Controllable preparation method of carbazole bromo-compound

A compound, the technology of carbazole bromide, which is applied in the field of controllable preparation of carbazole bromide compounds, achieves the effects of high yield, mild reaction conditions and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

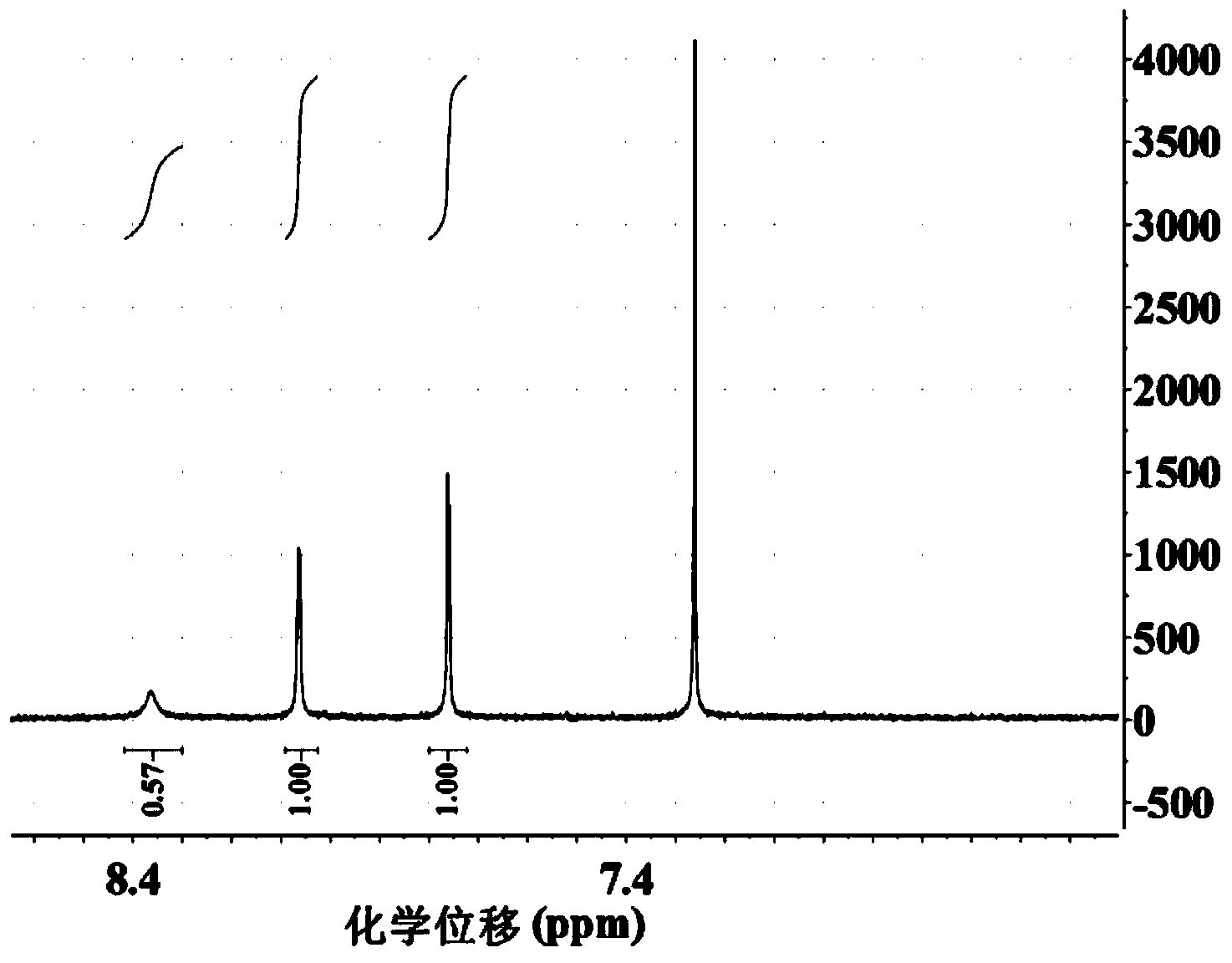

[0030] Using carbazole as the starting material, react with N-bromosuccinimide to synthesize 1,3,6,8-tetrabromocarbazole compound:

[0031]

[0032] Reaction Scheme

[0033]

[0034] Step 1: Under a nitrogen atmosphere, add 5 g (29.94 mmol) of carbazole and 15 mL of N,N-diformamide to a three-necked flask equipped with magnetic stirring. After the carbazole is completely dissolved, the prepared concentration is 1.996 mol / For solution A of L, reduce the reaction system to 5°C with an ice-water bath; N-bromosuccinimide (21.317 g, 119.76 mmol) was dissolved in 100 mL N,N-diformamide to prepare a concentration of 1.1976 mol / L solution B, the ratio of the amount of N,N-diformamide in solution B to the amount of N,N-diformamide in solution A is 20:3;

[0035] Step 2: Control the reaction temperature at 5°C, slowly add solution B to solution A slowly with a constant pressure funnel;

[0036] Step 3: After the dropwise addition, react at room temperature for 10 hours;

[00...

