A preparation method of surface highly dispersed noble metal high index crystal plane nanoparticles

A high-index crystal face, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as low dispersion or utilization rate, difficult and unusable particles, etc. achieve good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

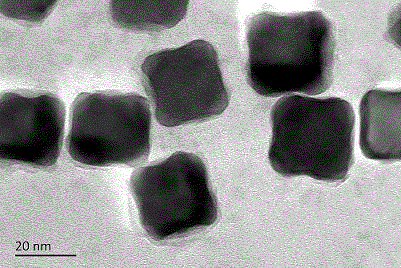

[0019] Embodiment 1: the surface layer is the synthesis of the concave surface (high index crystal surface) Ag nano cubic particle of Au crystal surface

[0020] 3 mL of aqueous dispersion containing 7 mg of Ag nanocubic particles was added to 20 mL of 2MKCl solution, followed by 600 mg of PVP and 10 mL of 0.5 mM HAuCl 4 solution, stirred at room temperature for 2 hours and kept it in the dark, after 30 hours, the sample was obtained, and the appearance was as follows: figure 1 TEM pictures show that HAuCl 4 After the introduction, the Ag nano-cubic particles change into Ag nano-cubic particles whose surface layer is Au crystal face (high-index crystal face).

Embodiment 2

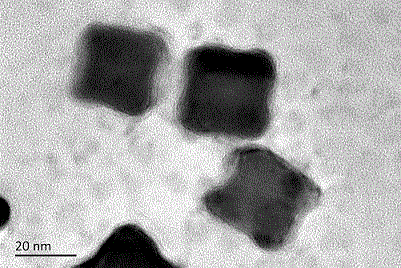

[0021] Embodiment two: the surface layer is the synthesis of the concave surface (high index crystal plane) Ag nano cubic particle of Pd crystal plane

[0022] 3 mL of aqueous dispersion containing 7 mg of Ag nanocubic particles was added to 20 mL of 2MKCl solution, followed by 600 mg of PVP and 10 mL of 0.5 mM Na 2 PdCl 4 Solution, after stirring at room temperature for 2 hours, it was left standing in the dark, and after 30 hours, the sample was obtained, and the appearance was as follows: figure 2 TEM photographs show that Na 2 PdCl 4 After the introduction, Ag nanocubic particles change into Ag nanocubic particles with concave surface (high index crystal plane) whose surface layer is Pd crystal plane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com