Glucosamine chondroitin tablet containing active peptide and organic calcium and preparation method of glucosamine chondroitin tablet

A technology of plain tablets and active peptides, which is applied in the field of glucosamine chondroitin tablets and its preparation, can solve the problems of tablet mold damage, unfavorable large-scale production, and low absorption and utilization rate of calcium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 30

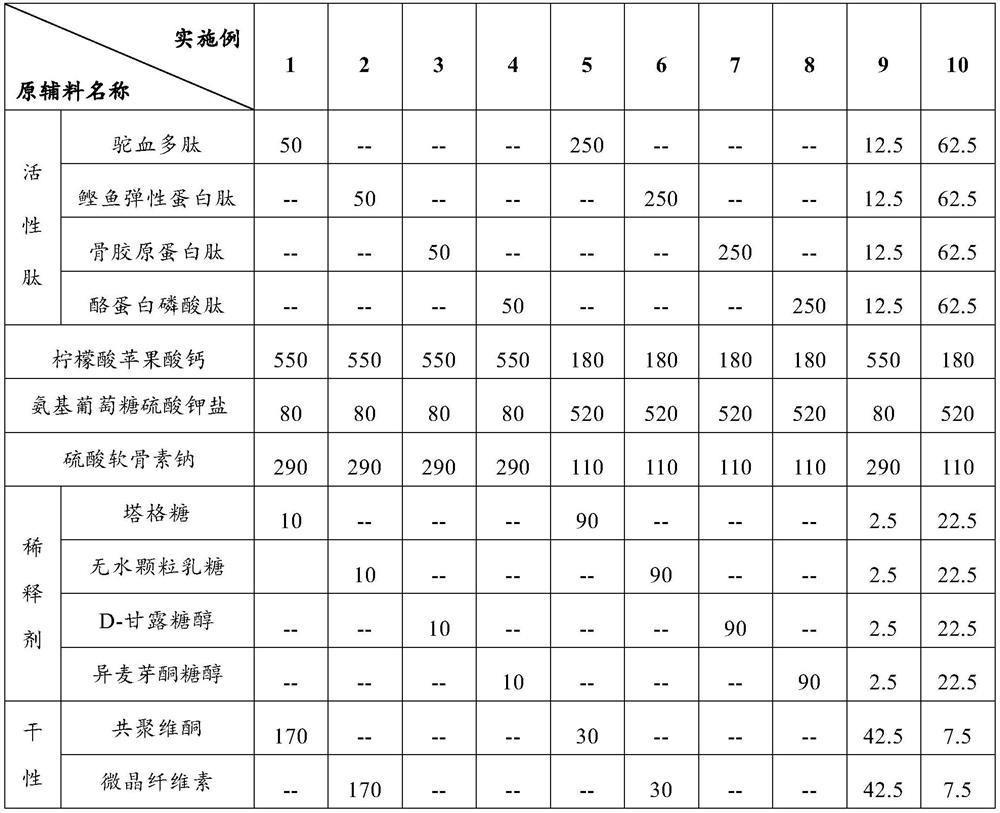

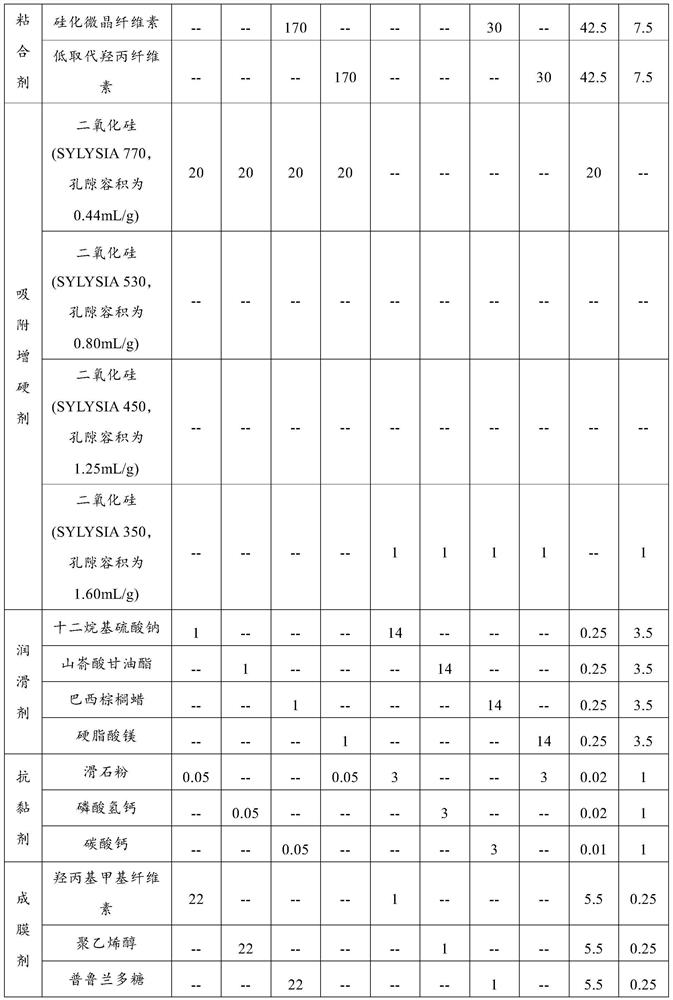

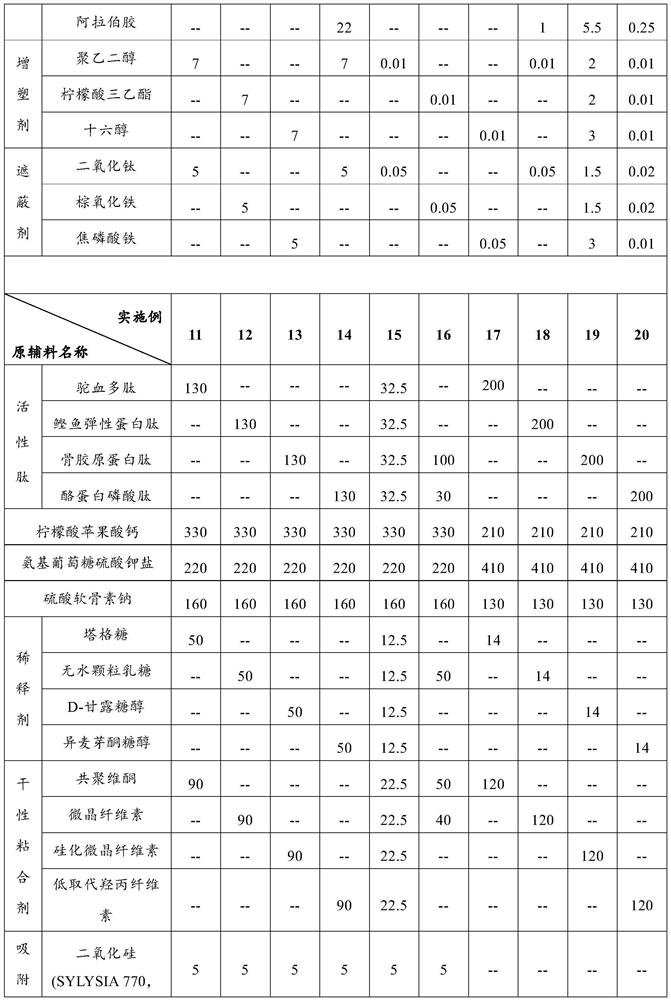

[0051] In the following examples 1-30, a glucosamine chondroitin tablet containing active peptide and organic calcium and its preparation method are provided. in,

[0052] Formula: the formula composition of the glucosamine chondroitin tablet containing active peptide and organic calcium is shown in Table 1.

[0053] Preparation method: Prepare the corresponding glucosamine chondroitin tablets containing active peptide and organic calcium according to the following method:

[0054] (1) Pass the active peptide, calcium citrate malate, diluent and dry adhesive through a 60-mesh sieve respectively, pass chondroitin sulfate sodium and lubricant through a 80-mesh sieve respectively, and pass the anti-sticking agent, film-forming agent, The plasticizer and masking agent are respectively passed through a 100-mesh sieve for subsequent use;

[0055] (2) Mix glucosamine sulfate potassium salt and adsorption hardening agent for 5 minutes at a rotating speed of 10 r / min to obtain materi...

Embodiment 31

[0071] Prescription: form with embodiment 16 prescription.

[0072] Preparation:

[0073] (1) Pass the active peptide, calcium citrate malate, sodium chondroitin sulfate, diluent, dry adhesive, and lubricant through a 40-mesh sieve respectively; Pass through 80-mesh sieve respectively, set aside;

