Preparation method of propylene-alpha-olefin random copolymer

A technology of random copolymer and propylene, which is applied in the field of propylene random copolymer and its preparation and application, can solve the problems of low heat sealing performance, increased deposits, and decreased high temperature resistance, and achieves good film-forming processing performance, and can be The effect of low content of dissolved substances and good heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

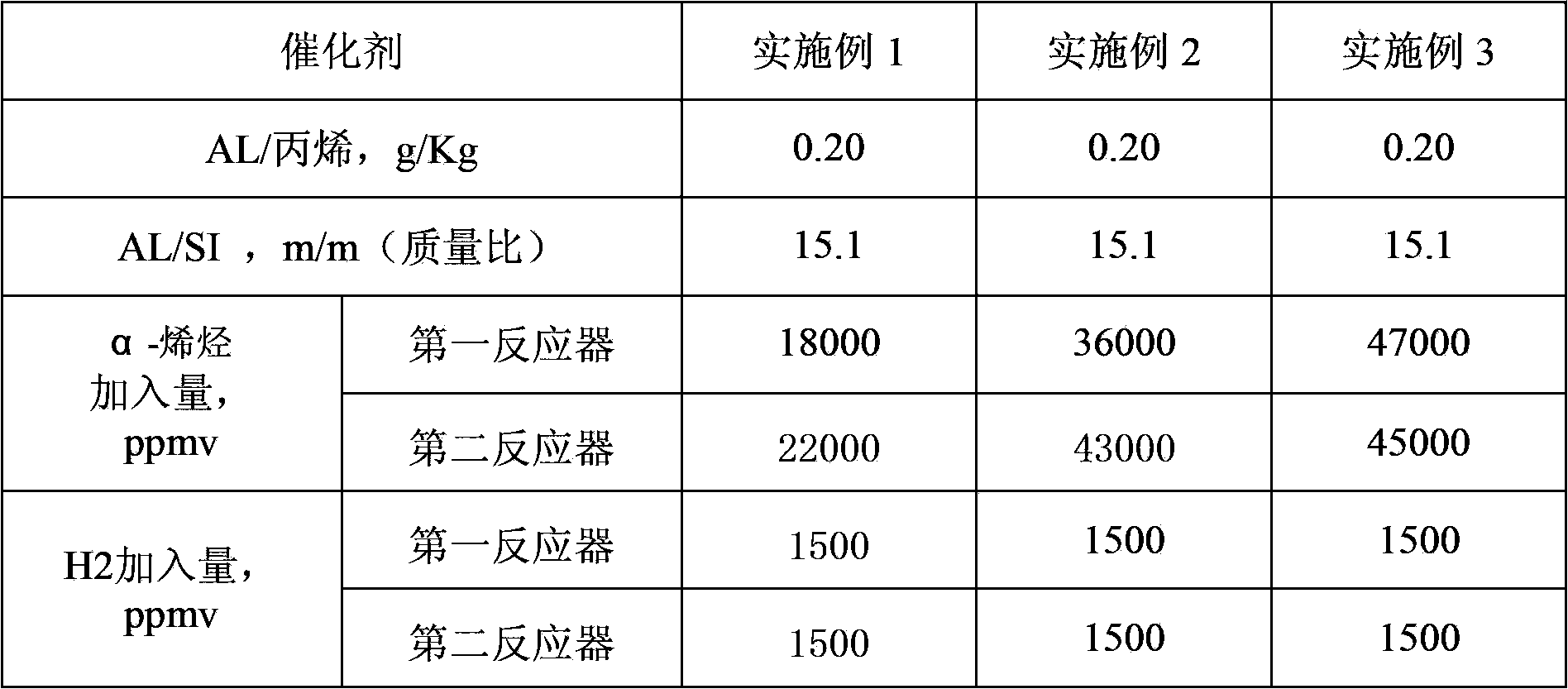

[0046] The polymerization reaction was carried out on a set of pilot plant. Its main equipment includes a prepolymerization reactor, a first loop reactor and a second loop reactor. The polymerization method and steps are as follows:

[0047] Pre-polymerization reaction:

[0048] The main catalyst (active solid catalyst component containing titanium) was obtained by the method described in Example 1 in Chinese patent CN93102795.0, and the internal electron donor compound was diisobutyl phthalate. The obtained main catalyst Ti content 2.2wt%, the content of diisobutyl phthalate is 11.2wt%.

[0049] The main catalyst, co-catalyst (triethylaluminum), and external electron donor (methylcyclohexyldimethoxysilane) are pre-contacted at 10°C for 20 minutes, and then continuously added to the pre-polymerization reactor for pre-polymerization. The polymerization is carried out in the bulk environment of the liquid phase of propylene, the temperature is 15°C, and the residence time is about 4...

Embodiment 2

[0055] Same as Example 1, except that the amount of α-olefin added is changed, and the specific process conditions are shown in Table 1.

Embodiment 3

[0057] Same as Example 1, except that the amount of α-olefin added is changed, and the specific process conditions are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com