Method for preparing chemically crosslinked photonic crystal hydrogel with adjustable color

A chemical cross-linking, photonic crystal technology, applied in the field of photonic crystal hydrogel preparation, can solve problems such as poor mechanical strength of nanogels, and achieve the effects of weak mechanical strength, low cost, and temperature responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of colloidal crystal hydrogel solution:

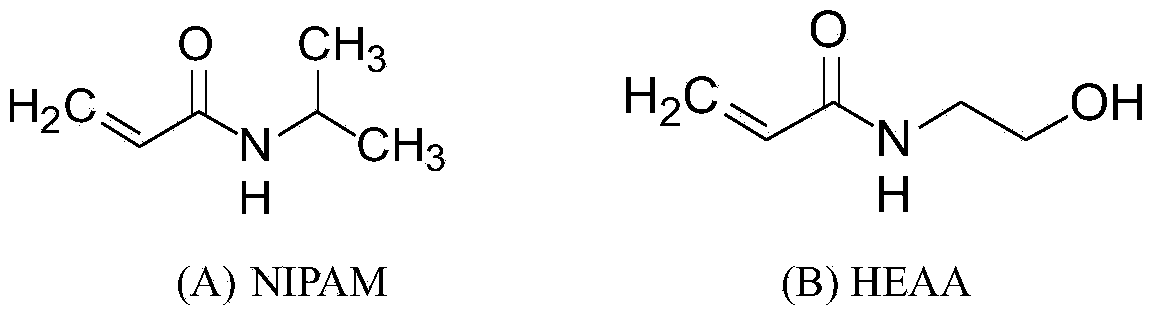

[0027] (1) Dissolve 3.7903g of NIPAM, 0.3808g of HEAA, 0.0725g of N,N'-methylenebisacrylamide and 0.1095g of sodium lauryl sulfate in 250g of deionized water, blow N2 at room temperature to remove oxygen, and magnetically stir 120 minutes;

[0028] (2) The reaction temperature was raised to 70°C and kept for 40 minutes under the protection of N2;

[0029] (3) Add 0.17g of ammonium persulfate to the above solution, keep the N2 atmosphere, and continue to react for 4 hours;

[0030] (4) Then soak the obtained reactants in deionized water and dialyze for 7 days, change the water once a day to remove the residual reaction raw materials and electrolytes in the reaction system. The molecular weight cut-off of the dialysis bag used is 8000-14000. Instantly.

[0031] 2. Curing treatment of colloidal crystal hydrogel:

[0032] Put the obtained colloidal crystal hydrogel solution in an oven to heat and concentrate, adj...

Embodiment 2

[0034] 1. Preparation of colloidal crystal hydrogel solution:

[0035] (1) Dissolve 3.7903g of NIPAM, 0.3808g of HEAA, 0.0725g of N,N'-methylenebisacrylamide and 0.1095g of sodium lauryl sulfate in 250g of deionized water, blow N2 at room temperature to remove oxygen, and magnetically stir 120 minutes;

[0036] (2) The reaction temperature was raised to 70°C and kept for 40 minutes under the protection of N2;

[0037] (3) Add 0.17g of ammonium persulfate to the above solution, keep the N2 atmosphere, and continue to react for 4 hours;

[0038] (4) Then soak the obtained reactants in deionized water and dialyze for 7 days, change the water once a day to remove the residual reaction raw materials and electrolytes in the reaction system. The molecular weight cut-off of the dialysis bag used is 8000-14000. Instantly.

[0039] 2. Curing treatment of colloidal crystal hydrogel:

[0040] Put the obtained colloidal crystal hydrogel solution into an oven to heat and concentrate, a...

Embodiment 3

[0042] 1. Preparation of colloidal crystal hydrogel solution:

[0043](1) Dissolve 3.7864g NIPAM, 0.3960g HEAA, 0.0701g N,N'-methylenebisacrylamide and 0.0505g sodium lauryl sulfate in 250g deionized water, blow N2 at room temperature to remove oxygen, and magnetically stir 120 minutes;

[0044] (2) The reaction temperature was raised to 70°C and kept for 40 minutes under the protection of N2;

[0045] (3) Add 0.17g of ammonium persulfate to the above solution, keep the N2 atmosphere, and continue to react for 4 hours;

[0046] (4) Then soak the obtained reactants in deionized water and dialyze for 7 days, change the water once a day to remove the residual reaction raw materials and electrolytes in the reaction system. The molecular weight cut-off of the dialysis bag used is 8000-14000. Instantly.

[0047] 2. Curing treatment of colloidal crystal hydrogel:

[0048] Put the obtained colloidal crystal hydrogel solution in an oven to heat and concentrate, adjust its concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com