[0074] (2) Mix glucosamine sulfate potassium salt and adsorption hardening agent for 2 minutes at a rotating speed of 10 r / min to obtain material I;

[0075] (3) Pass material I through a 50-mesh sieve, and mix for 3 minutes at a rotating speed of 20 r / min to obtain material II;

[0076] (4) Mix the sieved active peptide, calcium citrate malate, sodium chondroitin sulfate, diluent, dry adhesive, lubricant and material II at a speed of 5 r / min for 45 minutes to obtain the material III;

[0077] (5) The tablet hardness is controlled to be 80N, and the material III is pressed into tablets to obtain the material IV;

[0078] (6) Mix the anti-adhesive agent, film-forming agent, plas...

Embodiment 32

[0082] Prescription: form with embodiment 30 prescription.

[0083] Preparation method: (1) Pass the active peptide, calcium citrate malate, sodium chondroitin sulfate, diluent, dry adhesive and lubricant through an 80-mesh sieve respectively; and masking agent are respectively passed through a 400-mesh sieve for subsequent use;

[0084] (2) Mix glucosamine sulfate potassium salt and adsorption hardening agent for 8 minutes at a rotating speed of 20r / min to obtain material I;

[0085] (3) Pass material I through a 80-mesh sieve, and mix for 10 minutes at a rotating speed of 10 r / min to obtain material II;

[0086] (4) Mix the sieved active peptide, calcium citrate malate, sodium chondroitin sulfate, diluent, dry adhesive, lubricant and material II at a speed of 20r / min for 15 minutes to obtain the material III;

[0087] (5) The tablet hardness is controlled to be 250N, and material III is pressed into tablets to obtain material IV;

[0088] (6) Mix the anti-adhesive agent, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com