A kind of extraction method of taro starch

A technology of taro starch and extraction method, which is applied in the field of food processing, can solve the problems of poor quality, low purity and low extraction rate, and achieve the effect of high safety and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

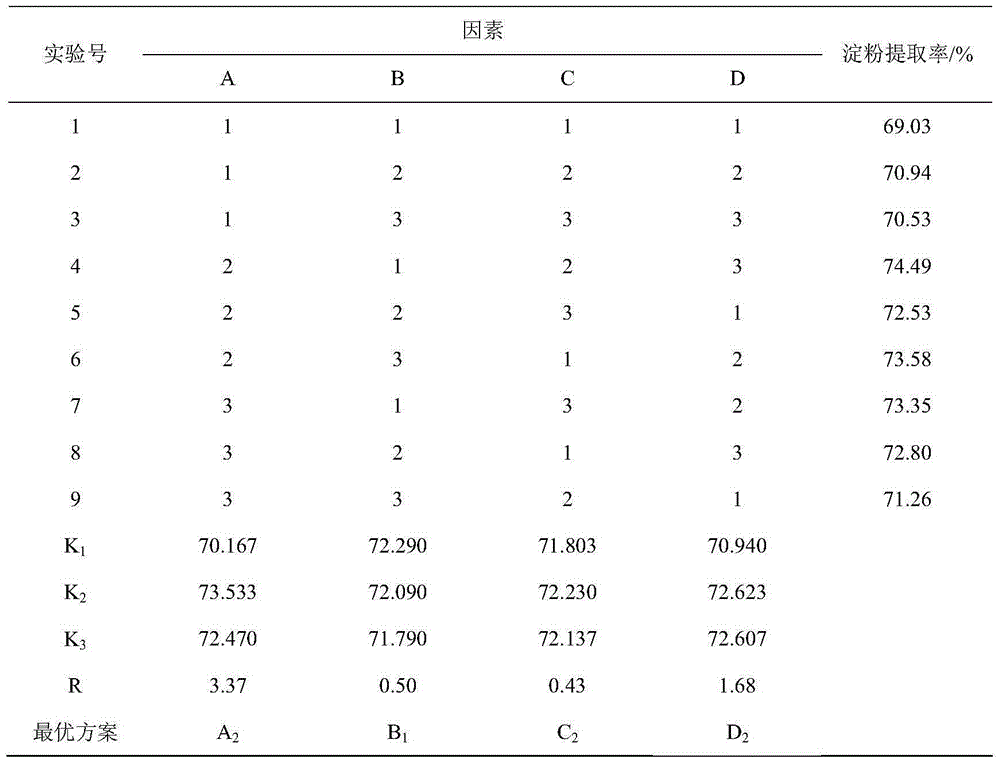

[0021] Single enzyme experiment - xylanase enzymatically hydrolyzes taro to extract starch, and the amount of xylanase added is 15g.

[0022] Get 1 kg of taro slices after cleaning and peeling, and 500 mL of phosphate buffer (the unit of w in the mass-volume ratio w / v of taro slices and phosphate buffer solution w / v in the present invention is g, and the unit of corresponding volume v is mL), put Homogenize in a plant tissue masher, use ultrasonic treatment (400W, 20min); add xylanase for enzymolysis; maintain temperature at 50°C; pH value 5.0; enzymolysis time 5h; inactivate enzyme, 3000r / min Centrifuge for 20 min for separation and purification, discard the supernatant, and dry in an oven.

[0023] It was determined that the extraction rate of starch was 72%, and the purity was 75%. The addition of xylanase degrades xylan and destroys the cell wall of taro tissue, which is beneficial to the dissolution of starch. But at this time, some starch granules are still combined wi...

Embodiment 2

[0025] Single enzyme experiment—neutral protease enzymatically hydrolyzes taro to extract starch, and the amount of neutral protease added is 15g.

[0026] Take 1kg of washed and peeled taro slices, 500mL of phosphate buffer, put them in a plant tissue masher for homogenization, and use ultrasonic treatment (400W, 20min); add neutral protease for enzymatic hydrolysis; maintain the temperature at 50°C; The pH value is 7.0; the enzymatic hydrolysis time is 5 hours; inactivate the enzyme, centrifuge at 3000r / min for 20 minutes to separate and purify, discard the supernatant, and dry in an oven.

[0027] It was determined that the extraction rate of starch was 73%, and the purity was 75%. When neutral protease was added alone, the cell wall structure was not destroyed, and the tightly arranged structure hindered the enzymatic hydrolysis of protease and starch cross-linked protein, and hindered the extraction of taro starch.

[0028] Therefore, the present invention considers adop...

Embodiment 3

[0030] Compounding experiment——simultaneously adding xylanase and neutral protease to hydrolyze taro to extract starch, the amount of xylanase added is 12g, and the amount of neutral protease added is 3g.

[0031] Take 1kg of washed and peeled taro slices, 500mL of phosphate buffer, put them in a plant tissue masher for homogenization, and use ultrasonic treatment (400W, 20min); at the same time, add xylanase and neutral protease for enzymatic hydrolysis; The temperature was maintained at 50°C; the pH value was 6.0; the enzymatic hydrolysis time was 5 hours; the enzyme was inactivated and centrifuged at 3000r / min for 20min for separation and purification, the supernatant was discarded and dried in an oven.

[0032] After determination, the starch extraction rate was 74%, and the purity was 75%.

[0033] The optimum pH range of xylanase is 4.5-6.5, and the optimum pH range of neutral protease is 6.5-7.5. The simultaneous enzyme addition method sets the pH at 6.0, which is not c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com