Internal combustion heating rotary vane biomass pyrolysis liquefaction device

A biomass pyrolysis and liquefaction device technology, applied in the field of pyrolysis and liquefaction devices, can solve the problems of complex material pretreatment, strict requirements on feed particle size, and strict requirements on types, so as to improve the efficiency of biomass liquefaction and pyrolysis Effect of liquefaction strength and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

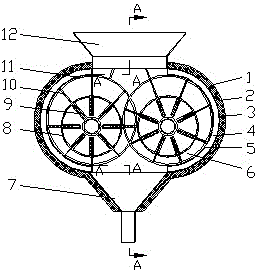

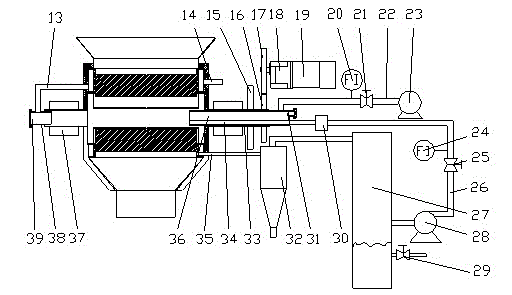

[0024] see figure 1 and figure 2 , using a quasi-elliptical cylindrical reactor 1, the reactor 1 is arranged axially and horizontally, the side wall of the reactor 1 is set as a jacket structure, and the jacket is sequentially composed of pyrolysis layer 6, pyrolysis layer wall 5, Hot waste gas layer 4, hot waste gas layer wall 3 and insulation layer 2; track 11 is set on pyrolysis layer wall 5; two horizontal internal combustion rotary pipes 8 are set at the same height below the center plane of reactor 1, and two internal combustion rotary pipes 8, a plurality of slit plates 9 are arranged alternately along the circumference of its wall. The slits of the slit plates 9 are not connected to the inside of the internal combustion rotating pipe 8. Blades 10 are arranged in the gaps of the slit plates 9, and the extended ends of the blades 10 are connected to the track 11 connections; the two ends of each internal combustion rotating pipe 8 are concentrically connected to two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com