Wide-temperature domain high-shock absorbance sports footwear sole rubber material and its preparation method

A technology for rubber materials and sports shoes, applied in soles, footwear, applications, etc., can solve the problems of narrow damping temperature range, limitation of shock absorption performance of sole materials, and reduce material loss factor, etc., to achieve good wear resistance and shock absorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

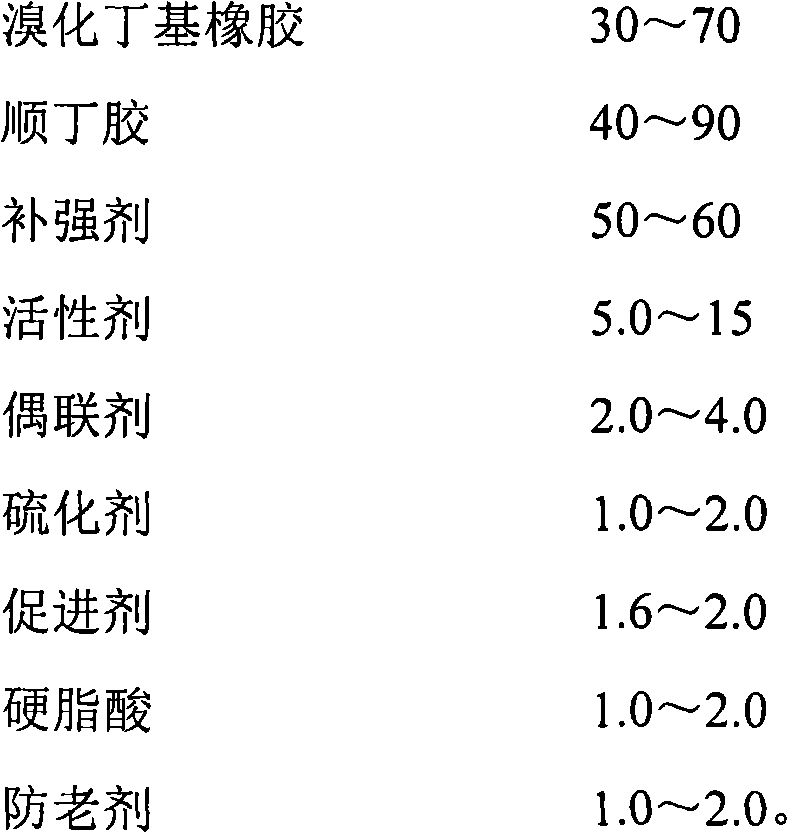

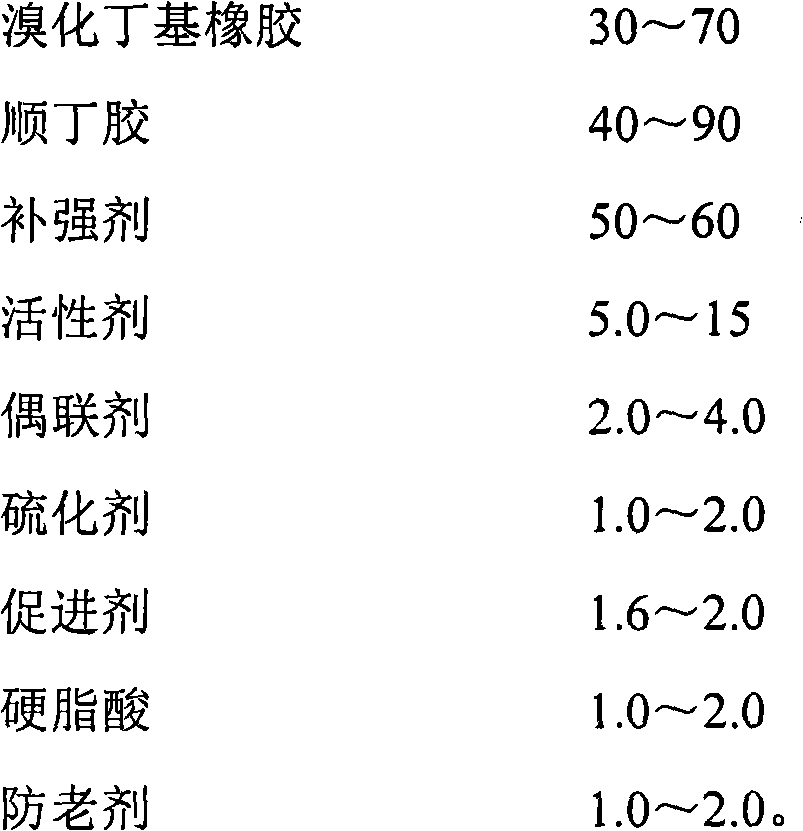

Method used

Image

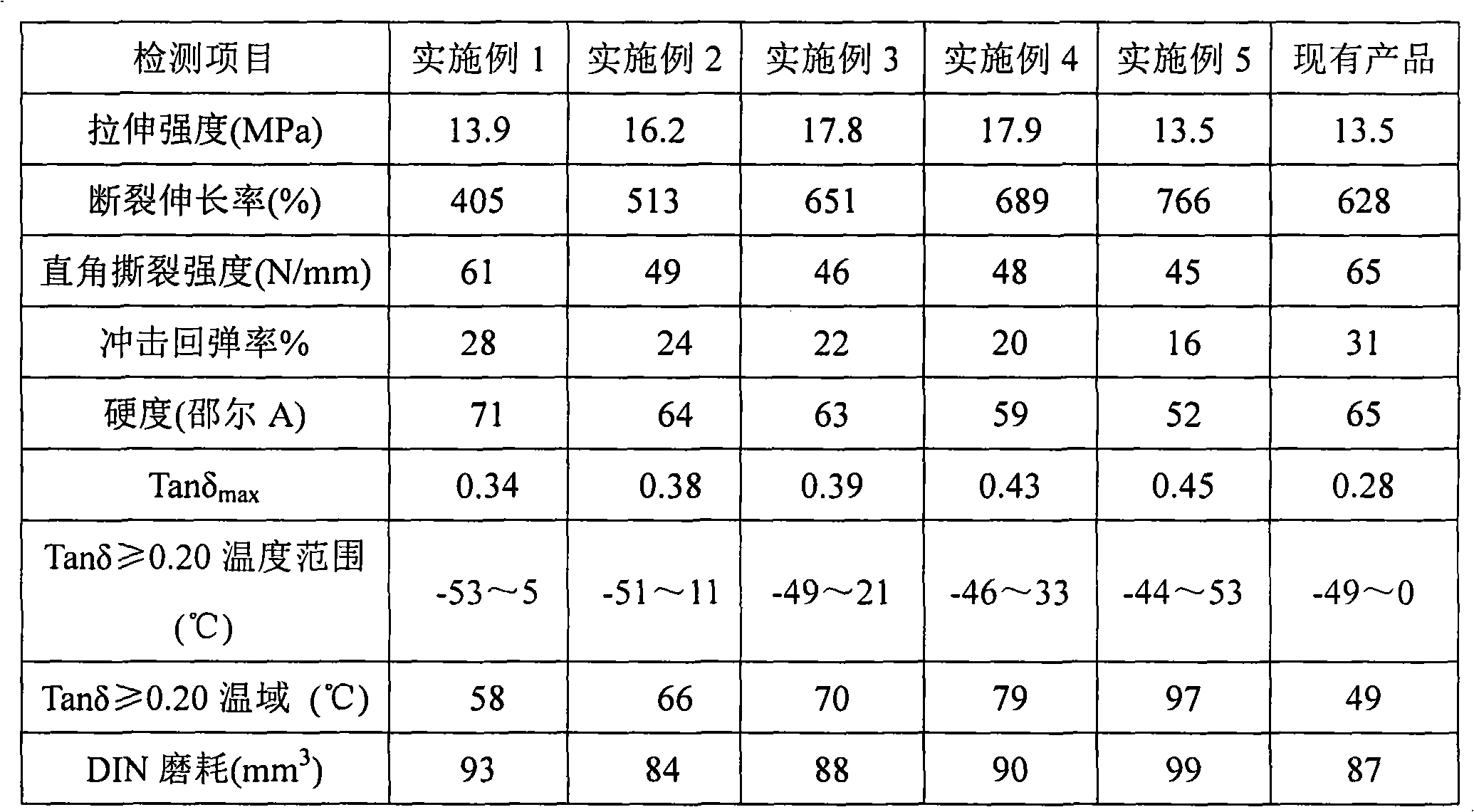

Examples

Embodiment 1

[0023] The composition (mass ratio) is: 30 parts of BIIR, 70 parts of BR, 50 parts of white carbon black, 3.0 parts of Si69, 5.0 parts of PEG, 5.0 parts of magnesium oxide, 3.0 parts of zinc oxide, 1.7 parts of stearic acid, 1.0 parts of DM, 0.3 parts of TMTM, 0.63 parts of NS, 1.5 parts of sulfur, and 1.0 parts of antioxidant 4010NA.

[0024] Weigh by above-mentioned proportioning, and carry out mixing according to the addition sequence described before and preparation technology, record the engineering vulcanization time (t) of mixed rubber through rotorless rheometer 90 ) at 150°C for 360s, then press molded at 150°C, and perform a performance test after parking for 24 hours.

Embodiment 2

