Optimized control method of servo motor based on servo tool rest controller

A technology of servo tool holder and servo motor, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of not being able to improve the efficiency of tool changing to the greatest extent, occupying additional system resources, and reducing the impact of mechanical start-stop, etc. Achieve the effect of improving the utilization rate and service life, ensuring the efficiency of tool change, and reducing the impact of mechanical start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

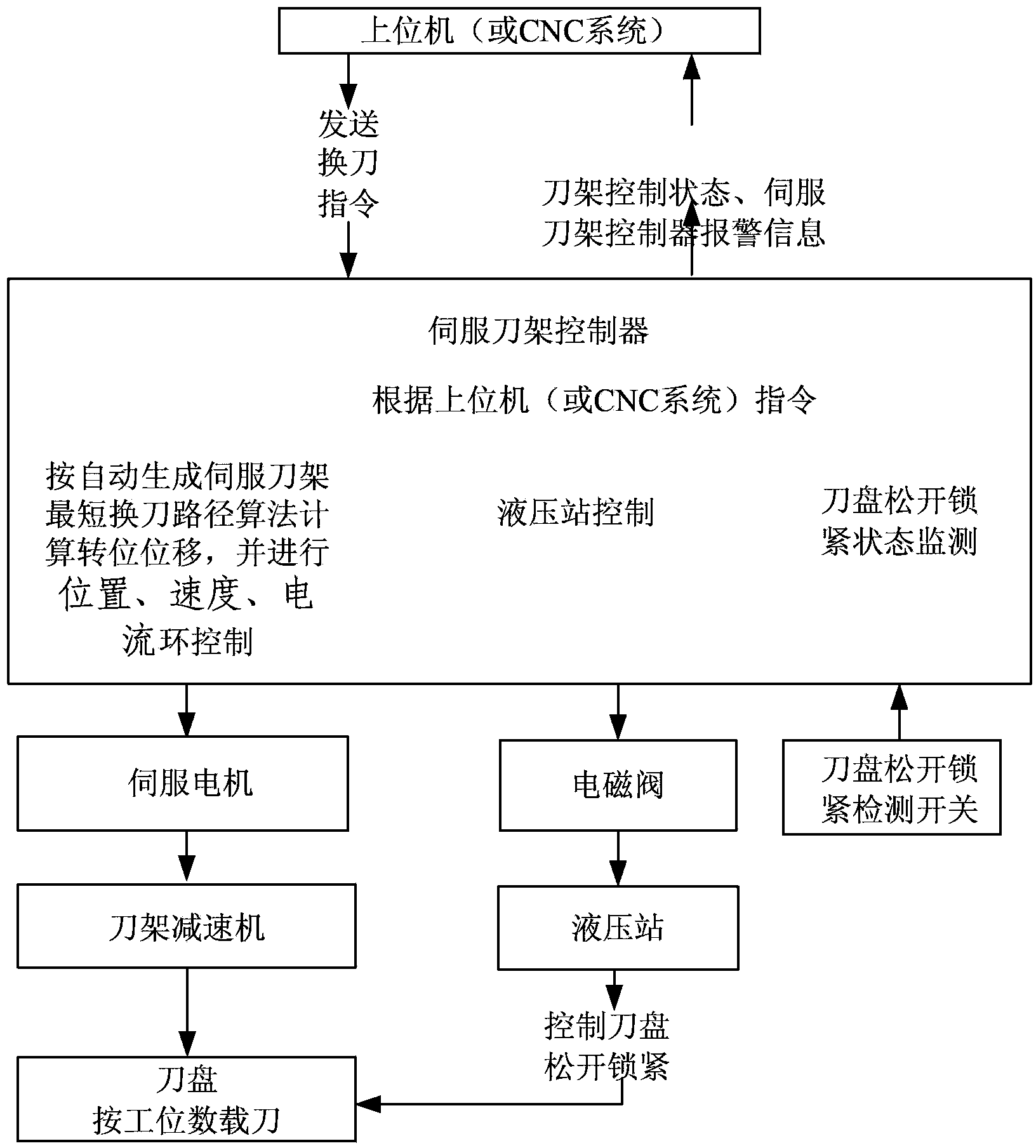

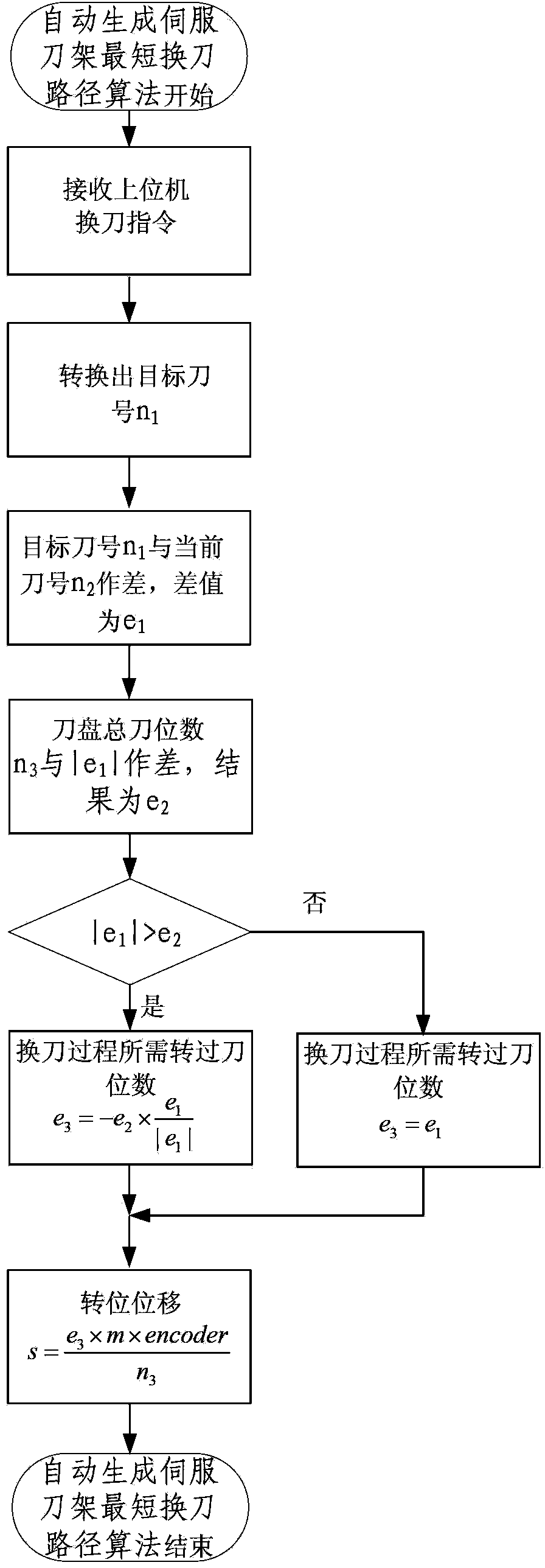

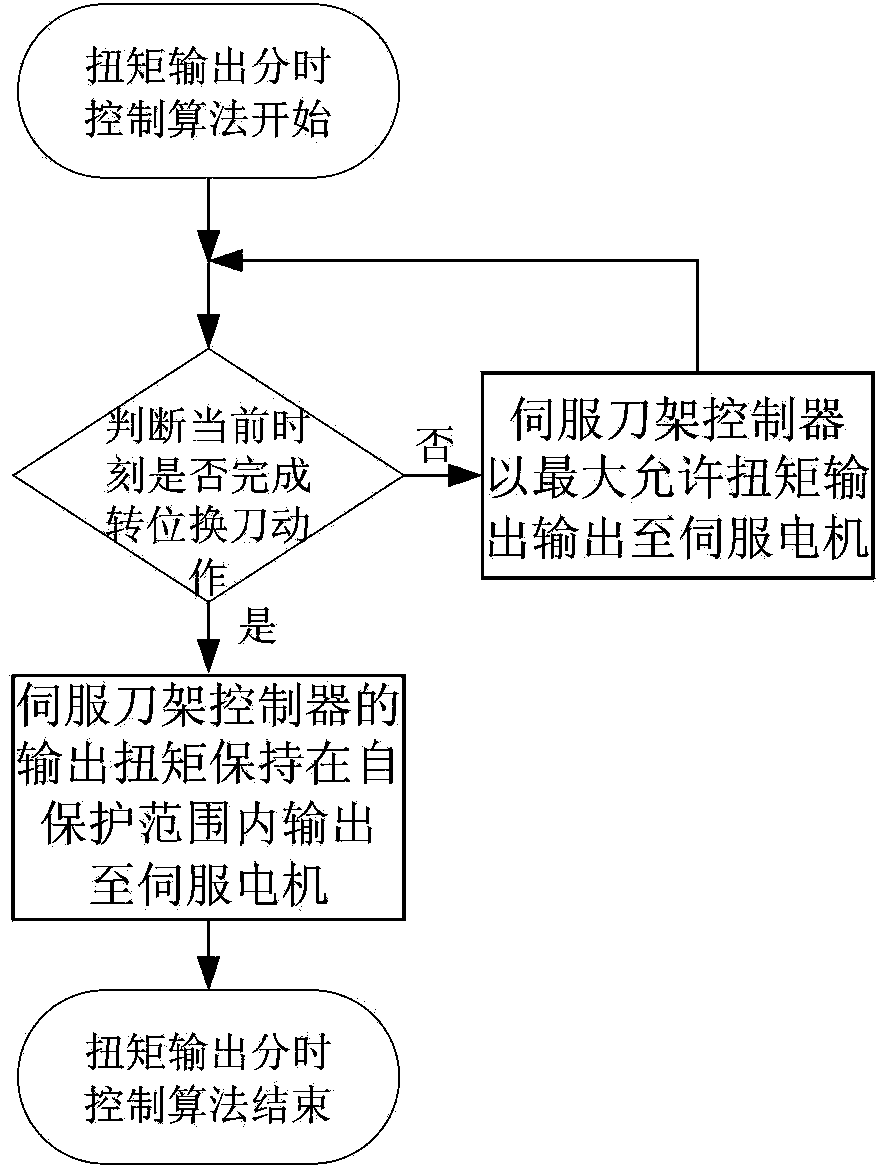

[0037] The present invention provides an optimal control algorithm for a servo motor based on a servo tool post controller, which mainly includes three parts: (1) Automatically generate the algorithm for the shortest tool change path of the servo tool post, that is, when the servo tool post controller receives the After the upper computer tool change command, convert it into the target tool number, and calculate the indexing displacement of the servo motor according to the principle of the shortest indexing path according to the reduction ratio of the pre-configured servo tool post reducer and the line number of the servo motor encoder ;(2) Torque output time-sharing control algorithm, that is, in the state of indexing and tool changing action, the servo tool holder controller outputs the maximum allowable torque output to the servo motor to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com