A kind of screen printing waterproof adhesive for thin film circuit and preparation method thereof

A technology of screen printing and thin film circuit, which is applied in the field of electronic paste, can solve the problems of affecting the service life of thin film circuit, the decrease of the adhesion force of waterproof adhesive, and the deterioration of the transparency of waterproof adhesive, so as to achieve superior printing performance, increase service life, Easy to apply repeatedly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

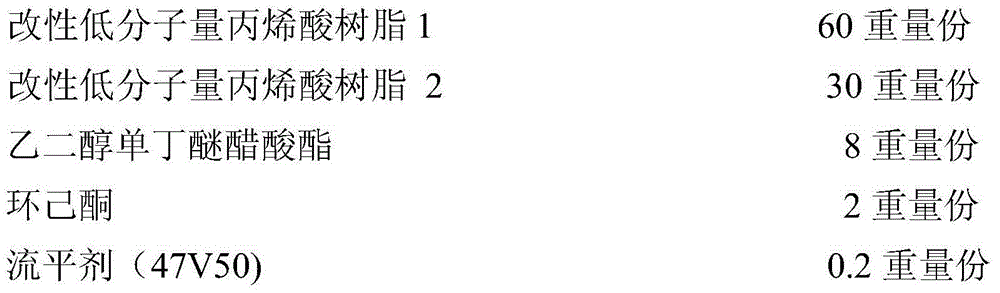

Embodiment 1

[0030] The preparation method of screen printing waterproof glue in this embodiment is as follows:

[0031] (1) Add 14 kg of commercially available high carboxyl value and low hydroxyl value acrylic resin pressure-sensitive adhesive (brand SH-602, product of Jiangyin Shuanghua Technology Co., Ltd.) and 1.2 kg of ethylene glycol monobutyl ether acetate into a three-necked flask, heat Stir and distill to remove about 1.8kg of the fraction below 155°C in the system, change to condensing and reflux, control the temperature at 150-160°C, add 58g of organic peroxide 1,1-bis-(tert-butyl peroxy)-3,3, 5-Trimethylcyclohexane was diluted to 50wt% with ethylene glycol monobutyl ether acetate, slowly added dropwise to the above system, and the dropping speed was controlled to be 2 seconds / drop. The obtained solid content is 56.8%, and the obtained modified low molecular weight acrylic resin 1 is adjusted to 50% with ethylene glycol monobutyl ether acetate, and adopts a BROOKFIELD viscomete...

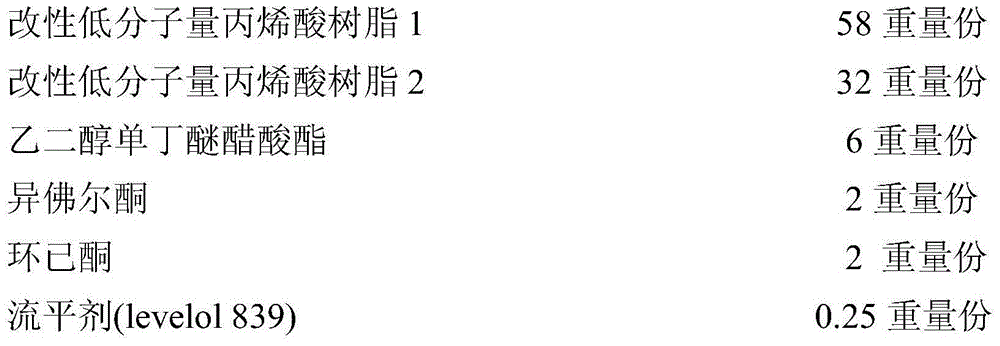

Embodiment 2

[0037] (1) Add 14kg of commercially available high carboxyl value and low hydroxyl value acrylic resin pressure-sensitive adhesive (brand SH-602 Jiangyin Shuanghua Technology Co., Ltd.) and 1.2kg of ethylene glycol monobutyl ether acetate into a three-necked flask, heat, stir and distill Remove about 1.8kg of the fraction below 155°C in the system, change to condensing and reflux, control the temperature at 150-160°C, and add 58g of organic peroxide 1,1-bis-(tert-butyl peroxy)-3,3,5- Trimethylcyclohexane was diluted to 50wt% with ethylene glycol monobutyl ether acetate, slowly added dropwise to the above-mentioned system, and the rate of addition was controlled to be 2 seconds / drop. The obtained modified low-molecular-weight acrylic resin 1 is adjusted to 50% with ethylene glycol monobutyl ether acetate, and the BROOKFIELD viscometer is used to measure the viscosity at 20 revolutions using No. 14 rotor to measure the viscosity It is 5500mpa.s.

[0038](2) Add 24kg of commerci...

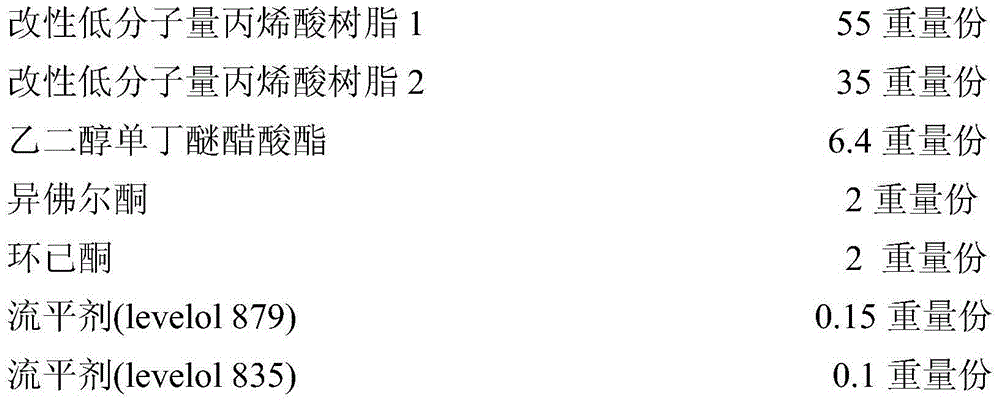

Embodiment 3

[0043] (1) Add 14 kg of commercially available high carboxyl value and low hydroxyl value acrylic resin pressure-sensitive adhesive (brand CF-2, Weifang Fule New Material Co., Ltd.) and 1.2 kg of ethylene glycol monobutyl ether acetate into a three-necked flask, heat Stir and distill to remove about 1.8kg of the fraction below 155°C in the system, change to condensing and reflux, control the temperature at 150-160°C, add 62g of organic peroxide 1,1-bis-(tert-butyl peroxy)-3,3, 5-Trimethylcyclohexane was diluted to 50wt% with ethylene glycol monobutyl ether acetate, slowly added dropwise to the above system, and the dropping speed was controlled to be 2 seconds / drop. The obtained solid content is 57.4%, and the gained modified low molecular weight acrylic resin 1 is adjusted to 50% with ethylene glycol monobutyl ether acetate, adopts BROOKFIELD viscometer, uses No. 14 spindles to measure the viscosity when 20 turns, measure The resulting viscosity is 5875mpa.s.

[0044] (2) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com