Special calcium fertilizer for rice and its preparation and method for producing calcium-enriched rice

A technology of rice and calcium fertilizer, applied in botany equipment and methods, rice cultivation, application, etc., can solve the problems of inability to achieve calcium fortification effect, unfavorable absorption, low utilization rate, etc., achieve high absorption and utilization rate of human body, and solve shortcomings Calcium problem, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The rice field in Dingyan Town, Rugao City, Jiangsu Province was selected as the fertilizer effect test field. The rice cultivar was Huaidao-7, which is widely planted in the plain area of the lower reaches of the Yangtze River. Each small test group was set to 7×19=133 square meters (0.2 mu ) of the residential area, build a ridge with a width of 0.5 meters around each residential area and keep a separation distance of 1 meter, and each residential area is equipped with a separate irrigation and drainage channel. Select one of the plots as a control group for conventional rice cultivation (do not add the special calcium fertilizer for rice of the present invention), and the group that adds the special calcium fertilizer for rice of the present invention adopts the same cultivation technique as the control group. Ears were threshed and rice milled, and the calcium content of the rice was measured, and the calcium content of the rice in the control group was measured to...

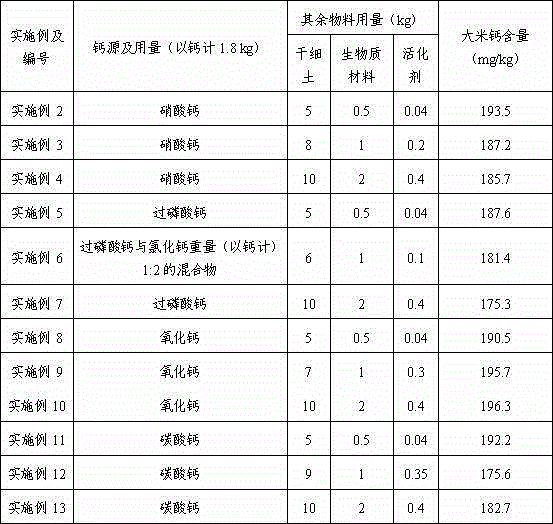

Embodiment 2-13

[0029] First, make a tray-type mold with the same specifications as the standard seedling tray, the size of the tray-type mold is: length 580mm, width 280mm, depth 10mm; biomass filling materials: rice straw, wheat straw, corn straw and The reeds are crushed into small pieces, and mixed with wood chips and rice husks at the same time; the dry fine soil, calcium source, and activator (a mixture of sulfur and humic acid 1:1) are respectively crushed into powders, and the particle size is less than 48 μm, of which nano The proportion of the grade is 5~15%, then roughly mix the calcium source powder, dry fine soil powder, activator powder and biomass filling material according to the ratio in the table below, then add it to the mixer and mix it well, and keep stirring during the mixing process Spray water to make it moist, the amount of said water accounts for 60% of the amount of dry fine soil, see the table below for details; put a piece of paper as large as the bottom of the tra...

Embodiment 14-20

[0034] First, make a tray-type mold with the same specifications as the standard seedling tray, the size of the tray-type mold is: length 580mm, width 280mm, depth 10mm; biomass filling materials: rice straw, wheat straw, corn straw and The reeds are crushed into small pieces, and mixed with wood chips and rice husks at the same time; the dry fine soil, calcium source, and activator (a mixture of sulfur and humic acid 1:1) are respectively crushed into powders, and the particle size is less than 48 μm, of which nano The proportion of grades is 5~15%, and then the calcium source powder (calculated as calcium 0.4~2.4kg, each group is weighed according to the amount in the table below), dry fine soil powder (7.5kg), small pieces of raw Substance filling material (1kg) and activator powder (0.25kg) are roughly mixed, then added to the mixer and fully mixed evenly. During the mixing process, water is continuously sprayed to make it moist. The amount of water accounts for 40% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com