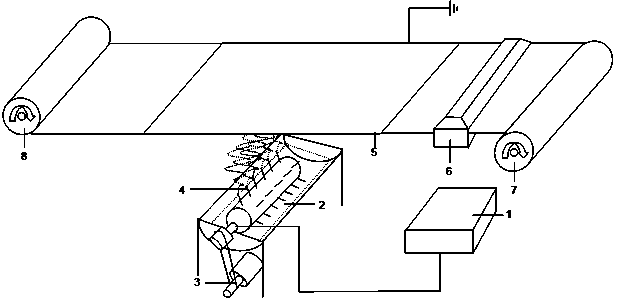

Device for producing nanofiber nonwoven fabric through multi-needle roller type high-voltage electrostatic spinning

A high-voltage electrostatic, nanofiber technology, applied in fiber processing, non-woven fabrics, textiles and papermaking, etc., to achieve the effects of high felt quality, increased output, and reduced industrial production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

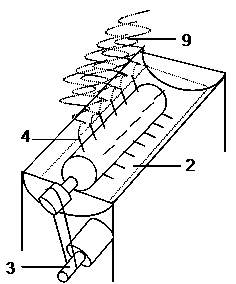

[0019] Embodiment 1: The preparation method of PVDF nanofibers according to the present invention is as follows: at room temperature, slowly dissolve PVDF copolymer pellets in N, N-dimethylformamide (DMF) solvent to prepare a 10% (weight percent) PVDF copolymer / PVDF solution. Then put the solution into the electrospinning liquid storage tank 2, start the high-voltage power supply 1, and drive the transmission device 3 to rotate the spinning barrel 4 (customized by Meike Haze Company) at a speed of about 0.1-2 cycles per second, and the multi-needle drum Fibers are ejected from the metal needle tip of the spinneret system. A 25 kV positive high voltage (Glassmann High Voltage) was applied to the multi-needle barrel spinning system. The distance from the metal needle tip of the multi-needle drum spinning system to the winding device composed of the cloth receiving roller 7 and the cloth releasing roller 8 is 15 cm. Under these conditions, a steady, tiny electrostatic jet will ...

Embodiment 2

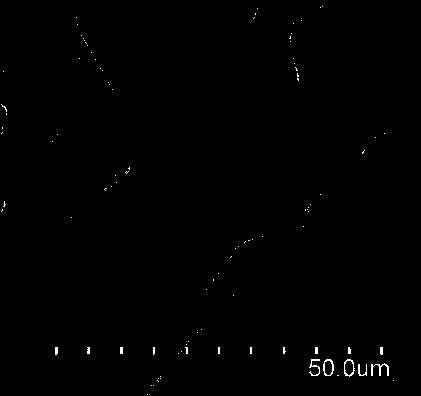

[0020] Embodiment 2: according to the PAN fiber membrane prepared by the present invention, its preparation process is as follows: the preparation of 12% (weight percentage) polyacrylonitrile (PAN) (Sinopharm Chemical Company) / DMF solution is to polymer powder slowly at room temperature Add and dissolve into DMF (N,N-dimethylformamide) organic solvent. After the solution is completely mixed, put it into the electrospinning liquid storage tank 2, start the high-voltage power supply 1, and start the motor to rotate the spinning barrel 4 (customized by Meike Haze Company) at a speed of about 0.1-2 cycles per second, and the multi-needle drum Fibers are ejected from the metal needle tip of the spinneret system. A 25 kV positive high voltage (Glassmann High Voltage) was applied to the multi-needle barrel spinning system. The distance from the metal needle tip of the multi-needle drum spinning system to the cloth receiving roller 7 and the cloth releasing roller 8 device is 15 cm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com