Catalytic cracking coupling process for preparing low-carbon olefin and C<5+> hydrocarbon by using organic oxygen-containing compound

A low-carbon olefin, catalytic cracking technology, applied in the field of organic oxygen-containing compound to low-carbon olefin process, organic oxygen-containing compound to low-carbon olefin system field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

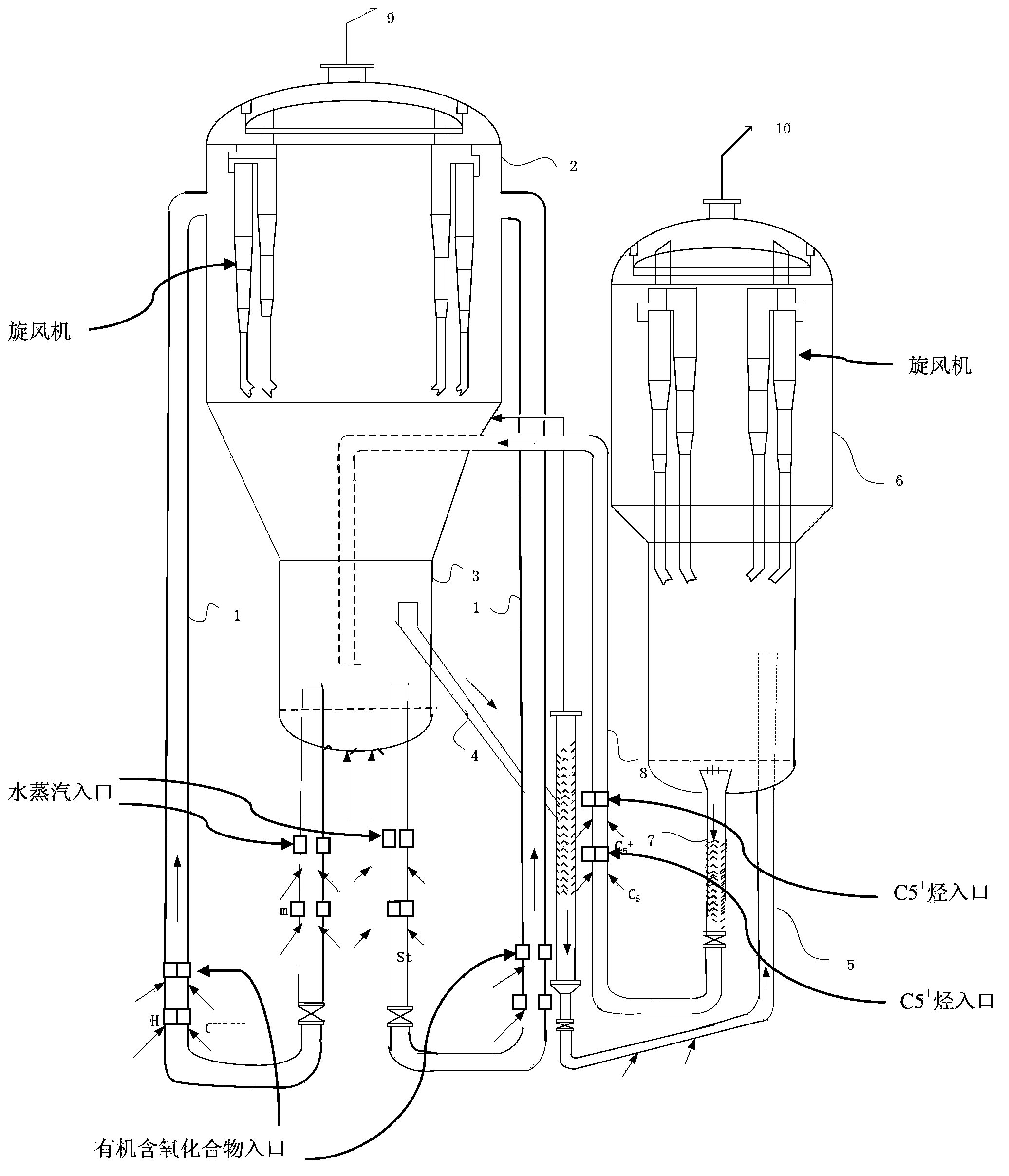

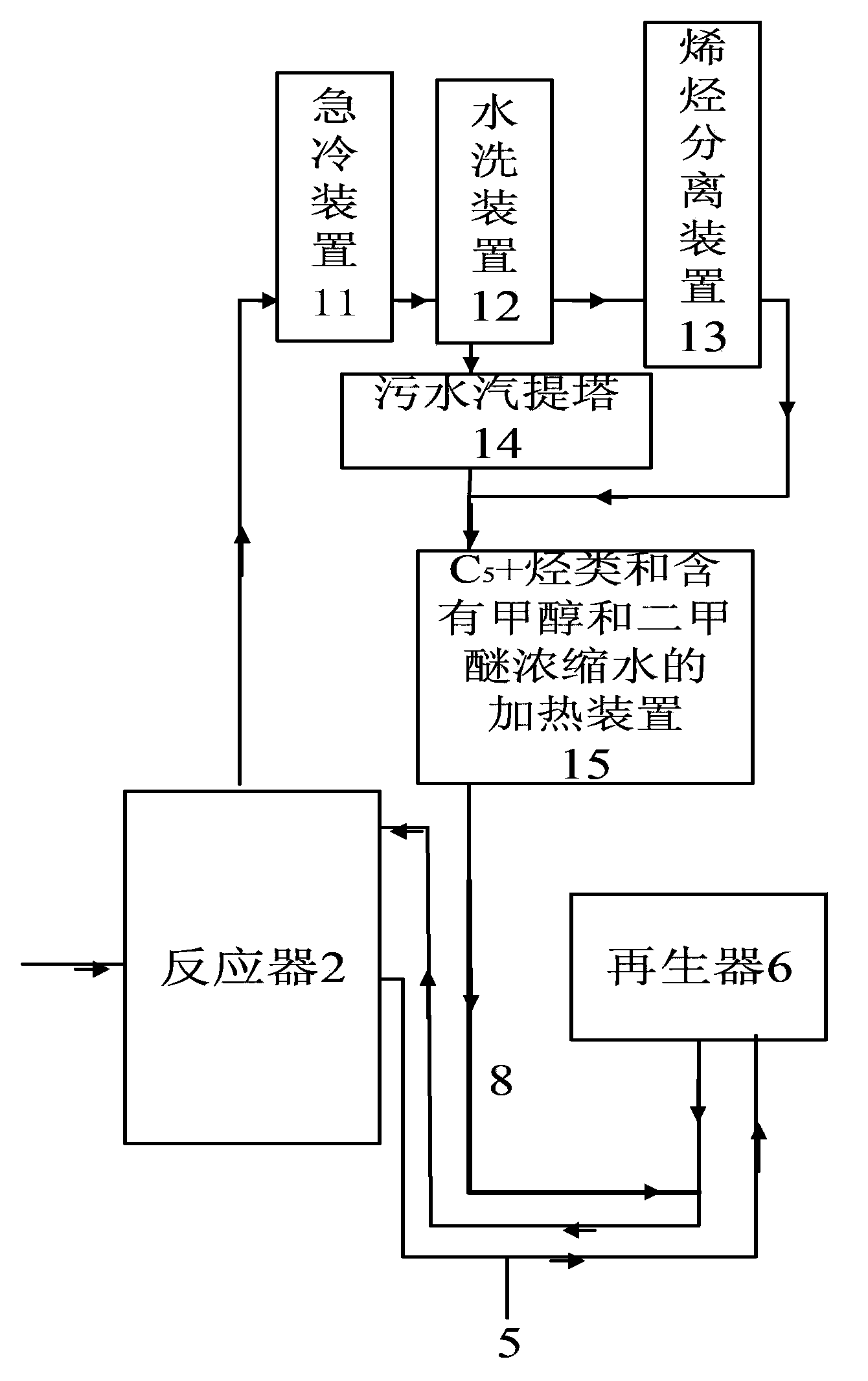

[0064] use figure 1 The organic oxygenated compounds shown in the preparation of light olefins with C 5+ Hydrocarbon catalytic cracking coupling system prepares light olefins from methanol, wherein, using the system product gas through figure 2 The process shown in the resulting C 5+ The mixture of hydrocarbon by-products and concentrated sewage containing methanol and dimethyl ether is used as C in this embodiment 1 5+ hydrocarbon feedstock, the C 5+ Hydrocarbon feedstock such as figure 2 Shown is vaporized and heated to around 350°C.

[0065] Set 4 C's on Regenerated Catalyst Delivery Piping 5+ Hydrocarbon inlets, 4 inlets are staggered and arranged oppositely, by controlling the circulation flow of the regenerated catalyst and C 5+ The amount of hydrocarbon injected, so that the regenerated catalyst and C 5+ The weight ratio of hydrocarbons in the regenerated catalyst delivery pipeline is controlled between 0.05-0.15, so that their contact reaction time in the rege...

Embodiment 2

[0068] In addition to changing the process parameters, the experimental process of Example 1 was repeated, and the process parameters and final experimental results used in Example 2 are also shown in Table 1 and Table 2 below.

Embodiment 3

[0070] In addition to changing the process parameters, the experimental process of Example 1 was repeated, and the process parameters used in Example 3 and the final experimental results thereof are also shown in Table 1 and Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com