Straight hole ceramic filter used for cast steel and high temperature alloy

A technology of ceramic filter and high-temperature alloy, which is applied in the field of industrial ceramics and silicate materials, can solve the problems of large filtering area, limited application, complicated manufacturing process, etc., and achieve good thermal shock resistance and good filtering function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

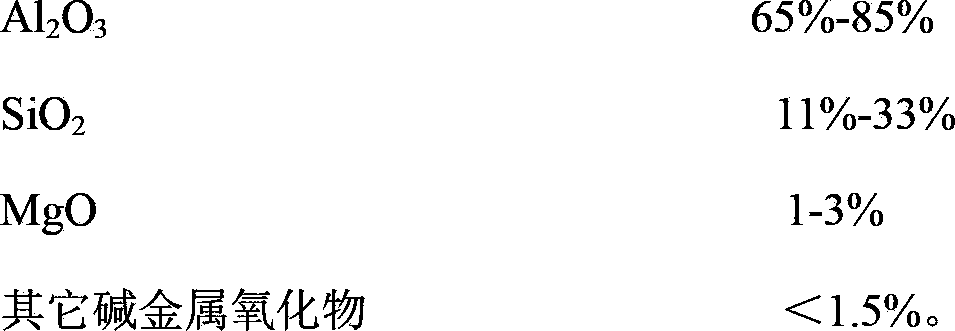

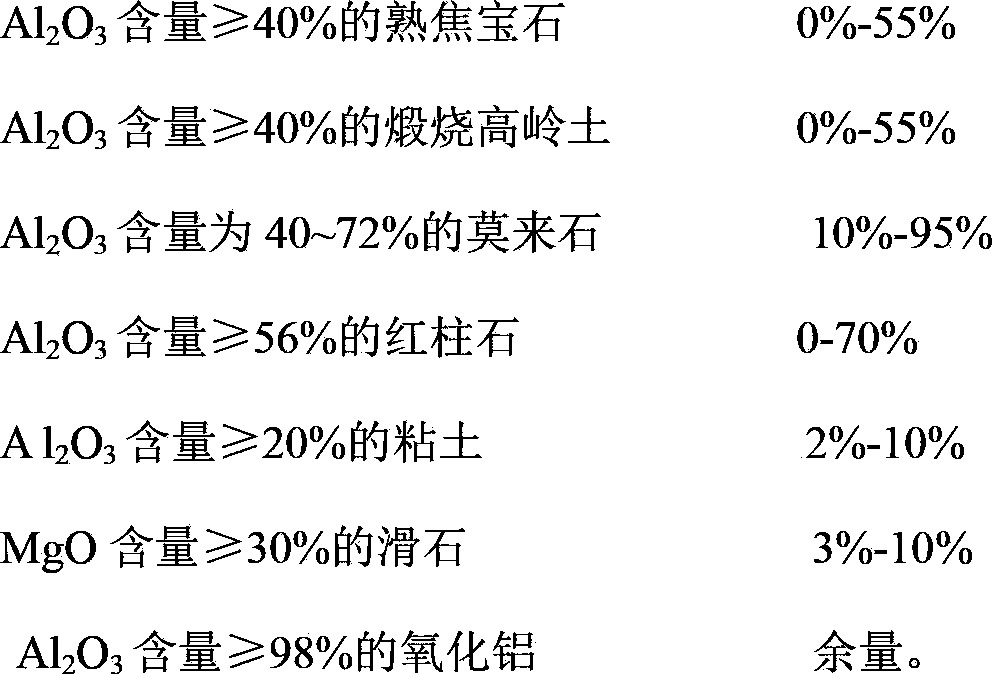

Method used

Image

Examples

Embodiment 1

[0041] The straight hole ceramic filter is 75mm*75mm*20mm in size, the hole type is 2.5mm*2.5mm square hole, and the rib thickness is 0.7mm. The weight ratio of cooked coke gems (particle size less than 200 mesh), alumina (particle size less than 325 mesh), clay (particle size less than 500 mesh) and talc (particle size less than 500 mesh) after ball milling and sieving is 50: The raw materials of 45:3:2 were mixed into 200Kg, plus 6% hydroxypropyl methylcellulose of the raw material weight, ball milled for 2 hours, after passing through a 100 mesh sieve, adding 20% water of the total weight of raw materials, 3% tung oil and 3 % rapeseed oil, kneaded in a kneader for 20 minutes, aged for 18-24 hours after being muddled three times by a mud trainer, and the aged mud was extruded from the corresponding mold of the above-mentioned filter after being muddled in a vacuum. After being shaped by a box-type microwave oven, the extruded body is dried with circulating warm air in a bo...

Embodiment 2

[0043] The size of the straight hole ceramic filter is 100mm*60mm*20mm, the hole type is a hexagonal hole with an inscribed circle diameter of Φ2.5mm, and the rib thickness is 0.8mm. Calcined kaolin (particle size less than 200 mesh), alumina (particle size less than 300 mesh), clay (particle size less than 500 mesh) and talc (particle size less than 500 mesh) with a weight ratio of 35:60:2:3 Mix the raw materials into 200Kg, add 6% hydroxypropyl methylcellulose of the raw material weight, ball mill for 2 hours, pass through a 100-mesh sieve, add 18% water and 6% high-quality soybean oil of the total weight of the raw materials, and knead in a kneader After 20 minutes, after 3 times of mud refining by the mud refining machine, it will be aged for 18-24 hours. After the aged mud is subjected to vacuum refining, it will be extruded by the corresponding mold of the above-mentioned filter. After the extruded body is shaped by a box-type microwave oven, it is dried with circulating...

Embodiment 3

[0045] The straight hole ceramic filter is 100mm*100mm*25mm, the hole type is 3.8mm round hole, and the rib thickness is 0.8mm. Use super-grade boiled gemstones (particle size less than 200 mesh), calcined kaolin (particle size less than 200 mesh), alumina (particle size less than 300 mesh), clay (particle size less than 500 mesh), talc (particle size less than 500 mesh) , andalusite (particle size less than 500 mesh) raw materials with a weight ratio of 15:15:60:2:3:5 are mixed into 200Kg, plus 6% hydroxypropyl methylcellulose of raw material weight, ball milled for 2 hours, passed After a 100-mesh sieve, add 18% water and 6% hydraulic oil of the total weight of the raw materials, and knead in a kneader for 20 minutes. After 3 times of mud refining, it will be stale for 18-24 hours. The stale mud will be vacuum-trained After mud, select the corresponding mold of the above-mentioned filter to extrude. After being shaped by a box-type microwave oven, the extruded body is dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com