Production method of high-index crystal face constrained zinc oxide nano-ribbons

A zinc oxide nanometer and high-index crystal surface technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of strict atmosphere conditions, impure shape, and difficult control of hydrothermal process parameters, etc., to achieve The effect of low cost, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for high-index crystal plane confined zinc oxide nanoribbons, comprising the following steps:

[0037] (a) uniformly mixing zinc oxide and activated carbon powder according to a mass ratio of 1:1 to obtain raw material powder;

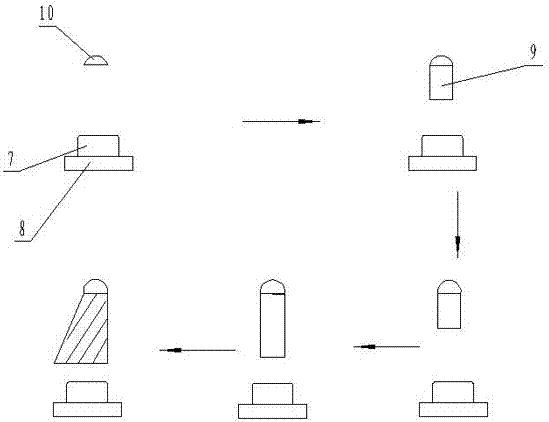

[0038] (b) Making the substrate: coating the surface of the silicon wafer with a layer of gold with a thickness of 10 nm as a catalyst to prepare a substrate as a growth substrate;

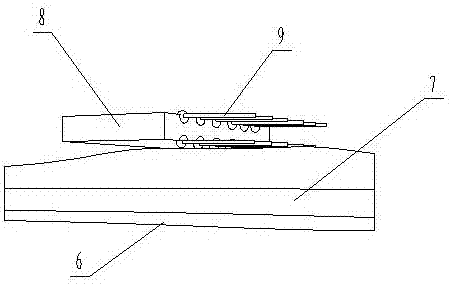

[0039] (c) Put the raw material powder processed in step (a) in the middle of the clay boat, and then buckle the substrate with the gold-plated side facing the direction of the raw material powder directly above the boat;

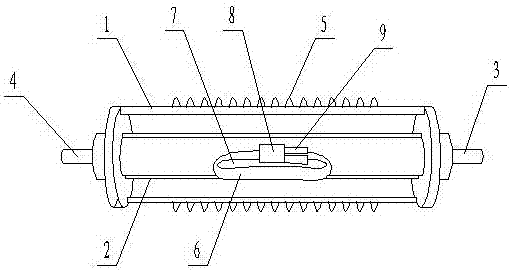

[0040] (d) Push the clay boat treated in step (c) smoothly to the high-temperature zone in the middle of the air-intake-solid reaction furnace, slightly biased towards the air-intake direction;

[0041] (e) Evacuate the vacuum in the gas-solid reaction furnace to below 231Torr;

[0042] (f) Gradually increase the temperatur...

Embodiment 2

[0045] A preparation method for high-index crystal plane confined zinc oxide nanoribbons, comprising the following steps:

[0046] (a) uniformly mixing zinc oxide and activated carbon powder according to a mass ratio of 1:1 to obtain raw material powder;

[0047] (b) Making the substrate: coating the surface of the silicon wafer with a layer of gold with a thickness of 12nm as a catalyst to prepare the substrate as the growth substrate;

[0048] (c) Put the raw material powder processed in step (a) in the middle of the clay boat, and then buckle the substrate with the gold-plated side facing the direction of the raw material powder directly above the boat;

[0049] (d) Push the clay boat treated in step (c) smoothly to the high-temperature zone in the middle of the air-intake-solid reaction furnace, slightly biased towards the air-intake direction;

[0050] (e) Pump the vacuum in the gas-solid reaction furnace below 300 Torr;

[0051] (f) Gradually increase the temperature i...

Embodiment 3

[0054] A preparation method for high-index crystal plane confined zinc oxide nanoribbons, comprising the following steps:

[0055] (a) uniformly mixing zinc oxide and activated carbon powder according to a mass ratio of 1:1 to obtain raw material powder;

[0056] (b) Making the substrate: coating the surface of the silicon wafer with a layer of gold with a thickness of 11 nm as a catalyst to prepare a substrate as a growth substrate;

[0057] (c) Put the raw material powder processed in step (a) in the middle of the clay boat, and then buckle the substrate with the gold-plated side facing the direction of the raw material powder directly above the boat;

[0058] (d) Push the clay boat treated in step (c) smoothly to the high-temperature zone in the middle of the air-intake-solid reaction furnace, slightly biased towards the air-intake direction;

[0059] (e) Evacuate the vacuum in the gas-solid reaction furnace to below 231Torr;

[0060] (f) Gradually increase the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com