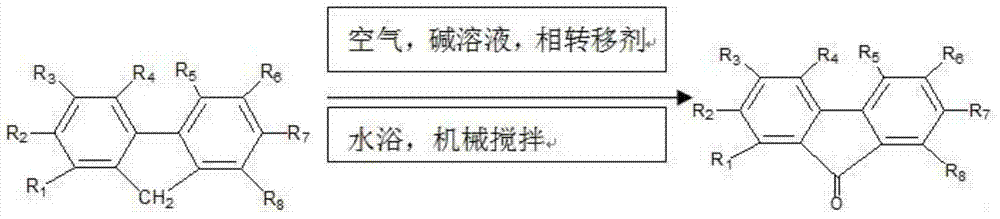

Method for preparing 9-fluorenone through fluorene

A technology of fluorenone and reaction, applied in the field of organic synthesis, can solve the problems of undisclosed types of quaternary ammonium salt, large solvent loss, high reaction temperature, etc., and achieve the effect of simplifying the synthesis process of fluorenone and simplifying the refining method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In a 250mL three-necked flask, sequentially add 60.42g of industrial fluorene, 62.87g of 9-fluorenone, 1.00g of tetrabutylammonium chloride, 6g of NaOH and 9mL of water, heat the three-necked flask in a water bath at 80°C, and control the mechanical stirring rate to 300r / min. 300×2mL / min air was bubbled through 80°C water and then entered into the reaction flask to start the reaction. During the reaction, the conversion of fluorene was monitored by thin-layer chromatography. After 10.5 hours of reaction, the raw material point disappeared, and the reaction was continued for half an hour to stop the reaction. The reaction liquid was transferred to warm water to cool while it was hot, stirred thoroughly, cooled, and filtered to obtain a yellow solid, which was dried naturally in air to obtain 124.46 g of 9-fluorenone. Chromatographic analysis showed that the content of 9-fluorenone was 97.01%, and the raw material fluorene was completely converted.

Embodiment 2

[0047] In a 250 mL three-necked flask, 61.86 g of industrial fluorene, 30 g of 9-fluorenone, and 1.20 g of tetrabutylammonium bromide were sequentially added, and the others were the same as in Example 1. After 8 hours of reaction, the raw material point disappeared, and the reaction was continued for half an hour to stop the reaction. A crude product of 92.86 g was obtained. Chromatographic analysis showed that the content of 9-fluorenone was 96.87%, and the raw material fluorene was completely converted.

Embodiment 3

[0049] In a 250 mL three-necked flask, 61.45 g of industrial fluorene, 45.44 g of 9-fluorenone, and 1.20 g of tetrabutylammonium hydrogen sulfate were successively added, and the others were the same as in Example 1. After 7.5 hours of reaction, the raw material point disappeared, and the reaction was continued for half an hour to stop the reaction, and 113.19 g of yellow crystals were obtained. Chromatographic analysis showed that the content of 9-fluorenone was 96.51%, and the raw material fluorene was completely converted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com