Preparation method of poly (butylene succinate) (PBS) used as spinning dope

A technology of polybutylene succinate and spinning dope is applied in the preparation of polybutylene succinate polymer and the preparation field of polybutylene succinate, and can solve the problem of excessive molecular weight distribution , polymerization degree difference, uneven distribution and other problems, to achieve the effect of low linear density uneven rate, small linear density deviation, and low molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

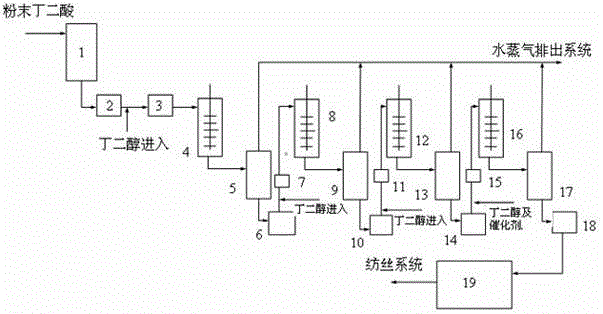

[0034] The PBS stock solution used for spinning was prepared using the polymerization form of the continuous quaternary reaction. The addition amount of succinic acid is 10kg / h.

[0035] A method for preparing polybutylene succinate used as a spinning stock solution, using succinic acid and butanediol with a mass ratio of 1:0.8~1.2 to realize PBS bulk polymerization through a four-stage reaction, and prepare it for spinning Stock solution of polybutylene succinate;

[0036] Specific steps are as follows:

[0037] (1) First-stage reaction: Add the succinic acid to be reacted into the electrically heated material melter 1 at a flow rate of 10kg / h, heat it to 180°C, and transport it to the first dynamic mixer 3 through the first conveying device 2 , add 4.74kg / h of butanediol during the conveying process, fully mix in the first dynamic mixer 3; continue to convey to the first-stage main reactor 4, control the reaction temperature to 180°C, and the reaction pressure to 0.4MPa ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com