Spinning type micro-vortex flocculation device

A spin-type micro and flocculation device technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of discount of flocculation effect, and achieve the effects of enhanced adaptability, stable operation and remarkable flocculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

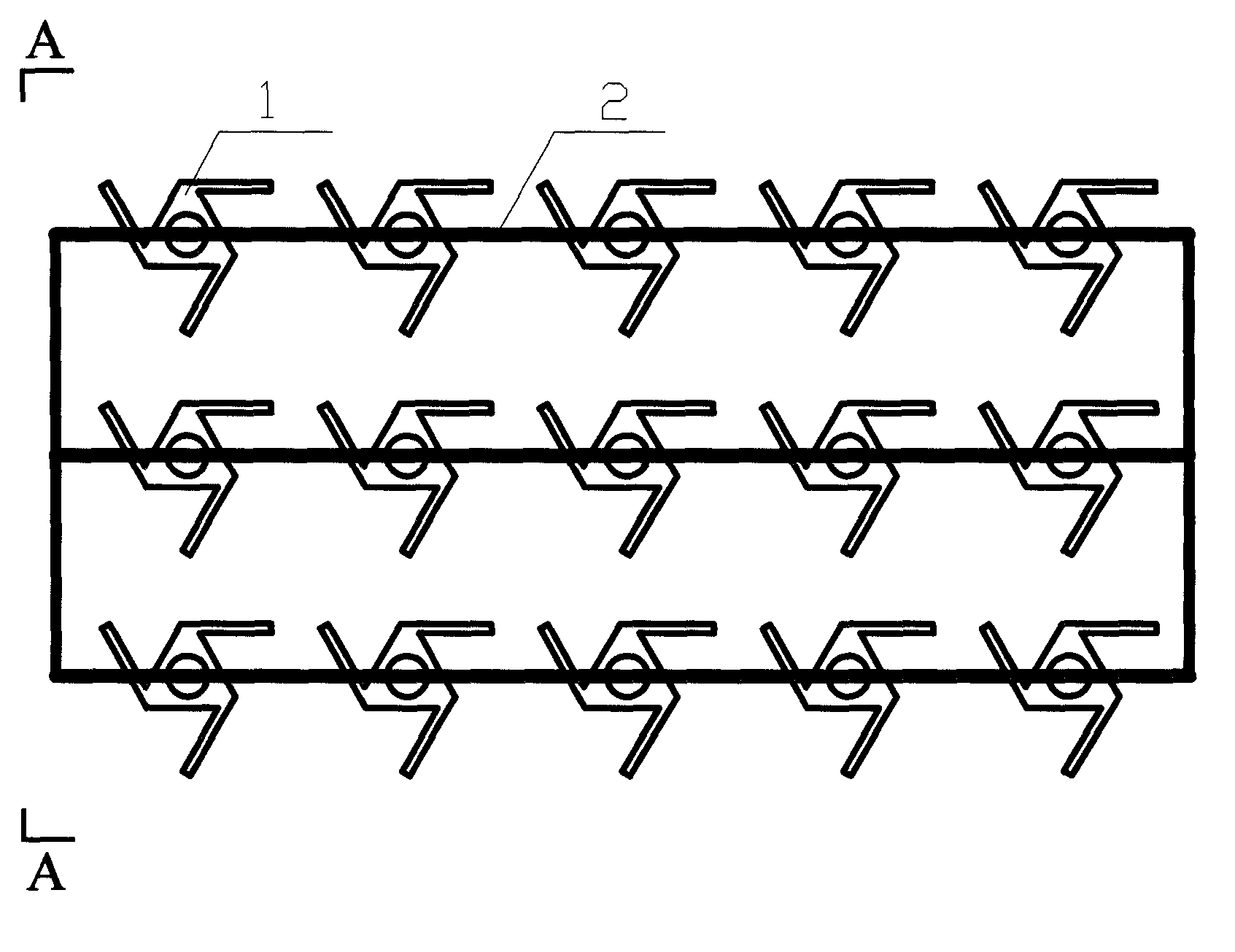

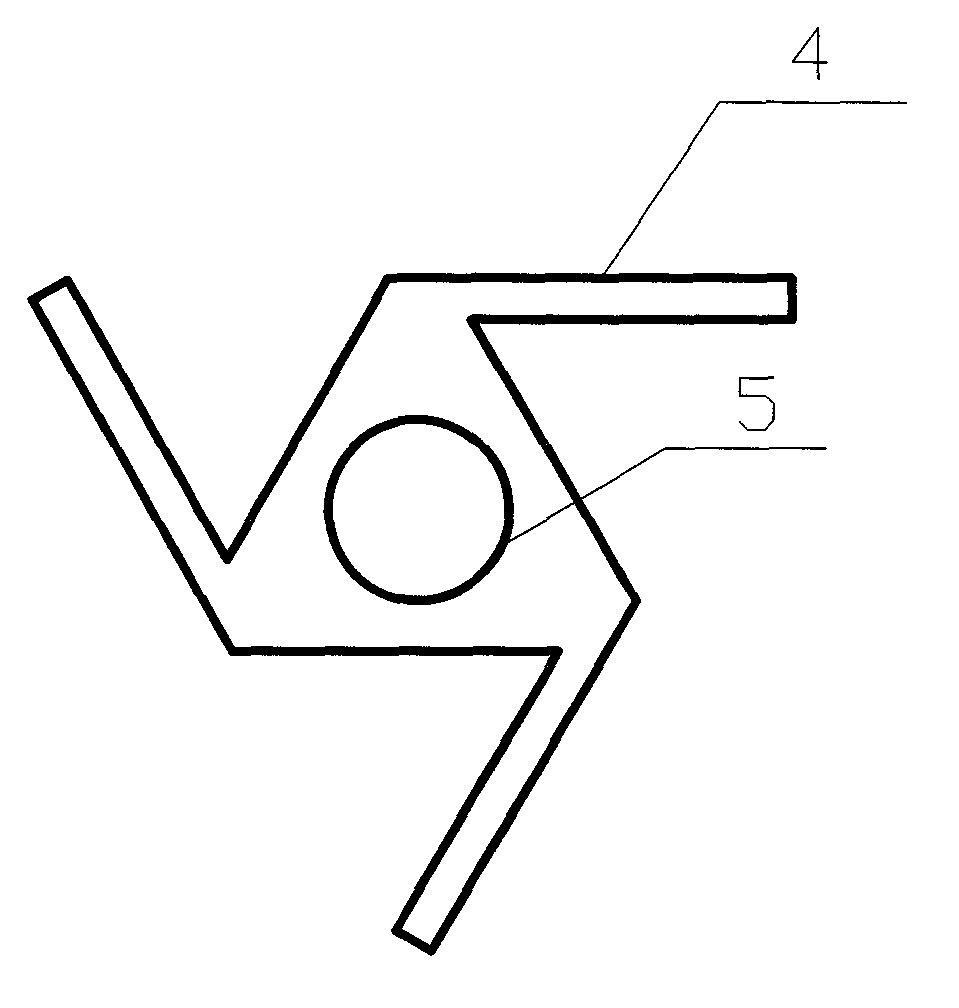

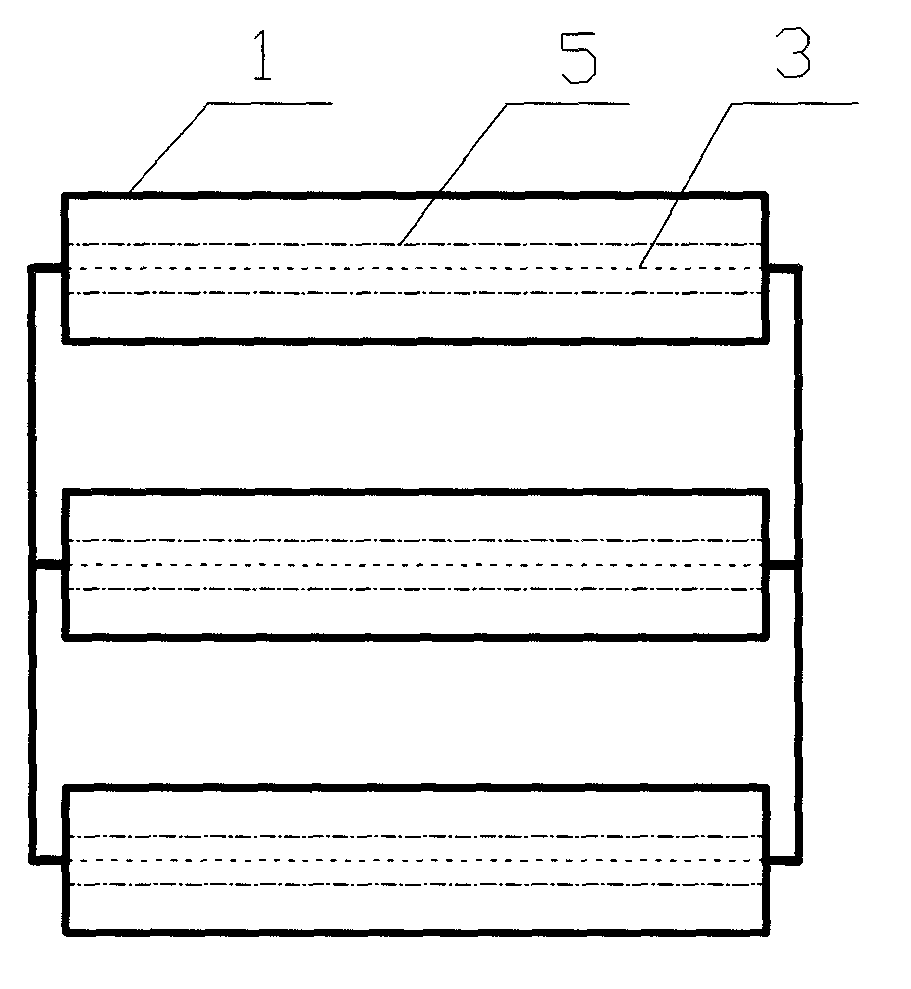

[0025] Such as figure 1 As shown, the spin-type micro-vortex flocculation device is composed of a flocculation ring 1 , a support frame 2 , a connecting rod 3 and other components, and the flocculation ring 1 includes blades 4 and circular openings 5 . The whole flocculation ring 1 is made of modified polypropylene material and formed by injection molding process. The manufacturing process uses a mechanical injection mold for one-time molding. During assembly, the flocculation ring 1 is first passed through the connecting rod 3 and then fixed to the support frame 2 . Both the support frame 2 and the connecting rod 3 are made of stainless steel. During assembly, between the support frame 2 and the support frame 2, between the support frame 2 and the connecting rod 3 are welded or fixed in other ways.

[0026] The structure of the spin micro-vortex flocculation device is arranged in layers, with at least 3 layers, each layer is equipped with at least 4 flocculation rings, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com