Beta molecular sieve synthesizing method

A molecular sieve and seed crystal technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of difficult industrialized production, uneven stirring, etc., and achieve the effects of reducing production costs, simple and easy operation, and reducing crystallization reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

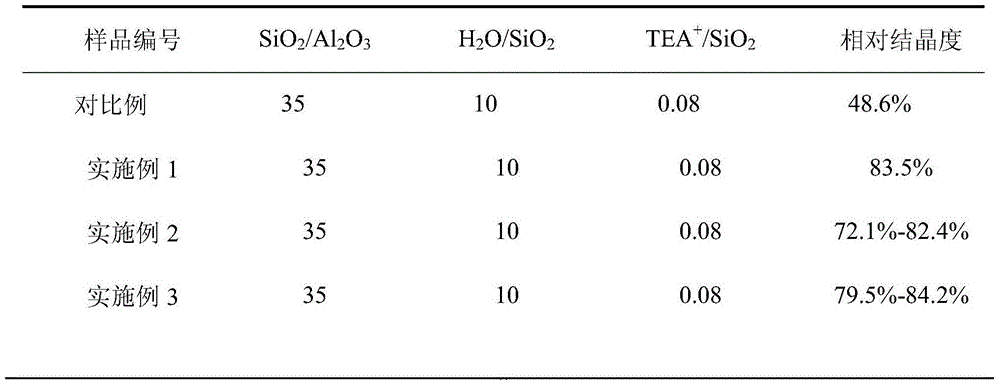

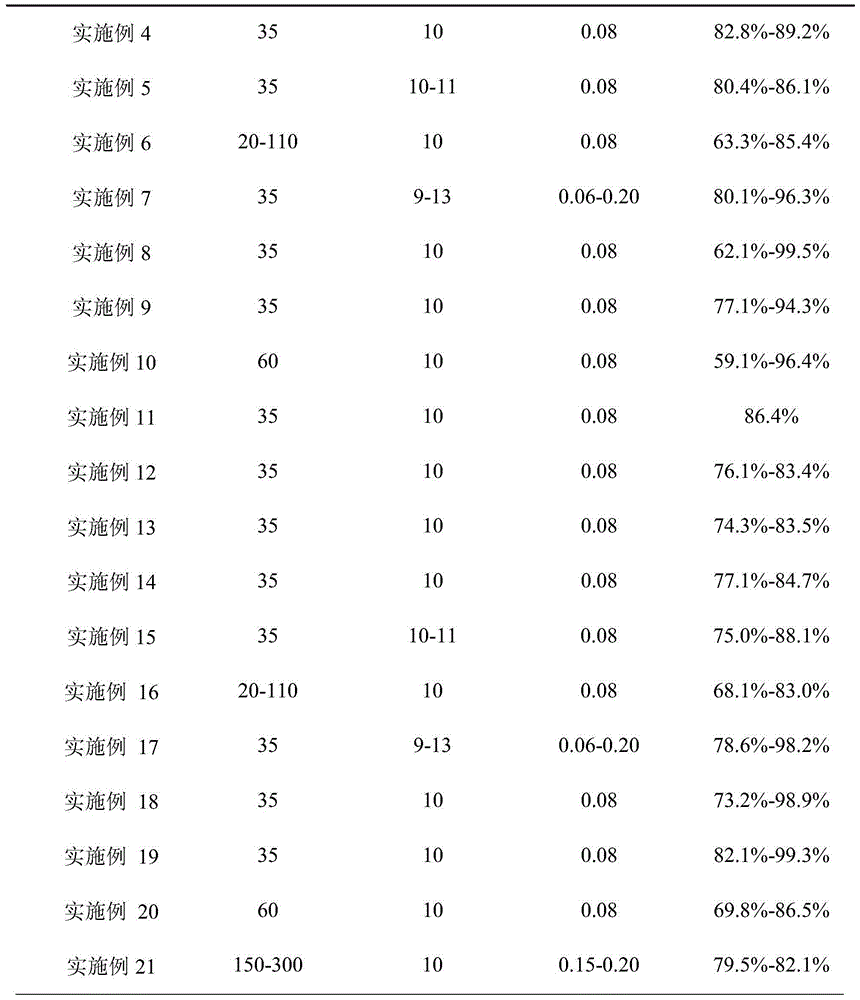

Embodiment 1

[0039] (1) Treat Beta molecular sieve seed crystals with ammonium fluoride: prepare 20ml of 10wt% ammonium fluoride solution, add 5g Beta molecular sieve seed crystals, heat and stir in a water bath at 70°C for 4 hours to obtain suspension A.

[0040] (2) Take 12g TEAOH solution (industrial grade, TEAOH≥25wt%) and 1.5g NaAlO 2 Solid (chemically pure, Al 2 o 3 , 49wt%) stirring the preparation solution, adding 50g silica sol (industrial grade, SiO 2 ≥30wt%), mixed uniformly to form silica-alumina gel, wherein the molar ratio of each material is: SiO 2 / Al 2 o 3 = 35, TEA + / SiO 2 =0.08,H 2 O / SiO 2 =10. Add 3 g of the well-stirred suspension A to the silica-alumina gel, suspension A / silicon-alumina gel=4.7wt%. After continuing to stir for 30 minutes, put it into a stainless steel reaction kettle, seal it at 150°C and crystallize for 18 hours to obtain a milky white suspension B.

[0041] (3) Suspension B was filtered and washed, dried at 110°C for 6 hours, and calcine...

Embodiment 2

[0044] Repeat Example 1, change the concentration of Beta molecular sieve seed crystal seed pretreatment liquid ammonium fluoride in step (1), change to 5wt%, 14wt%, 18wt% respectively, other conditions are constant; The product crystalline phase that obtains is Beta Molecular sieves have relative crystallinity of 72.1%, 82.4%, and 80.5%, respectively.

Embodiment 3

[0046] Repeat Example 1, change the temperature and time of Beta molecular sieve seed crystal seed pretreatment liquid ammonium fluoride in step (1), respectively change to 60 ℃, 5 hours; 80 ℃, 3 hours; 90 ℃, 1 hour, other conditions The crystal phases of the obtained products are all Beta molecular sieves, and their relative crystallinities are 79.5%, 81.8%, and 84.2%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com