Embodiment 2

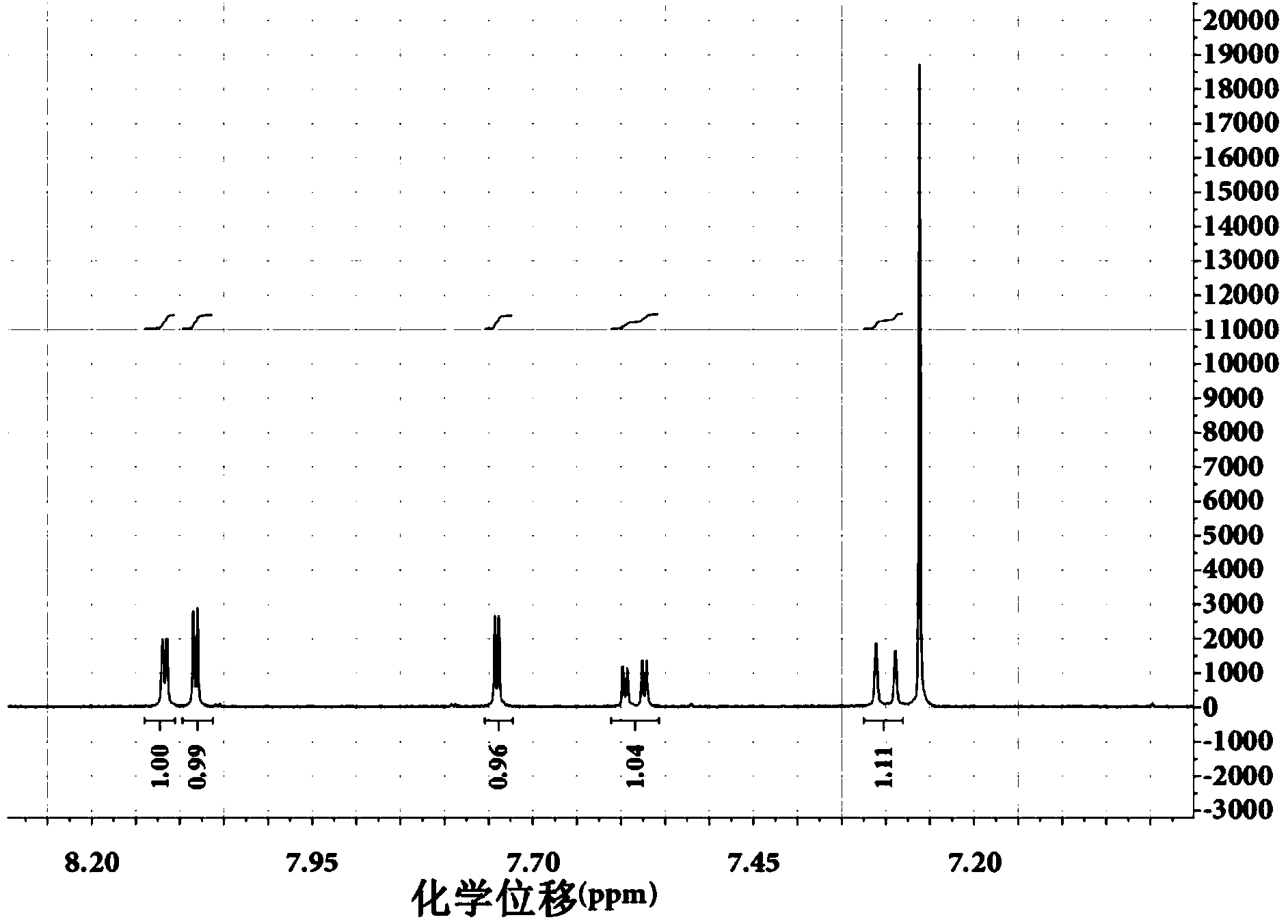

[0040] Using carbazole as the starting material, react with N-bromosuccinimide to synthesize 1,3,6-tribromocarbazole:

[0041]

[0042] Reaction Scheme

[0043]

[0044] Step 1: Under a nitrogen atmosphere, add 5 g (29.94 mmol) of carbazole and 15 mL of N,N-diformamide to a three-necked flask equipped with magnetic stirring. After the carbazole is completely dissolved, the prepared concentration is 1.996 mol / For solution A of L, the reaction system was lowered to 3°C with an ice-water bath; N-bromosuccinimide (15.898 g, 89.82 mmol) was dissolved in 100 mL N,N-diformamide to prepare a concentration of 0.8932 mol / L solution B, the ratio of the amount of N,N-diformamide in solution B to the amount of N,N-diformamide in solution A is 20:3;

[0045] Step 2: Control the reaction temperature at 3°C, and slowly add solution B to solution A dropwise with a constant pressure funnel;

[0046] Step 3: After the dropwise addition, react at room temperature for 10 hours;

[0047] S...

