Method for manufacturing separator and electro-chemical device equipped with separator manufactured thereby

一种制造方法、隔膜的技术,应用在最终产品制造、二次电池制造、可持续制造/加工等方向,达到防止电池性能的劣化、抑制损失、小化孔堵塞的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

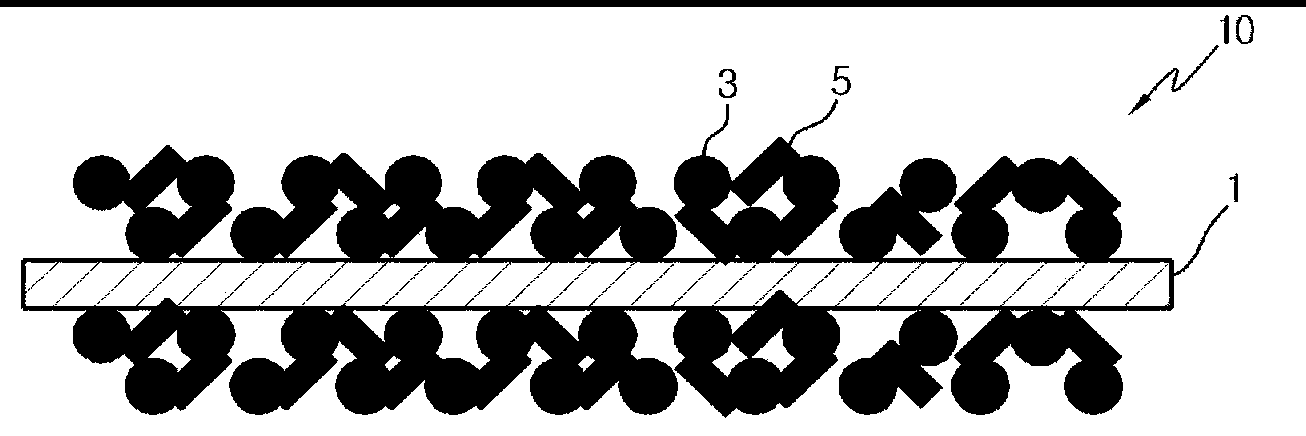

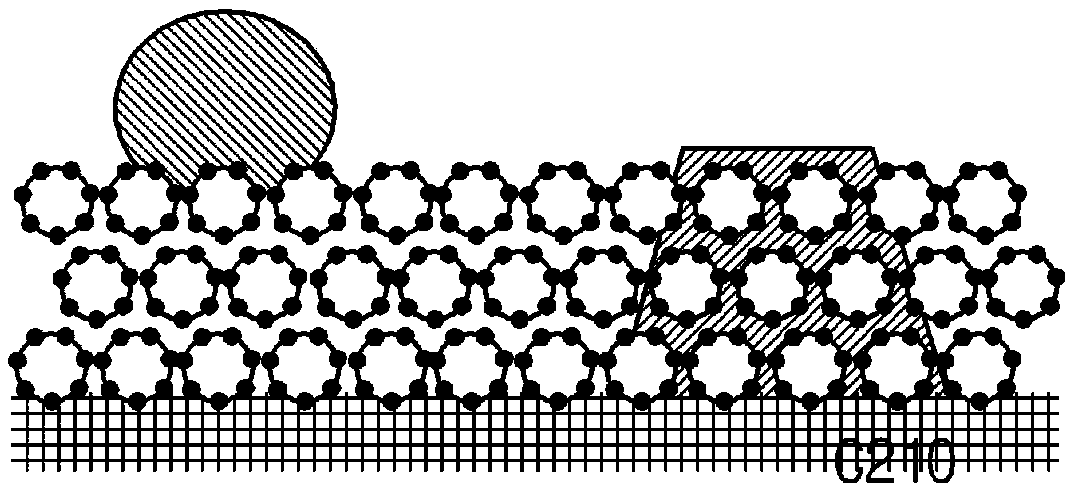

Embodiment 1

[0091] Polyvinylidene fluoride-co-hexafluoropropylene (PVdF-HFP) copolymer was added as a polymer in an amount of 5% by weight to acetone, and dissolved at 50°C for about 12 hours or more to prepare an adhesive agent polymer solution. Will Al 2 o 3 The powder was added to the prepared binder polymer solution so that the binder polymer and Al 2 o 3 The weight ratio of the powder is 10:90, and the Al 2 o 3 The powder was pulverized by a ball mill and dispersed for 12 hours or more to prepare a slurry. Al present in the slurry thus prepared 2 o 3 The particle size is about 400nm. The slurry was coated on a porous polyethylene film having a thickness of 12 μm and a porosity of 45% by dip coating, and the coating thickness was controlled to a thickness of about 20 μm.

[0092] The pore diameter and porosity of the porous coating layer formed on the porous polyethylene film were measured by a porosimeter. As a result, the pore diameter and porosity of the porous coating lay...

Embodiment 2

[0100] The procedure of Example 1 was repeated except that a binder solution obtained by dissolving 10 parts by weight of polyvinylpyrrolidone (Aldrich, Mw: 55,000) in 100 parts by weight of water was used to prepare a separator.

[0101] In the separator, the contact angle of the binder solution with the porous coating was maintained at 85° for 30 seconds.

Embodiment 3

[0103] The procedure of Example 1 was repeated except that a binder solution obtained by dissolving 10 parts by weight of polyethylene glycol (Aldrich, Mw: 8,000) in 100 parts by weight of water was used to prepare a separator.

[0104] In the separator, the contact angle of the binder solution with the surface of the porous coating was maintained at 93° for 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com