Mold powder for slab continuous casting mold and production method thereof

A technology of mold flux and slab continuous casting, applied in the field of metallurgical auxiliary materials, can solve the problems of instability, easy to separate melting, reduce the types of base materials, etc., achieve high added value, save mining, reduce a lot of accumulation and Effects of severe pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

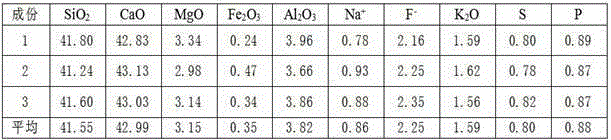

[0029] The formula of yellow phosphorus waste residue in the above-mentioned production process can be shown in the following table:

[0030]

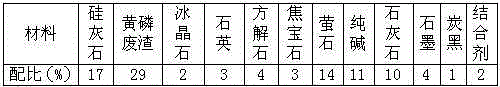

[0031] If conventional raw materials are used, the formula is shown in the table below:

[0032]

[0033] From the comparison of the above data, it can be seen that 29% of yellow phosphorus waste slag replaces 22% of wollastonite, 3% of cryolite, 3% of fluorite, 6% of limestone, 2% of burnt gemstone in the conventional formula, and 4% of Calcite, 3% Quartz. The raw material cost of the conventional raw material formula is 1315.6 yuan / ton, and the yellow phosphorus waste residue is calculated at 350 yuan / ton. The raw material cost of the yellow phosphorus waste residue formula is 1058.3 yuan / ton, and the raw material cost is reduced by 257.3 yuan / ton.

[0034] In the process ③ in the batching and slurry making, the slurry making time is 65min, and the water content of the slurry is 27%; ④The pump pressure of the spray granulation...

Embodiment 2

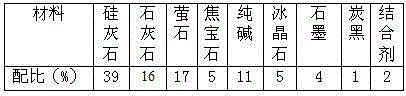

[0037] The formula of yellow phosphorus waste residue in the above-mentioned production process can also be shown in the following table:

[0038]

[0039] If conventional raw materials are used, the formula is shown in the table below:

[0040]

[0041] From the comparison of the above data, it can be seen that 27% of yellow phosphorus waste slag replaces 1.5% of cryolite, 28% of wollastonite, 2% of burnt gemstone, and 4.5% of quartz in the conventional formula. The raw material cost of the conventional raw material formula is 1386 yuan / ton, and the yellow phosphorus waste residue is calculated at 350 yuan / ton. The raw material cost of the yellow phosphorus waste residue formula is 1167.65 yuan / ton, and the raw material cost is reduced by 218.35 yuan / ton.

[0042] In the process ③ in the batching and pulping, the pulping time is 70min, and the water content of the slurry is 29%; ④The pump pressure of the spray granulation plunger pump is 2.3MPa, the liquid supply rate i...

Embodiment 3

[0045] The formula of yellow phosphorus waste residue in the above-mentioned production process can also be shown in the following table:

[0046]

[0047] If conventional raw materials are used, the formula is shown in the table below:

[0048]

[0049] From the comparison of the above data, it can be seen that 24% of yellow phosphorus waste slag replaces 11% of wollastonite, 8% of glass stone, 3% of fluorite, 2% of cryolite, 3% of calcite in the conventional formula, and 3% of Quartz; the raw material cost of the conventional raw material formula is 1327.3 yuan / ton, the yellow phosphorus waste residue is calculated at 350 yuan / ton, the raw material cost of the yellow phosphorus waste residue formula is 1087.6 yuan / ton, and the raw material cost is reduced by 239.7 yuan / ton.

[0050] In the process ③ in the batching and pulping, the pulping time is 75min, and the water content of the slurry is 31%; ④The pump pressure of the spray granulation plunger pump is 2.5MPa, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com