Water purification machine

A pure water machine and pure water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of high production labor costs and after-sales maintenance costs The water quality is not fresh, the internal space of the machine is large, etc., to reduce the risk of water leakage, avoid the effect of stale water quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

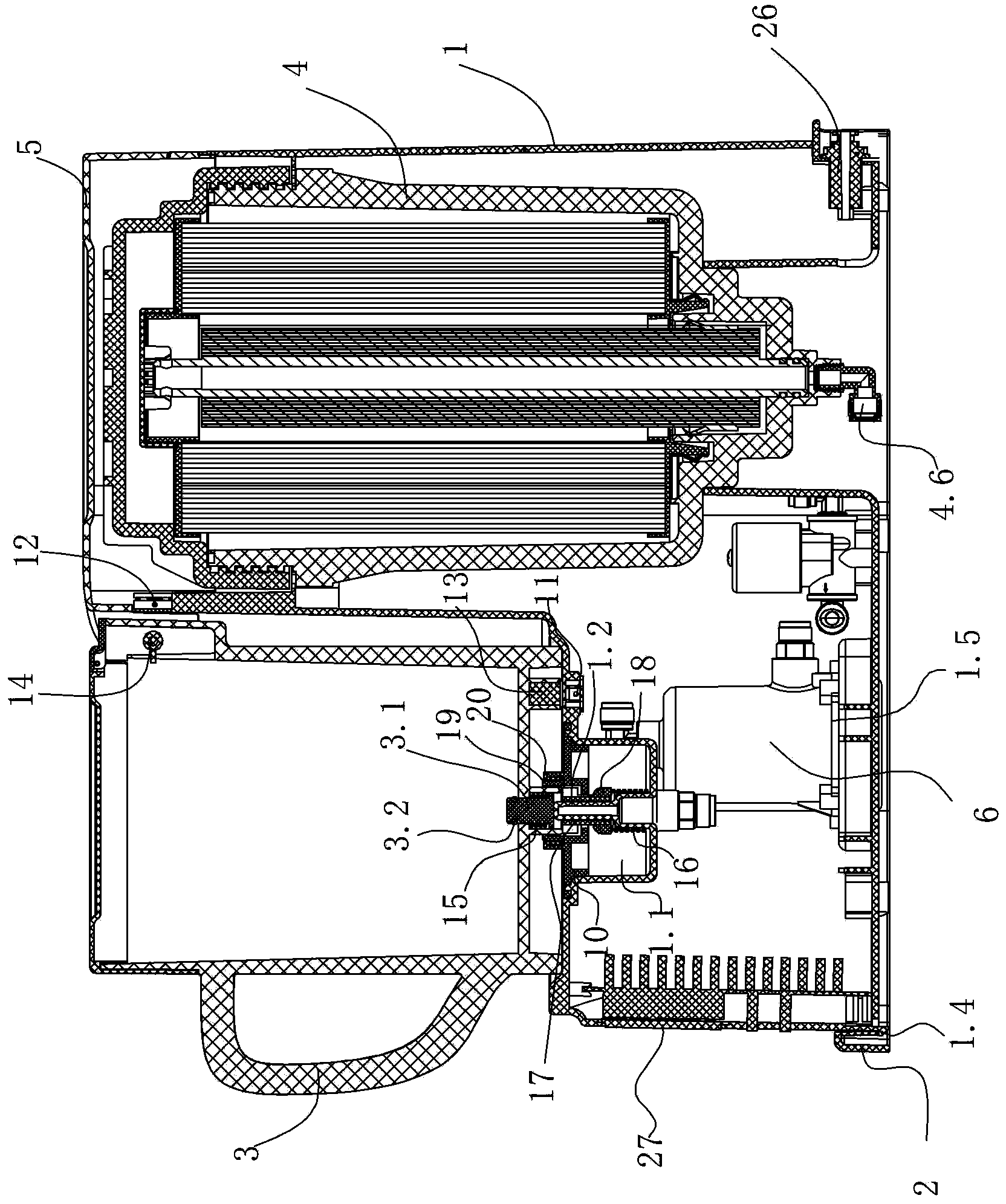

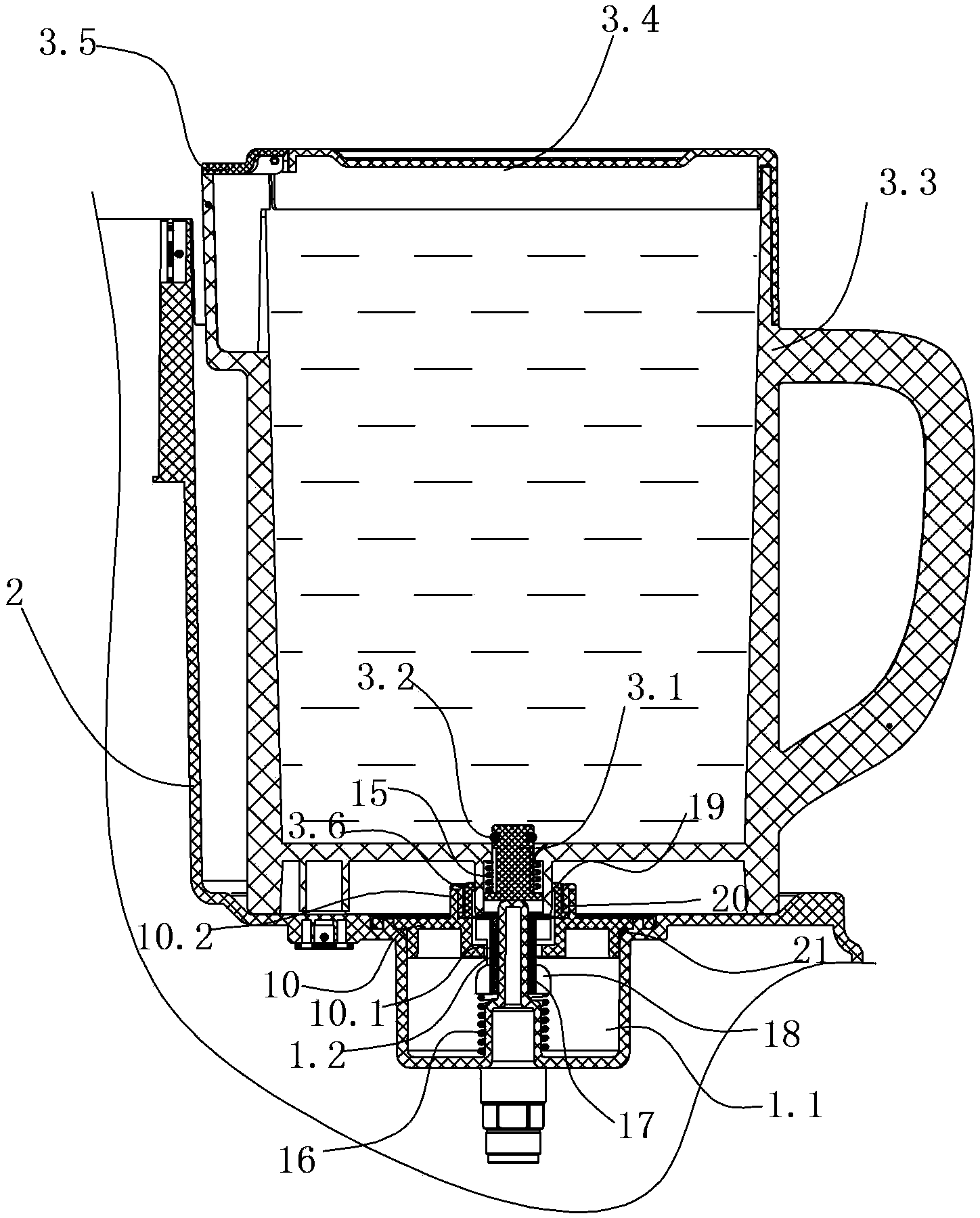

