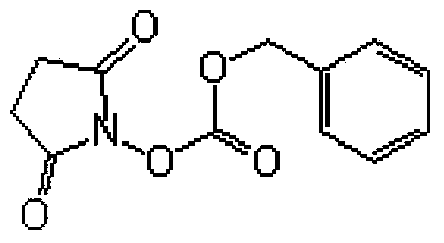

Method for preparing N-(carbobenzoxy) succinimide

A technology of hydroxysuccinimide and succinimide is applied in the field of preparation of N-(benzyloxycarbonyl)succinimide, which can solve the problems of poor purity and low product yield, and achieve good purity and reaction yield. High efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of N-(benzyloxycarbonyl) succinimide, the preparation method comprising the following steps:

[0023] (1) 57.5kg N-hydroxysuccinimide, 82.8kg K 2 CO 3 , 552kg of deionized water and 287.5kg of butyl acetate were dropped into a 1000-liter reactor.

[0024] (2) Cool with jacketed ice-salt water to an internal temperature of 9-10°C, add 85kg of benzyl chloroformate dropwise while stirring, and complete the addition within 2-3 hours. Continue to keep the internal temperature at 5-15°C for 1 hour after adding After the addition was complete, the reaction was continued for 1 h.

[0025] (3) Stop stirring after the reaction is over. After standing still for 1 hour, the lower layer of brine is released, and the upper layer of ethyl acetate remains in the reaction kettle. After stirring, add 287.5 kg of petroleum ether next time, and stir for another 1 hour at room temperature. A large amount of white solids are precipitated. .

[0026] (4) The wet produ...

Embodiment 2

[0028] A preparation method of N-(benzyloxycarbonyl) succinimide, the preparation method comprising the following steps:

[0029] (1) Mix 57.5kg N-hydroxysuccinimide, 34.5kg K 2 CO 3 , 690kg of deionized water and 57.5kg of butyl acetate were put into a 2000-liter reactor.

[0030] (2) Cool with jacket ice brine to an internal temperature of 0-9°C, add 68.2kg of benzyl chloroformate dropwise while stirring, and keep the internal temperature at 0-15°C after adding 68.2kg of benzyl chloroformate within 0.5 hours 5h, continue the reaction for 1h after the dropwise addition is completed.

[0031] (3) Stop stirring after the reaction is over. After standing for 1 hour, the lower layer of brine is released, and the upper layer of ethyl acetate remains in the reaction kettle. After stirring, 575 kg of petroleum ether is added next time, and stirred for another 1 hour at room temperature, and a large amount of white solids are precipitated.

[0032] (4) The wet product was obtained...

Embodiment 3

[0034] A preparation method of N-(benzyloxycarbonyl) succinimide, the preparation method comprising the following steps:

[0035] (1) Mix 57.5kg N-hydroxysuccinimide, 138kg K 2 CO 3 , 690kg of deionized water and 862.5kg of butyl acetate were put into a 3000-liter reactor.

[0036] (2) Control the temperature at 10-60°C, add 102.3kg of benzyl chloroformate dropwise while stirring, and continue to keep the internal temperature at 50-60°C for 0.5h after adding 102.3kg of benzyl chloroformate for 5 hours. Continue to react for 1h.

[0037] (3) Stop stirring after the reaction is over. After standing still for 1 hour, the lower layer of brine is released, and the upper layer of ethyl acetate remains in the reaction kettle. After stirring, add 1752 kg of petroleum ether next time, and stir for another 1 hour at room temperature, and a large amount of white solids precipitate out.

[0038] (4) The wet product was obtained by filtration, taken out after pressing, and dried in an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com