Internal-combustion heating rotary vane type biomass gasification furnace

A biomass and gasifier technology, applied in indirect heating dry distillation, coke oven, special form dry distillation, etc. The temperature of the gasifier is not high enough to achieve the effect of improving the biomass gasification efficiency and gas calorific value, improving the biomass gasification efficiency, and being beneficial to heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

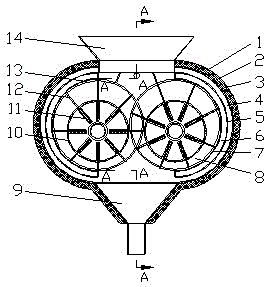

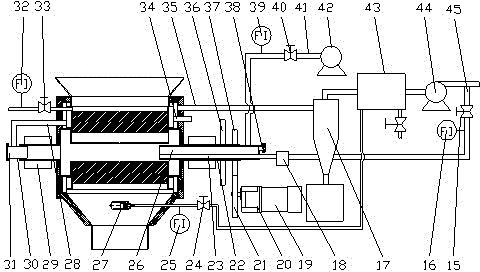

[0024] see figure 1 and figure 2 , a quasi-elliptical cylindrical furnace body 1 is adopted, the furnace body 1 is arranged axially and horizontally, the side wall of the furnace body 1 is set as a jacket structure, and the jacket is sequentially composed of gasification layer 8, gasification layer wall 7, Hot waste gas layer 6, hot waste gas layer wall 5, gas layer 4, gas layer wall 3 and insulation layer 2; track 13 is set on gasification layer wall 7; two horizontal internal combustion rotating pipes 10 are set in body of furnace 1, Inside the internal combustion rotary pipe 10, a plurality of slit plates 11 are arranged alternately along the circumference of its wall. The slits of the slit plates 11 are not connected to the interior of the internal combustion rotary pipe 10. Blades 12 are arranged in the gaps of the slit plates 11, and the blades 12 protrude The two ends of each internal combustion rotary pipe 10 are concentrically connected to two rotary support pipes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com