A method and equipment for recycling fluoride in the production of zirconium-containing compounds

A zirconium compound and fluoride technology, applied in zirconia and other directions, can solve the problems of polluting the environment, reducing the utilization rate of fluorine-containing compounds, etc., and achieving the effect of repeated recycling and reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

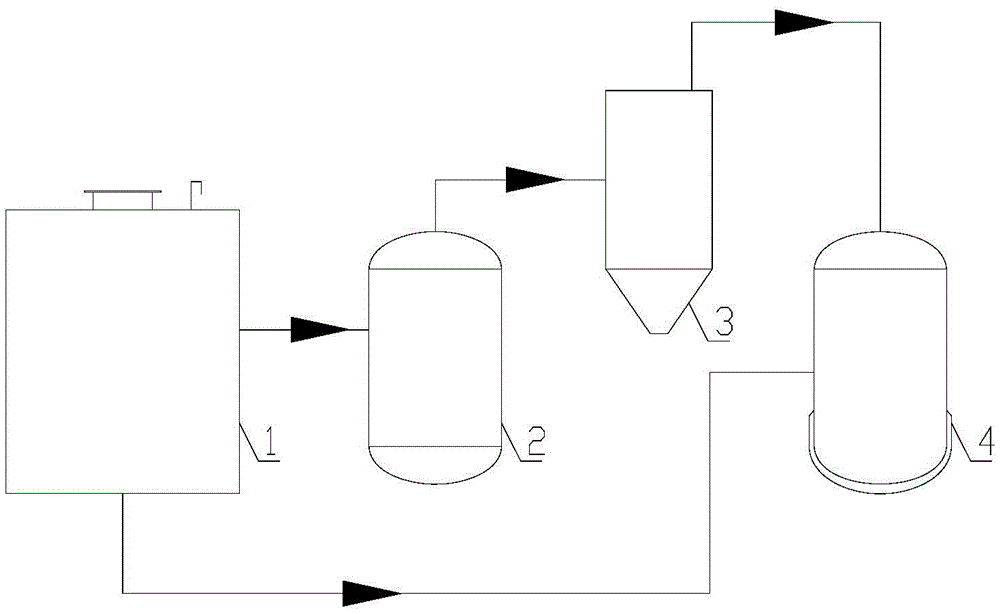

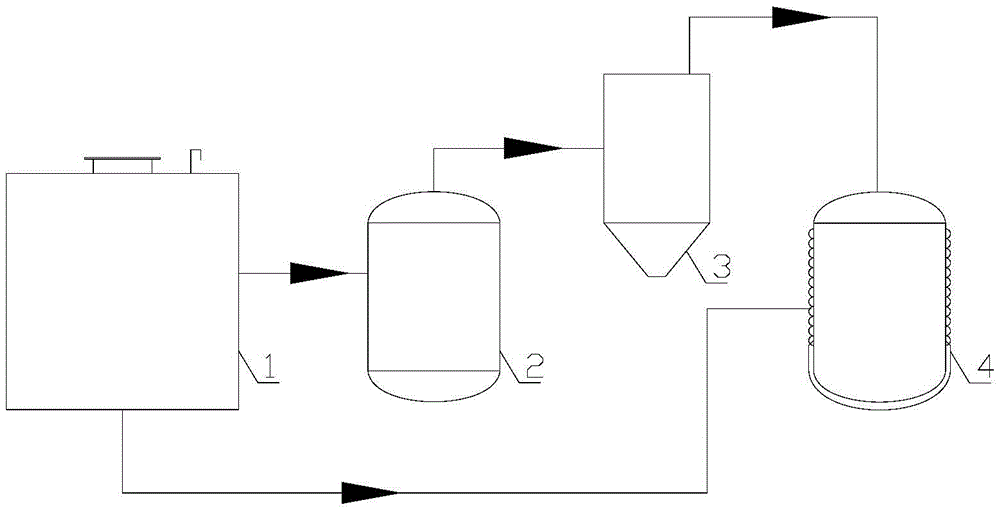

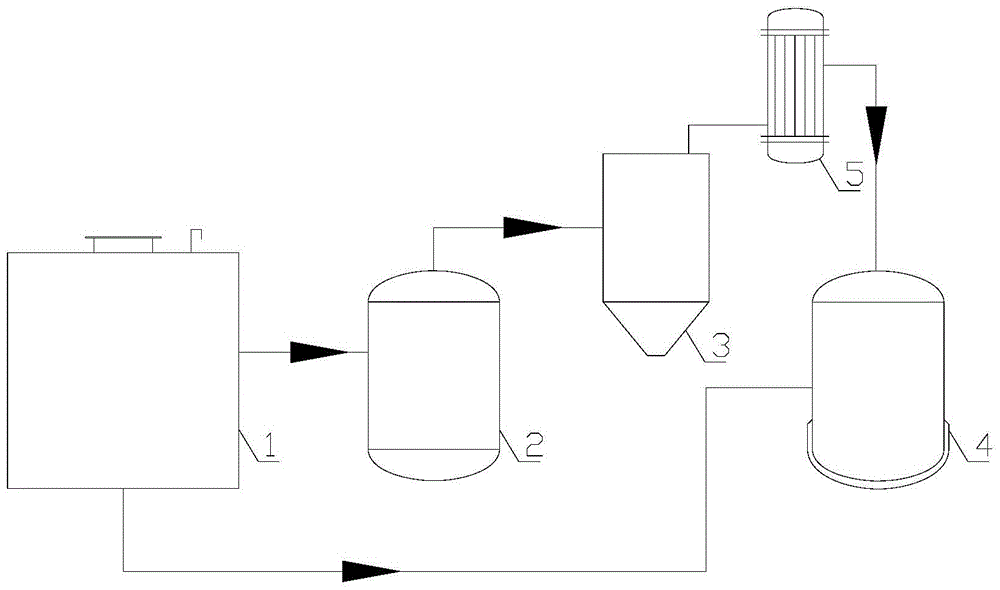

Image

Examples

Embodiment 1

[0065] will contain ZrO 2 waste with CaF 2 Mix well to get a mixture, ZrO 2 with CaF 2 The particle size is below 3mm, the CaF in the resulting mixture 2 The mass percentage is 80%. Calcinate the mixture in the first reactor at 1150°C for 1 hour to generate CaO and ZrF 4 , ZrF 4 It is gaseous at high temperature and escapes from solid reactants. ZrF that will escape 4 Introduced into the second reactor and hydrolyzed at 900°C to generate ZrO 2 and HF gas. The HF gas produced by hydrolysis is transported to the third reactor with a polytetrafluoroethylene pipeline, and reacted with the reaction product CaO at 600°C for 2.5 hours to obtain CaF again. 2 , thus realizing CaF 2 of recycling. The reaction equation is as follows:

[0066] ZrO 2 +2CaF 2 →2CaO+ZrF 4 (4)

[0067] ZrF 4 +2H 2 O→ZrO 2 +4HF (5)

[0068] CaO+2HF→CaF 2 +H 2 O(6)

Embodiment 2

