Bacteriostatic Huanglian-nanometer zinc oxide ultrafine glass fiber air filter material

A technology of ultra-fine glass fiber and air filter materials, which is applied in the fields of filtration and separation, chemical instruments and methods, deodorization, etc., and can solve problems such as easy blockage, secondary pollution, and large wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

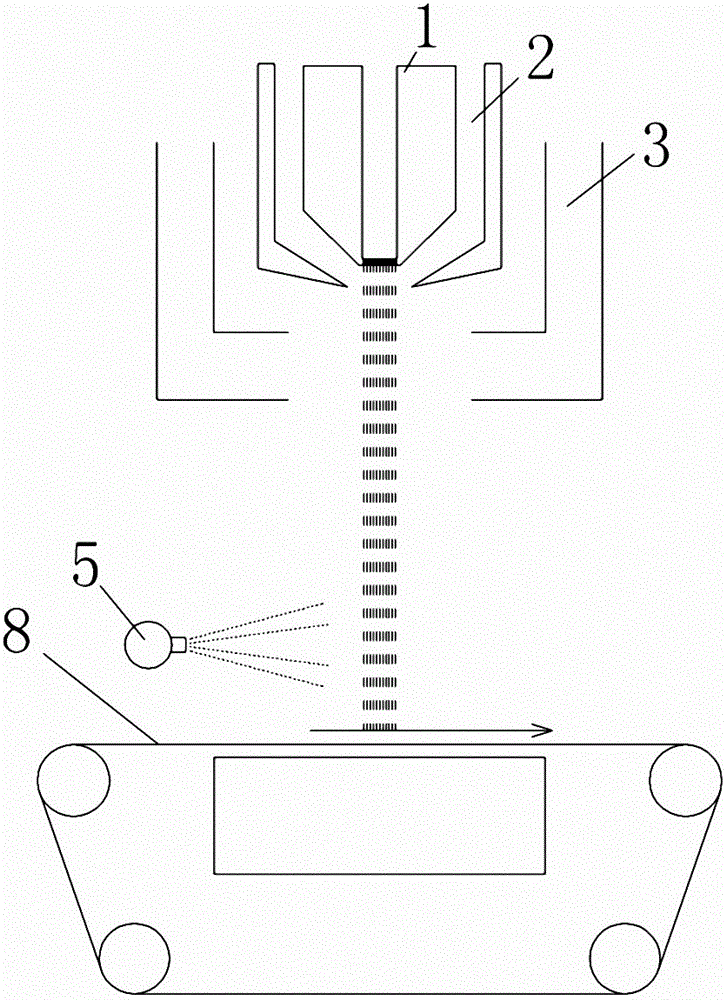

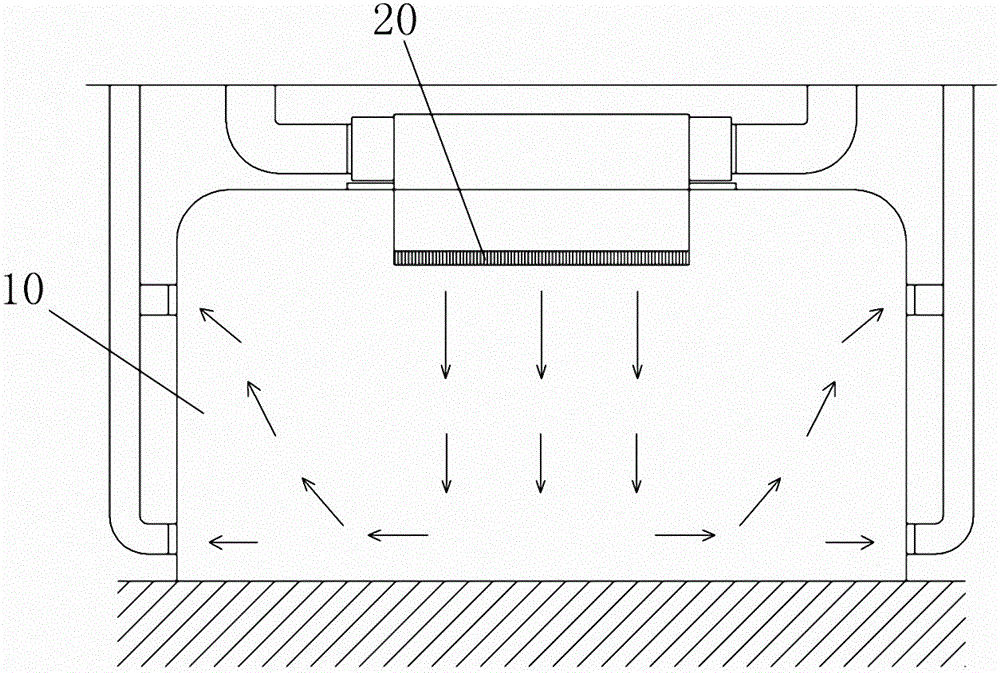

[0015] Please refer to figure 1 and figure 2 Shown, be a kind of specific embodiment of the bacteriostatic Huanglian-nanometer zinc oxide ultrafine glass fiber air filter material of the present invention, this bacteriostatic Huanglian-nanometer zinc oxide ultrafine glass fiber air filter material, will Huanglian extract, xanthan gum, zinc oxide nanoparticles and glass fiber are mixed according to the weight ratio of 0.4:0.0006:0.0001:1, and melt-blown weaving is carried out using melt-blown equipment and technology to form an ultra-fine glass fiber filter material.

[0016] The preparation steps of the described Huanglian extract are as follows: take 20 grams of Chinese medicine Huanglian decoction pieces, add 500ml of water, boil, concentrate and filter to obtain 200ml of concentrated filtrate, air-dry and stand at 90°C to obtain solid Huanglian precipitation, after Made into fine powder particles after drying;

[0017] The preparation steps of the nano-zinc oxide particl...

Embodiment 1

[0023] 1, preparation of Huanglian extract: get 800 grams of Chinese medicine Huanglian decoction pieces, add 20000ml of water, boil, concentrate and filter to obtain 8000ml of filtrate after concentration, air-dry and leave standstill to obtain solid Huanglian precipitation under 90 ° C conditions, after drying, prepare into fine powder particles 400 grams.

