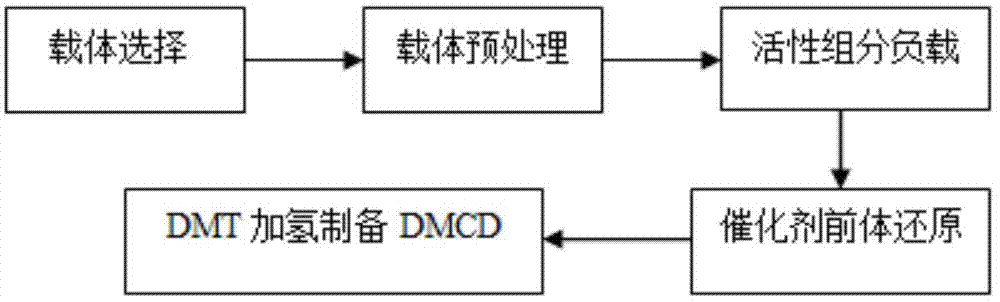

Method used

Image

Examples

Embodiment 1

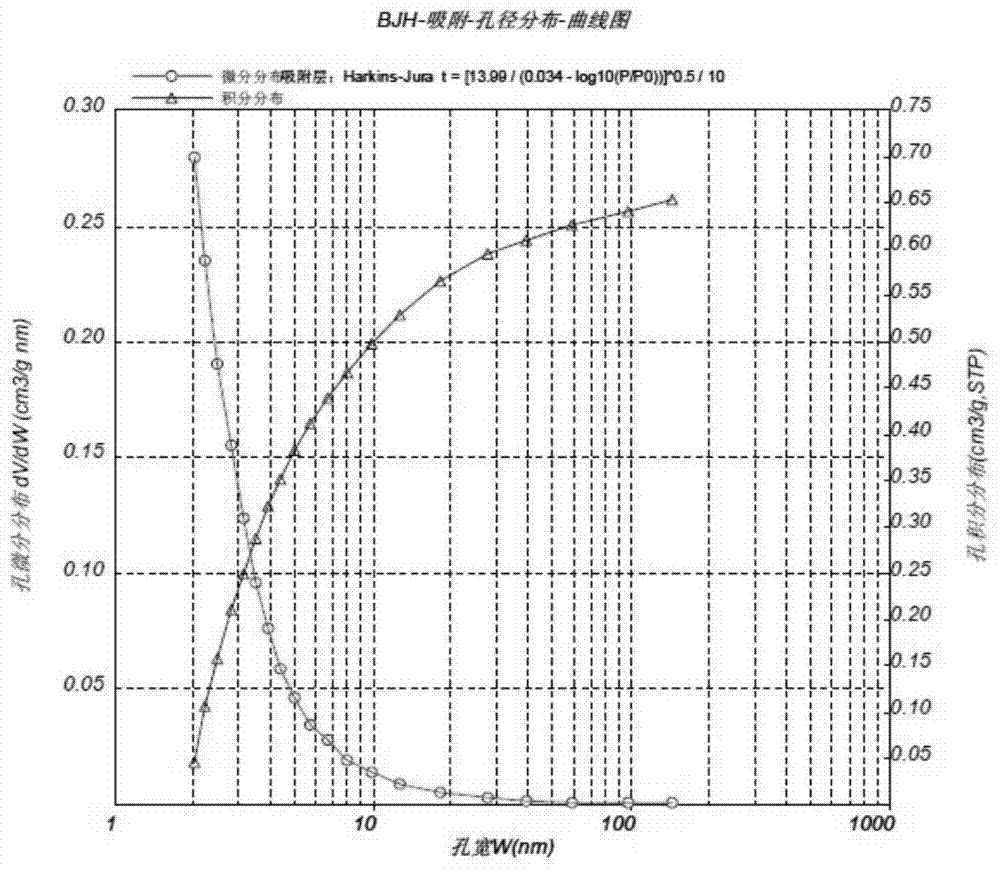

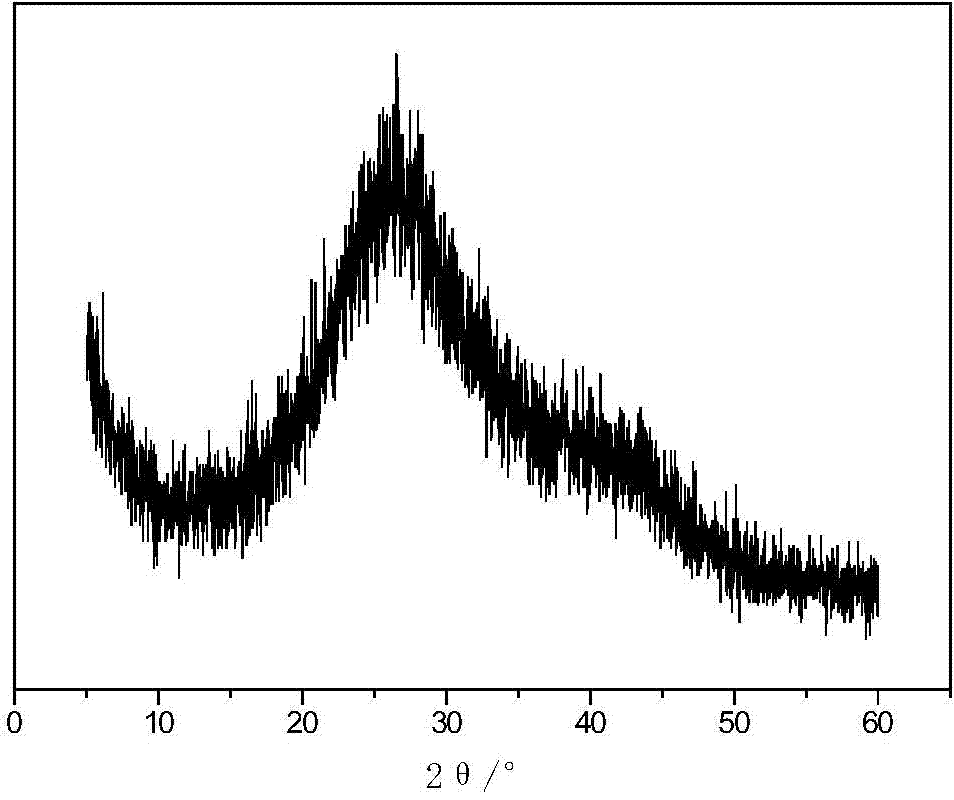

[0045] (1) Take 20g of self-made mesoporous carbon as the carrier material, place it in 80ml of 5mol / L nitric acid aqueous solution, immerse in a water bath at 80℃ for 12h, cool, filter, wash until neutral, and dry; at 120℃, vacuum conditions Lower degassing treatment for 2h;

[0046] (2) According to the active component ruthenium loading of 5.00% and palladium loading of 0.05%, respectively configure a 3mol / L ruthenium chloride solution and a 1.0mol / L palladium chloride solution;

[0047] (3) The acid-treated mesoporous carbon is impregnated with a ruthenium solution for 4 hours, dried at 80°C for 4 hours, and dried at 120°C for 6 hours by the vacuum equal amount impregnation method; the same method is used to impregnate the palladium solution, and then stand in a water bath at 80°C for 4 hours, at 80°C. Dry for 4 hours to obtain a ruthenium palladium-carbon catalyst precursor;

[0048] (4) Use a 10wt% NaOH aqueous solution to adjust the pH value to 11-12, precipitate for 2 hours,...

Embodiment 2

[0053] The ruthenium palladium / carbon catalysts with 8.0% and 1.0% ruthenium and palladium loadings were prepared by the same method as in Example 1. The catalyst number was CAT-2 / MC.

Embodiment 3

[0055] The ruthenium and palladium loadings were 3.0% and 0.1% ruthenium palladium / carbon catalysts prepared by the same method as in Example 1; the catalyst number was CAT-3 / MC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com