Centralized lubrication system of hydraulic station

A centralized lubrication and hydraulic station technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of dry friction reducing the accuracy and life of friction pairs, additional heat, environmental pollution, energy waste, etc. Achieve long service life, good interchangeability and versatility, and good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

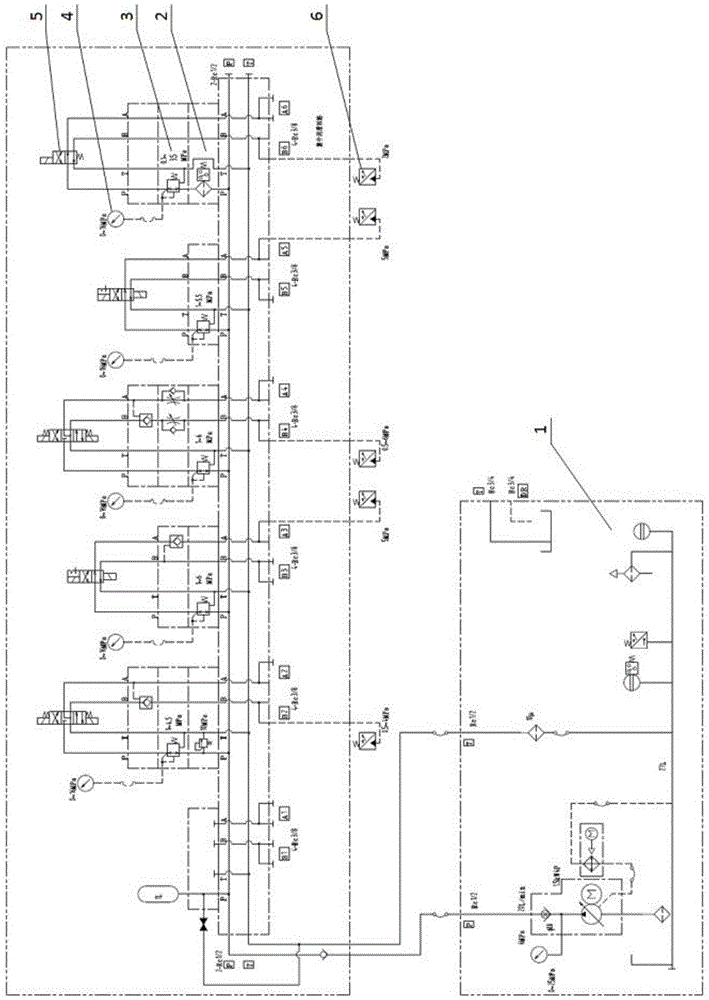

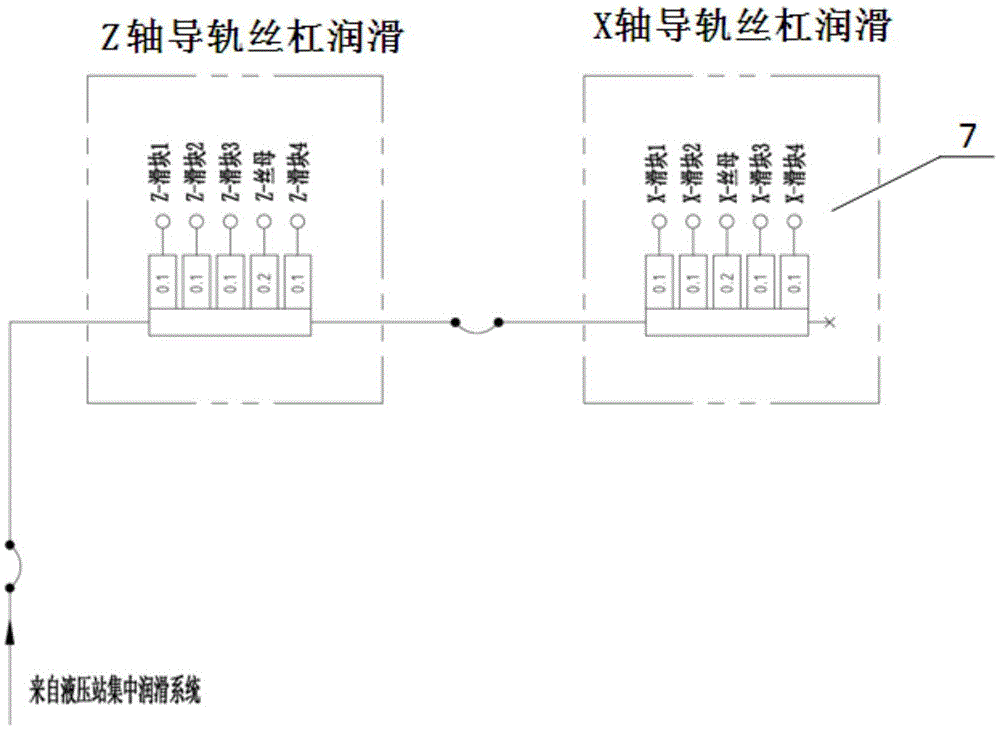

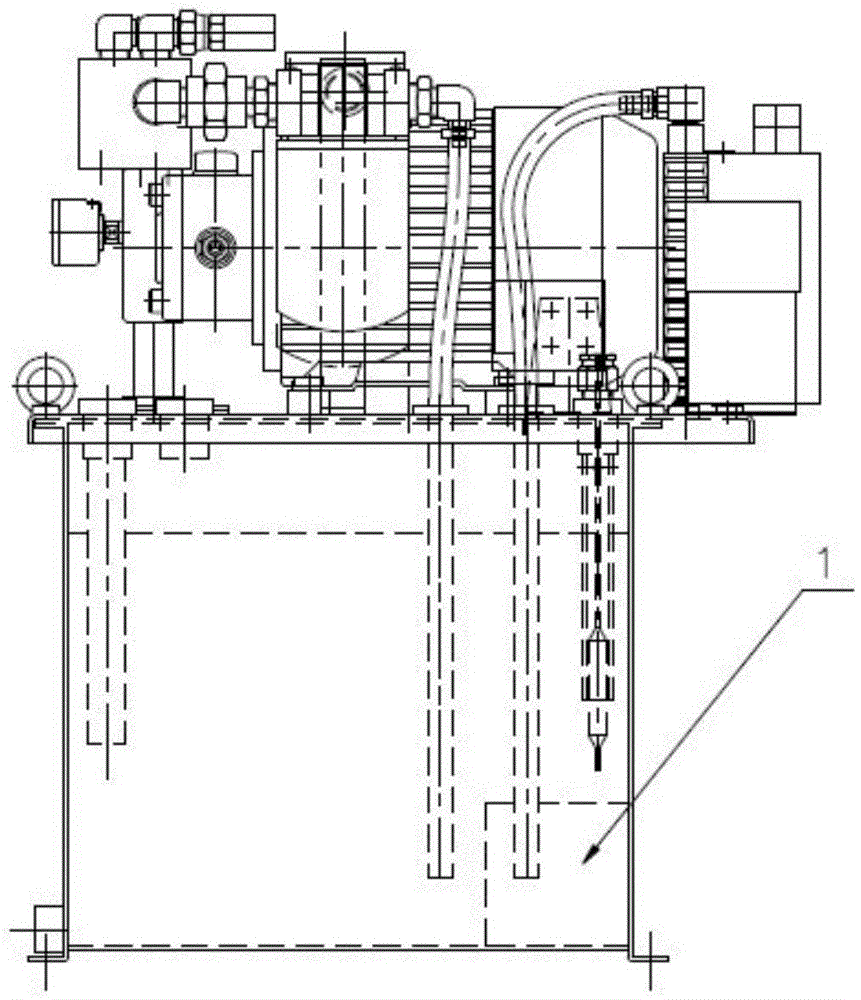

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 4 As shown, the present invention includes a hydraulic station 1, a stacked filter 2, a pressure reducing valve 3, a pressure gauge 4, a reversing valve 5, a pressure relay 6, a pressurized quantitative oiling distributor 7, pipelines and joints, etc.; Table 4 is connected to the pressure reducing valve 3; the reversing valve 5 is connected to the pressure reducing valve 3 and the oil return pipe respectively; the hydraulic oil is extruded from the pump station of the hydraulic station 1 and flows through the superimposed filter 2, and the hydraulic oil is finely filtered and then The pressure oil in the hydraulic system is reduced to the suitable oil pressure of the lubrication system by the pressure reducing valve 3, and then the oil is delivered to the pressurized quantitative oil injection distributor 7 through the reversing valve 5; The lubricating oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com