[0024] 2. Preparation of water-soluble zinc oxide nanoparticles:

[0025] 2. Mix 0.1 g of zinc oxide with 55°C deionized water at a weight percentage of 1:8, and stir evenly to make a zinc oxide solution; pass CO into the zinc oxide solution2 Gas, while stirring and heating to 90 ° C, keep warm for 5 hours, and then stop feeding CO 2 Gas and heating; after the reacted solution is filtered out of water, the resultant is dried at a temperature below 200°C, and the dried residue is crushed; after the crushed powder is placed in an environment of 300°C, it is roasted Obtain 0.1 g of nanometer zinc oxide powder.

[0026] Pl...

Embodiment 2

[0028] 1. Preparation of Huanglian extract: take 1000 grams of Chinese medicine Huanglian decoction pieces, add 25000ml of water, boil, concentrate and filter to obtain 10000ml of filtrate after concentration, air-dry and leave standstill to obtain solid Huanglian precipitation under 90°C, after drying, prepare into fine powder particles 400 grams.

[0029] 2. Preparation of water-soluble zinc oxide nanoparticles:

[0030] 2. Mix 0.1 g of zinc oxide with 55°C deionized water at a weight percentage of 1:8, and stir evenly to make a zinc oxide solution; pass CO into the zinc oxide solution 2 Gas, while stirring and heating to 90 ° C, keep warm for 5 hours, and then stop feeding CO 2 Gas and heating; after the reacted solution is filtered out of water, the resultant is dried at a temperature below 200°C, and the dried residue is crushed; after the crushed powder is placed in an environment of 300°C, it is roasted Obtain 0.1 g of nanometer zinc oxide powder.

[0031] Please ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com