Method for preparing propylene by fluidized bed olefin disproportionation

A technology for olefin disproportionation and fluidized bed catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Collapse, good technical effect, delayed poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

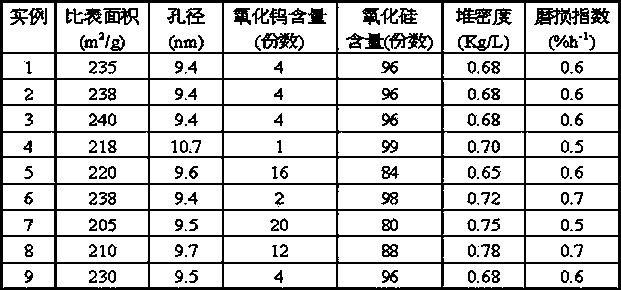

[0023] Soak 1 kg of silicon oxide in 2 kg of deionized water for 10 minutes, beat for 10 minutes, add 200 grams of ammonium metatungstate solution containing 63 grams, and finally add 200 grams of silica sol (40% silicon oxide content) for 15 minutes of beating to obtain 40 % solid content of slurry. The slurry was spray-dried at an inlet air temperature of 600°C and an outlet air temperature of 350°C, and then baked in a muffle furnace at 600°C for 4 hours to make a catalyst. The average particle size of the catalyst was 60 microns. The bulk density and Wear index, results list 1.

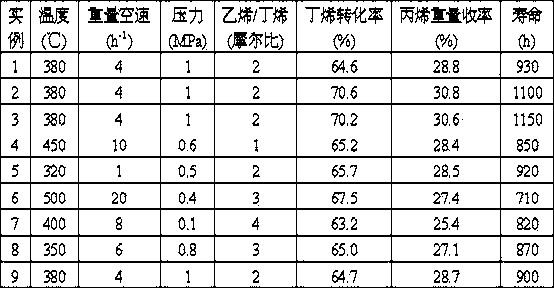

[0024] Install 30 grams of catalyst in a Φ30 fluidized bed reactor, and evaluate the conditions and results in Table 2.

[0025]

Embodiment 2

[0027] Soak 1 kilogram of silicon oxide in 2 kilograms of deionized water for 10 minutes, beat for 10 minutes, add 200 grams of a solution containing 63 grams of ammonium metatungstate, 30 grams of lanthanum nitrate, and 31 grams of zirconium nitrate, and finally add 200 grams of silica sol (oxidized Silicon content 40%) beating for 15 minutes to obtain a slurry with 40% solid content. The slurry was spray-dried at an inlet air temperature of 600°C and an outlet air temperature of 350°C, and then baked in a muffle furnace at 600°C for 4 hours to make a catalyst. The average particle size of the catalyst was 60 microns. The bulk density and Wear index, results list 1.

[0028] Install 30 grams of catalyst in a Φ30 fluidized bed reactor, and evaluate the conditions and results in Table 2.

[0029]

Embodiment 3

[0031] Soak 1 kilogram of silicon oxide in 2 kilograms of deionized water for 10 minutes, beat for 10 minutes, add 200 grams of a solution containing 63 grams of ammonium metatungstate, 60 grams of lanthanum nitrate, and 93 grams of zirconium nitrate, and finally add 200 grams of silica sol (oxidized Silicon content 40%) beating for 15 minutes to obtain a slurry with 40% solid content. The slurry was spray-dried at an inlet air temperature of 600°C and an outlet air temperature of 350°C, and then baked in a muffle furnace at 600°C for 4 hours to make a catalyst. The average particle size of the catalyst was 60 microns. The bulk density and Wear index, results list 1.

[0032] Install 30 grams of catalyst in a Φ30 fluidized bed reactor, and evaluate the conditions and results in Table 2.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com