Embodiment 3

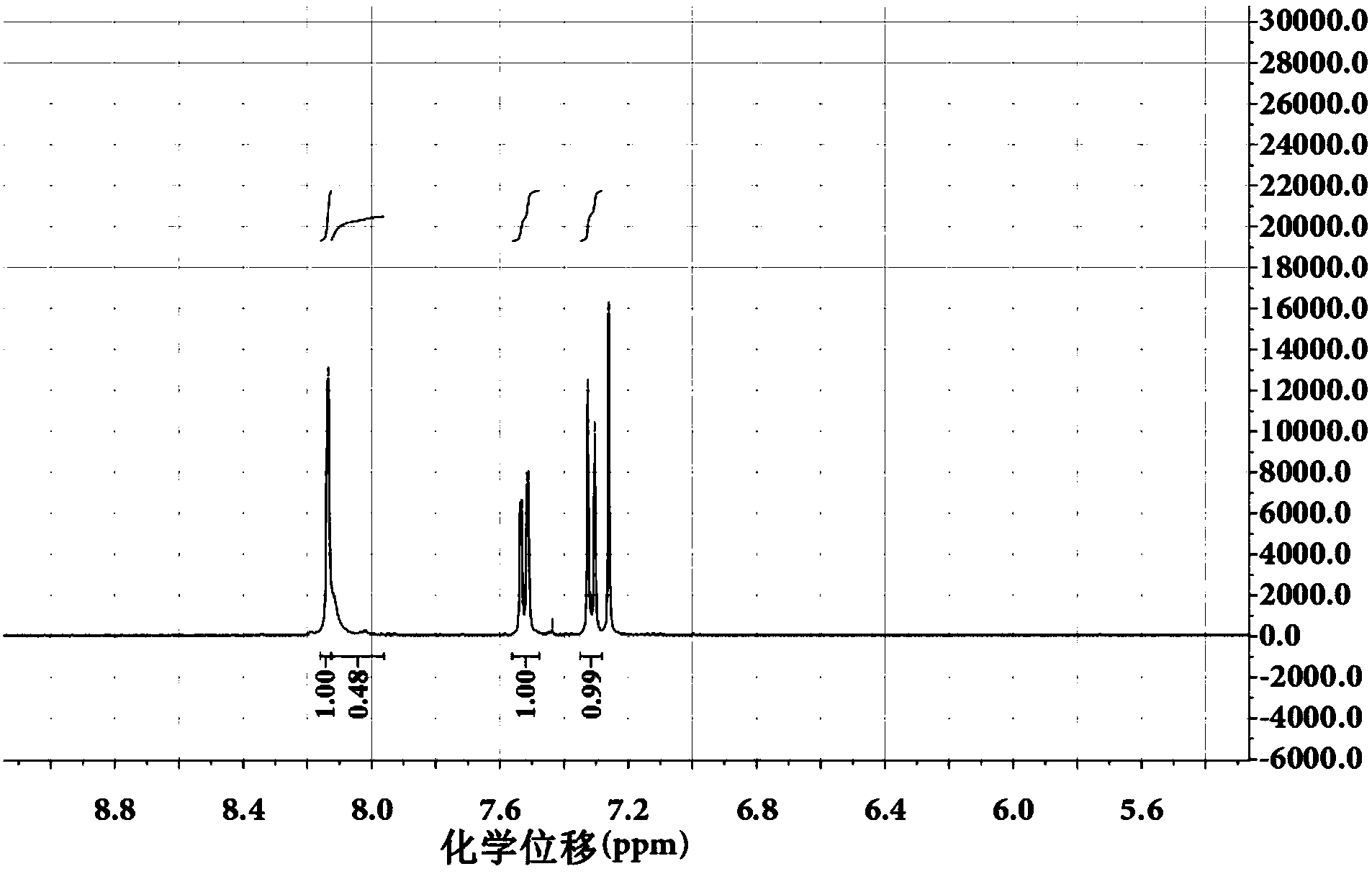

[0051] Using carbazole as the starting material, react with N-bromosuccinimide to synthesize 3,6-dibromocarbazole:

[0052]

[0053] Scheme of the reaction scheme:

[0054]

[0055] Step 1: Under a nitrogen atmosphere, add 5 g (29.94 mmol) of carbazole and 15 mL of N,N-diformamide to a three-necked flask equipped with magnetic stirring. After the carbazole is completely dissolved, the prepared concentration is 1.996 mol / For solution A of L, reduce the reaction system to 0°C with an ice-water bath; N-bromosuccinimide (10.601 g, 59.84 mmol) was dissolved in 60 mL N,N-diformamide to prepare a concentration of 0.9973 mol / L solution B, the ratio of the amount of N,N-diformamide in solution B to the amount of N,N-diformamide in solution A is 4:1;

[0056] Step 2: Control the reaction temperature at 0°C, and slowly add solution B to solution A slowly with a constant pressure funnel;

[0057] Step 3: After the dropwise addition, react at room temperature for 10 hours;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com