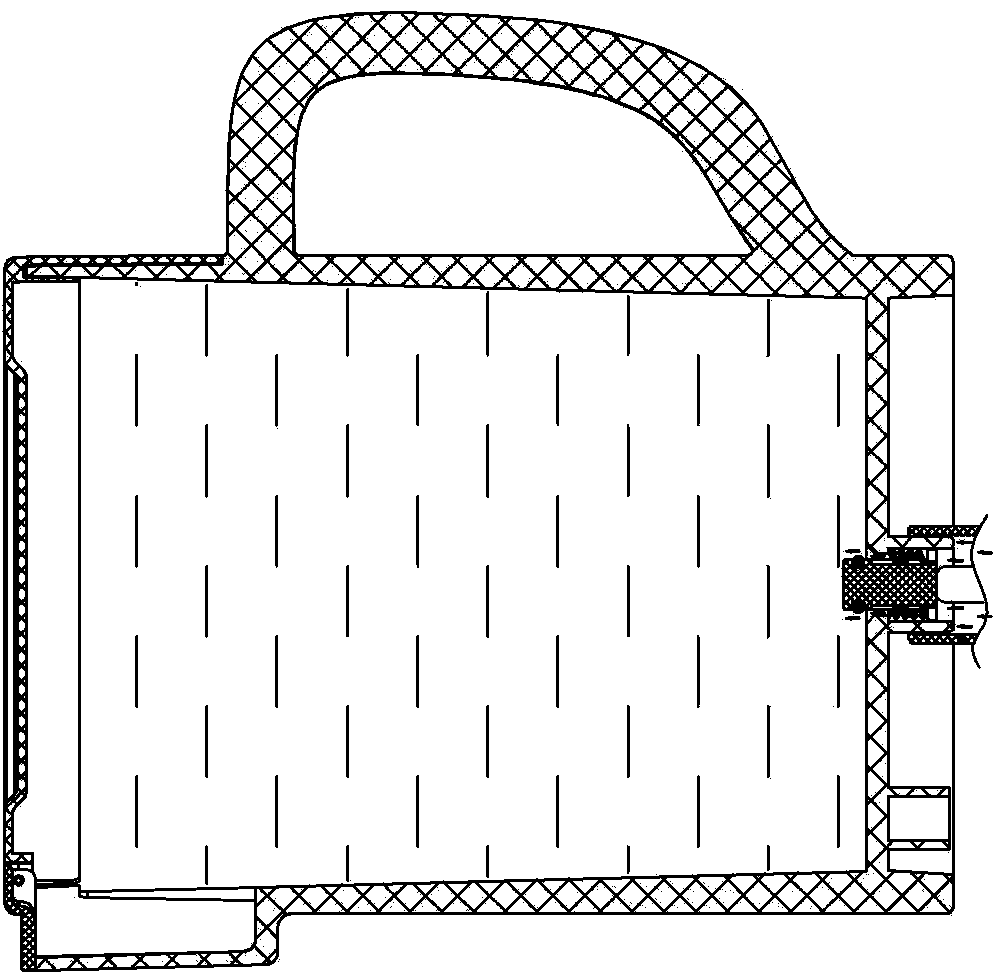

[0024]As shown in the figure, a pure water machine includes a shell formed by combining a body 1 and a base 2, a water cup assembly 3 located on the body 1, and a composite filtration system including an RO membrane module installed on the base 2, Booster water pump 9, water inlet solenoid valve 7, waste water solenoid valve 8, low pressure switch 22 and other components, filtration system including RO membrane module, booster water pump 9, water inlet solenoid valve 7, waste water solenoid valve 8, low pressure switch 22 and other components are connected to form a pure water system. The water cup assembly 3 includes a cup body 3.3, a cup cover 3.4, a spout 3.5 and a self-closing valve 3.1. The lower end of the cup body 3.3 has a water inlet, and the outside of the water inlet is provided with a water inlet column 3.6 , the self-closing valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com