[0070] The baddeleyite (ZrO 2 mSiO 2 ) with AlF 3 Mix well to get a mixture, baddeleyite and AlF 3 The particle size is below 5mm, and the AlF in the resulting mixture 3 The mass percentage is 60%. The mixture was calcined at 1300°C for 3 hours in the first reactor to generate Al 2 o 3 and gaseous ZrF 4 and gaseous SiF 4 , the gaseous SiF 4 After being separated at low temperature, it is hydrolyzed to produce silicon dioxide and hydrogen fluoride. ZrF 4 Escape from the solid reactant by sublimation. ZrF that will escape 4 Introduced into the second reactor and hydrolyzed at 1000°C to generate ZrO 2 and HF gas. The HF gas produced by hydrolysis is transported to the third reactor with polytetrafluoroethylene pipeline, and the reaction product Al 2 o 3 After reacting at 100°C for 5 hours, AlF was recovered 3 , thus achieving AlF 3 of recycling. The reaction equation is as follows:

[0071] 3ZrO 2 +4AlF 3 →2Al 2 o 3 +3ZrF 4 (7)

[0072] 3SiO 2 +4AlF 3 ...

Embodiment 3

[0076] ZrO 2 Coarse particles and NH 4 HF 2 Mix well, ZrO 2 with NH 4 HF 2 The particle size is below 7mm, and the NH in the resulting mixture 4 HF 2 The mass percentage is 40%. The mixture was calcined at 600°C for 5 hours in the first reactor to generate NH 3 、H 2 O and ZrF 4 , ZrF 4 escaped from the solid. ZrF that will escape 4 Introduced into the second reactor and hydrolyzed at 500°C to generate ZrO 2 and HF gas. The HF gas produced by hydrolysis is transported to the third reactor with polytetrafluoroethylene pipeline, and the reaction product NH 3 and H 2 O was reacted at 150°C for 4.5 hours to regain NH 4 HF 2 , thus achieving NH 4 HF 2 of recycling. The reaction equation is as follows:

[0077] ZrO 2 +2NH 4 HF 2 →ZrF 4 +2NH 3 +2H 2 O(11)

[0078] ZrF 4 +2H 2 O→ZrO 2 +4HF (12)

[0079] NH 3 ·H 2 O+2HF→NH 4 HF 2 +H 2 O(13)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com