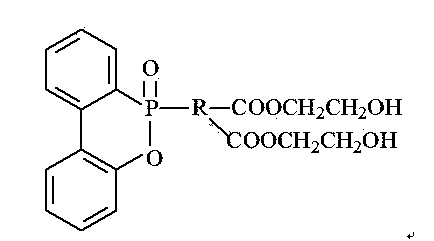

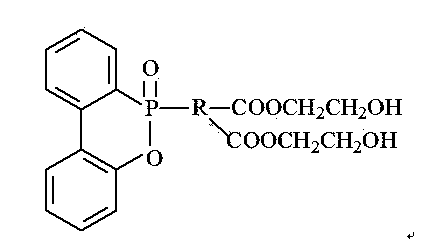

Phosphorus-containing flame retardant and preparation method thereof

A phosphorus flame retardant and flame retardant technology are applied in the field of phosphorus-containing flame retardants and their preparation, which can solve the problems of easy self-polymerization and easy formation of cyclic by-products, etc. The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

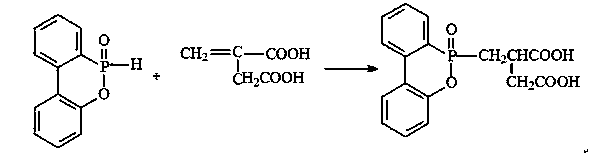

[0023] In a 200ml four-neck flask, add 21.6g (0.1mol) DOPO, 15.6g (0.12mol) methylenesuccinic acid, and 100ml toluene to react at 110°C for 5 hours to generate a dicarboxylic acid derivative of DOPO, suction filtration, A white solid was obtained, which was dried. The obtained solid was added to a 200ml four-necked flask at 40°C, 11.2g (0.2mol) of KOH was dissolved in 100ml of water, added to the four-necked flask, stirred for 2 hours, and 0.4g of dodecyltrimethyl chloride was added. Ammonium and 34.4g (0.2mol) 2-iodoethanol, after the reaction for 5 hours, pour the product of the four-necked bottle into a separatory funnel, let stand for stratification, the lower layer is a colorless and transparent product, the upper layer is a water layer, twelve The alkyl trimethyl ammonium chloride and the resulting KI are in the aqueous phase. The product has a purity of 94.5% and a viscosity of 519.5 mPa.s.

[0024] The reaction equation of the present embodiment is as follows:

[00...

Embodiment 2

[0030] Add 21.6g (0.1mol) DOPO, 11.6g (0.1mol) maleic acid, and 100ml toluene to a 200ml four-necked bottle and react at 110°C for 6 hours to generate a dicarboxylic acid derivative of DOPO, and suction filtration to obtain White solid, dried. The obtained solid was added to a 200ml four-necked flask at 30°C, 11.2g (0.2mol) of KOH was dissolved in 100ml of water, added to the four-necked flask, stirred for 2 hours, 0.4g of benzyltriethylammonium chloride and 16.1g (0.2mol) 2-chloroethanol, after 8 hours of reaction, pour the product of the four-necked bottle into a separatory funnel, let stand for stratification, the lower layer is a colorless and transparent product, the upper layer is a water layer, benzyl triethyl The base ammonium chloride and the resulting KCl are in the aqueous phase. The product has a purity of 92.6% and a viscosity of 537.0 mPa.s.

Embodiment 3

[0032] In a 200ml four-necked flask, add 21.6g (0.1mol) DOPO, 12.8g (0.11mol) fumaric acid, and 100ml toluene to react at 110°C for 3 hours to generate a dicarboxylic acid derivative of DOPO, and suction filtration to obtain White solid, dried. The obtained solid was added to a 200ml four-necked flask at 10°C, 11.2g (0.2mol) of KOH was dissolved in 100ml of water, added to the four-necked flask, stirred for 2 hours, 0.4g of tetrabutylammonium chloride and 25.0g of tetrabutylammonium chloride were added. (0.2mol) 2-bromoethanol, pour the product of the four-necked bottle into a separatory funnel after 6 hours of reaction, let stand for stratification, the lower layer is a colorless and transparent product, the upper layer is an aqueous layer, tetrabutylammonium chloride and the resulting KBr in the aqueous phase. The product has a purity of 93.4% and a viscosity of 526.0 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com