[0026] The composition (mass ratio) is: 30 parts of BIIR, 70 parts of BR, 50 parts of white carbon black, 3.0 parts of Si69, 5.0 parts of PEG, 5.0 parts of magnesium oxide, 3.0 parts of zinc oxide, 1.7 parts of stearic acid, 1.0 parts of DM, 0.3 parts of TMTM, 0.63 parts of NS, 1.5 parts of sulfur, 1.0 parts of antioxidant 4010NA, 5.0 parts of C5 petroleum resin.

[0027] Weigh by above-mentioned proportioning, and carry out mixing according to the addition sequence described before and preparation technology, record the engineering vulcanization time (t) of mixed rubber through rotorless rheometer 90 ) at 150°C for 348s, then press molded at 150°C, and perform a performance test after parking for 24 hours.

Embodiment 3

[0029] The composition (mass ratio) is: 30 parts of BIIR, 70 parts of BR, 50 parts of white carbon black, 3.0 parts of Si69, 5.0 parts of PEG, 5.0 parts of magnesium oxide, 3.0 parts of zinc oxide, 1.7 parts of stearic acid, 1.0 parts of DM, 0.3 parts of TMTM, 0.63 parts of NS, 1.5 parts of sulfur, 1.0 parts of antioxidant 4010NA, 10.0 parts of C5 petroleum resin.

[0030] Weigh by above-mentioned proportioning, and carry out mixing according to the addition sequence described before and preparation technology, record the engineering vulcanization time (t) of mixed rubber through rotorless rheometer 90 ) at 150°C for 360s, then press molded at 150°C, and perform a performance test after parking for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com