Clay anti-swelling stabilizer as well as preparation method and application thereof

A stabilizer and anti-swelling technology, applied in the field of clay anti-swelling stabilizer for oilfield and its preparation, can solve the problem of unsatisfactory application effect in cold region and low temperature zone, poor anti-swelling ability of anti-swelling agent, serious casing damage and layered water injection and other problems, to achieve the effect of improving oil recovery, ensuring normal and stable production, and high anti-swelling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

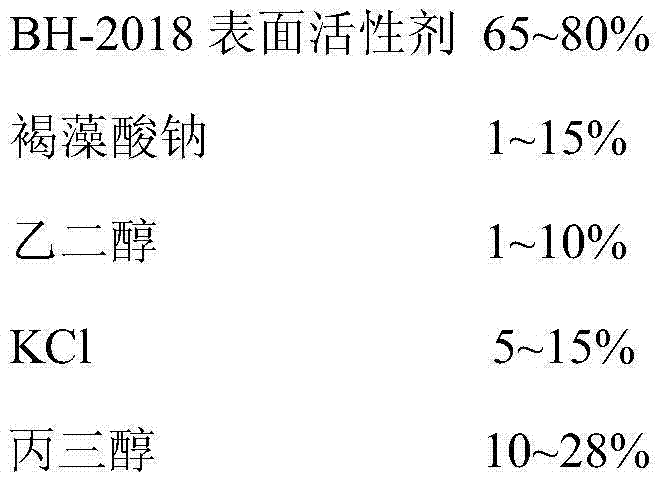

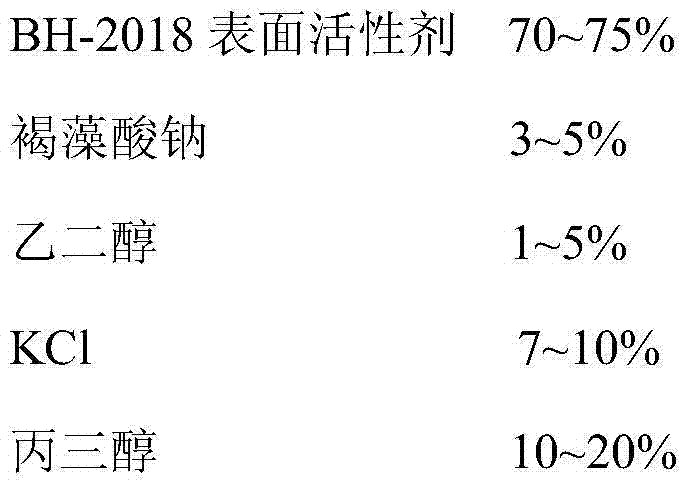

Method used

Image

Examples

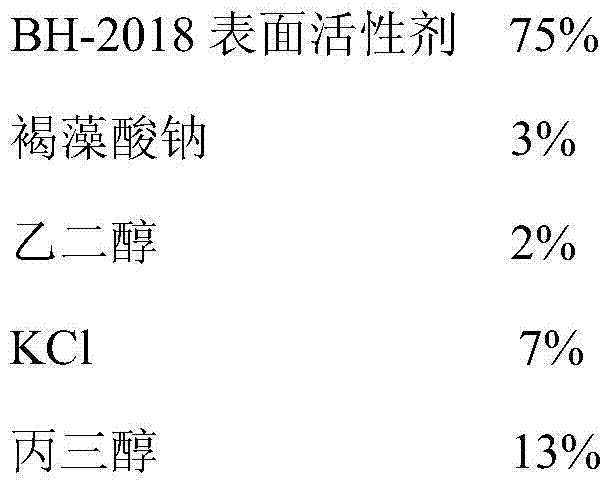

Embodiment 1

[0030] Weigh 71kg of BH-2018 surfactant, 7kg of sodium alginate, 2kg of ethylene glycol, 7kg of KCl and 13kg of glycerol, add BH-2018 surfactant, sodium alginate and ethylene glycol at room temperature and pressure In a sealed pressure reactor, start stirring, gradually raise the temperature to 60° C., and react for 2 hours. The mixture obtained by the reaction was cooled to 20° C., KCl and glycerol were added, and the stirring reaction was continued for 0.5 hours to obtain 100 kg of the clay anti-swelling stabilizer of the present invention. Store the packaging.

Embodiment 2

[0032] Weigh 75kg of BH-2018 surfactant, 3kg of sodium alginate, 2kg of ethylene glycol, 7kg of KCl, and 13kg of glycerol, and add BH-2018 surfactant, sodium alginate, and ethylene glycol into the airtight container at room temperature and pressure. In the pressure reactor, start stirring, gradually raise the temperature to 100°C, and react for 0.5 hours. The temperature of the reaction mixture was lowered to 15° C., KCl and glycerol were added, and the stirring reaction was continued for 1 hour to obtain 100 kg of the clay anti-swelling stabilizer of the present invention. Store the packaging.

Embodiment 3

[0034] Weigh 75kg of BH-2018 surfactant, 6kg of sodium alginate, 1.5kg of ethylene glycol, 6.5kg of KCl and 11kg of glycerol, and place BH-2018 surfactant, sodium alginate, and ethylene glycol at room temperature and pressure Add it into the airtight pressure reactor, start stirring, gradually raise the temperature to 80°C, and react for 10 hours. The temperature of the reaction mixture was lowered to 30° C., KCl and glycerol were added, and the stirring reaction was continued for 0.5 hours to obtain 100 kg of the clay anti-swelling stabilizer of the present invention. Store the packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com