Method for preparing micro-fine spherical Mn3O4 powder by using MnCO3 as raw material

A powder and fine technology, applied in the direction of manganese oxide/manganese hydroxide, etc., to achieve the effect of fine particle size, high sphericity, and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Fine spherical Mn with an average particle size of 5 μm 3 o 4 Powder preparation:

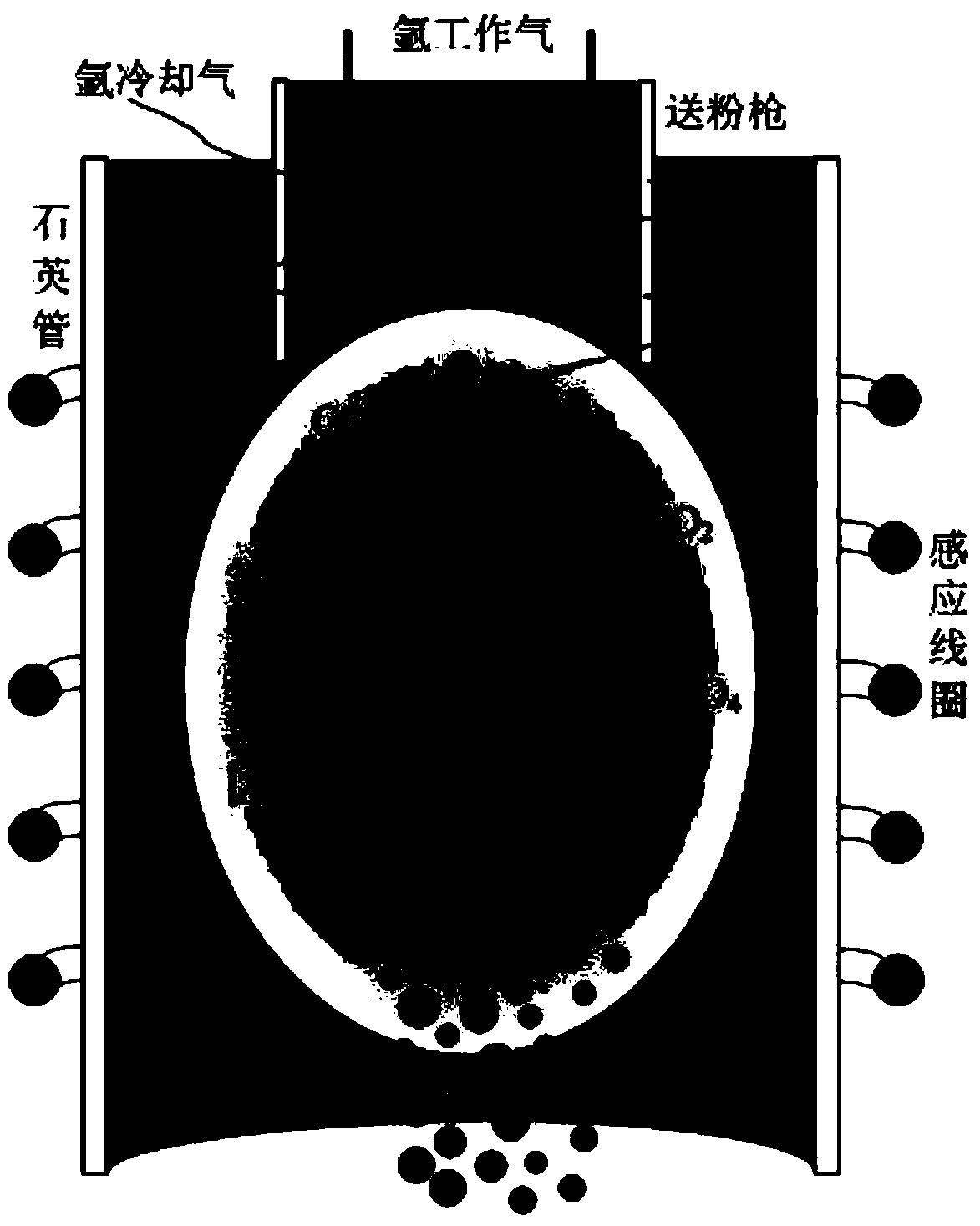

[0026] Relying on inductively coupled plasma technology to establish a stable Ar-O 2 Inductively coupled plasma power is 60KW, plasma working gas (Ar) flow is 35slpm, side gas flow is 200slpm (Ar)r+20slpm (O 2 ), MnCO with an average particle size of 50 μm was mixed with argon at a flow rate of 5 slpm 3 The powder is axially fed into the high temperature plasma, the powder feeding rate is 15g / min, MnCO 3 After the particles go through a series of processes of thermal decomposition, crushing, melting spheroidization and condensation into spheres in the plasma high temperature area, they can receive fine spherical Mn particles with an average particle size of 5 μm. 3 o 4 pink.

Embodiment 2

[0028] Fine spherical Mn with an average particle size of 15 μm 3 o 4 Powder preparation:

[0029] Relying on inductively coupled plasma technology to establish a stable Ar-O 2 The inductively coupled plasma power is 60KW, the plasma working gas (Ar) flow rate is 45slpm, and the edge gas flow rate is 250slpm (Ar)r+25slpm (O 2 ), MnCO with an average particle size of 100 μm 3 The powder is axially fed into the high temperature plasma, the powder feeding rate is 20g / min, MnCO 3 After the particles go through a series of processes of thermal decomposition, crushing, melting spheroidization and condensation into spheres in the plasma high temperature area, they can receive fine spherical Mn particles with an average particle size of 15 μm. 3 o 4 pink.

Embodiment 3

[0031] Fine spherical Mn with an average particle size of 20 μm 3 o 4 Powder preparation:

[0032] Relying on inductively coupled plasma technology to establish a stable Ar-O 2 The inductively coupled plasma power is 60KW, the plasma working gas (Ar) flow rate is 50slpm, and the edge gas flow rate is 260slpm (Ar)r+26slpm (O 2 ), MnCO with an average particle size of 150 μm 3 The powder is axially fed into the high temperature plasma, the powder feeding rate is 35g / min, MnCO 3 After the particles go through a series of processes of thermal decomposition, crushing, melting spheroidization and condensation into spheres in the plasma high temperature area, they can receive fine spherical Mn particles with an average particle size of 20 μm. 3 o 4 pink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com