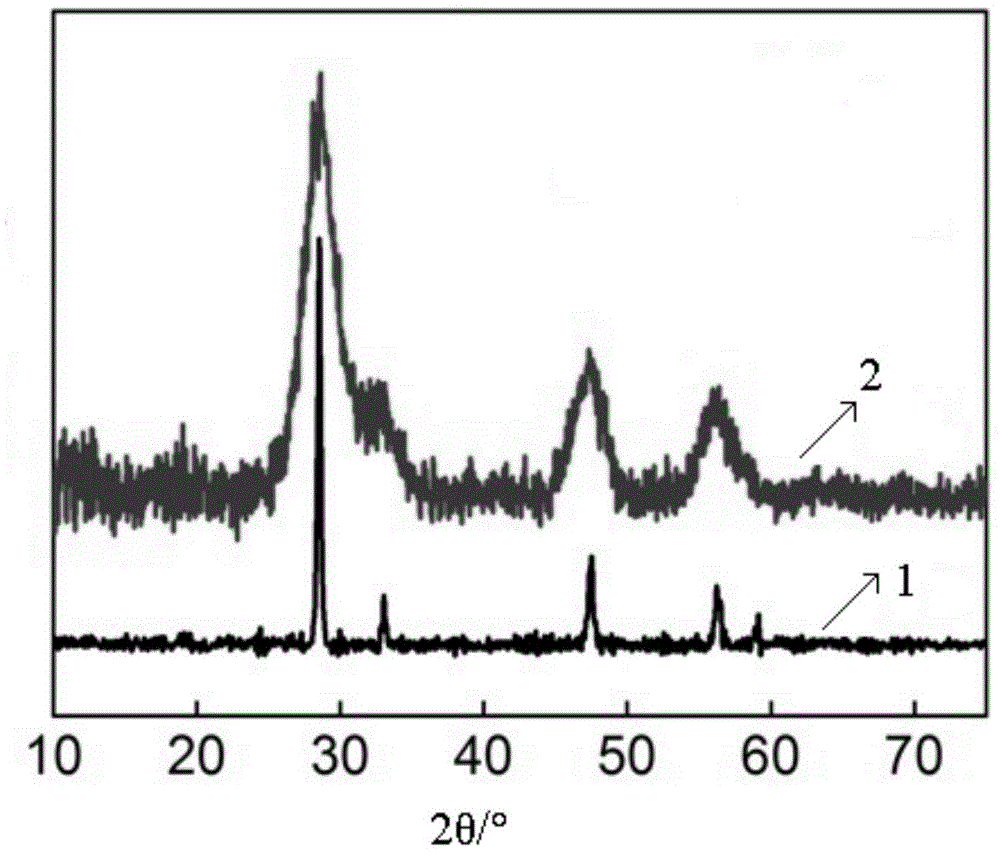

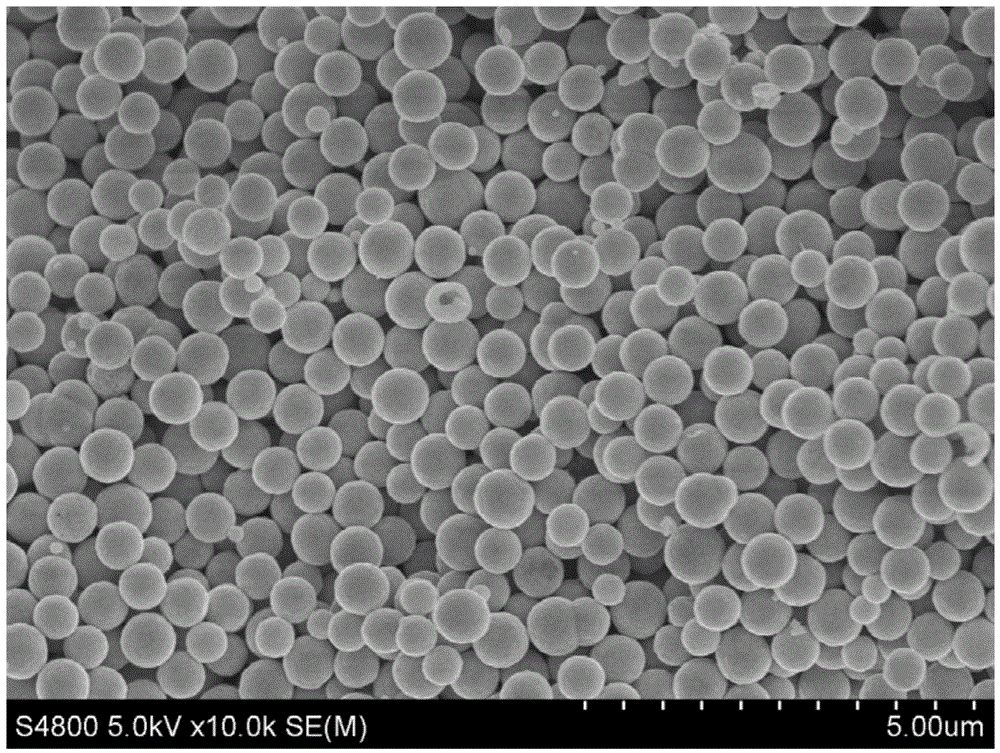

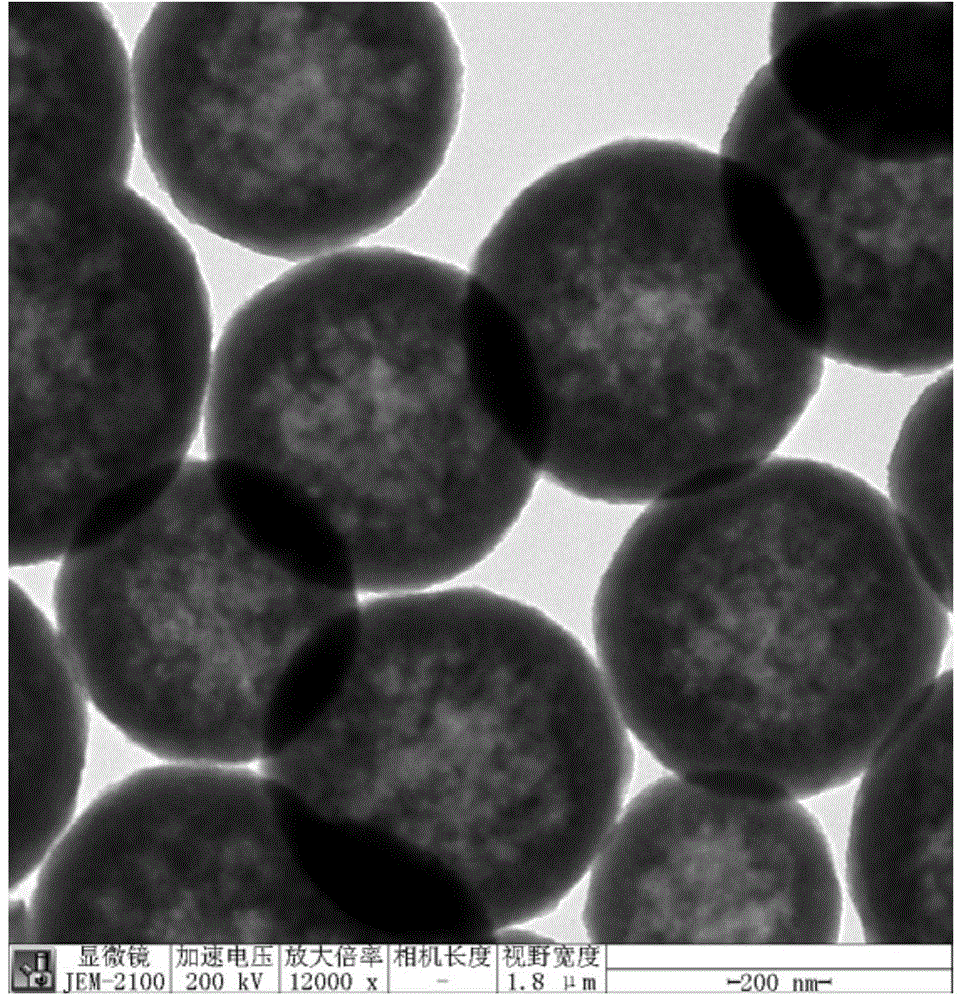

Preparation method of a sulfur-doped ceria mesoporous hollow sphere photocatalyst

A mesoporous hollow sphere, ceria technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic activity, small specific surface area, non-uniform pore size, etc. Achieve effective degradation, increase specific surface area, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Embodiment 1: This embodiment is a preparation method of sulfur-doped ceria mesoporous hollow sphere photocatalyst, which is specifically completed according to the following steps:

[0023] 1. Preparation of cerium source aqueous solution: dissolving cerium source in distilled water to obtain cerium source aqueous solution;

[0024] The mass of the cerium source described in step 1 and the volume ratio of distilled water are 1g:(160mL~170mL);

[0025] 2. Add sulfur source: add sulfur source to cerium source aqueous solution, stir until sulfur source is dissolved in cerium source aqueous solution, obtain cerium source / sulfur source aqueous solution;

[0026] The mass ratio of the mass of the cerium source in the aqueous solution of the cerium source described in step 2 to the mass ratio of the sulfur source is 1:(1.5~3);

[0027] 3. Adding a surfactant: adding a surfactant to the cerium source / sulfur source aqueous solution, stirring evenly to obtain a mixed solution; ...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the source of cerium in step 1 is cerium nitrate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the mass of the cerium source described in step 1 to the distilled water is 1g:(165mL-170mL). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com