Arc closing method for laser welding of superalloy

A technology of laser welding and high-temperature alloys, which is applied in the field of laser welding of alloys and laser welding of high-temperature alloys. It can solve the problems of dense arc-stop pores and arc craters, achieve excessively smooth welds, and ensure the internal quality and appearance of welds. Quality, the effect of ensuring the appearance quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Butt welding of 2mm thick plate of GH4169 superalloy material

[0043] Butt welding of GH4169 superalloy with a welded joint thickness of 2mm. During laser welding, the welding power P 焊 It is 1700W, the shielding gas is argon, the side blowing gas flow L is 8L / min, the back shielding gas flow L is 4L / min, the crater speed v is 1100mm / min, the crater pulse period is 20ms, and the crater welding length is 10mm; According to the formula, the number of arcing pulses is n=28; enter the arcing stage;

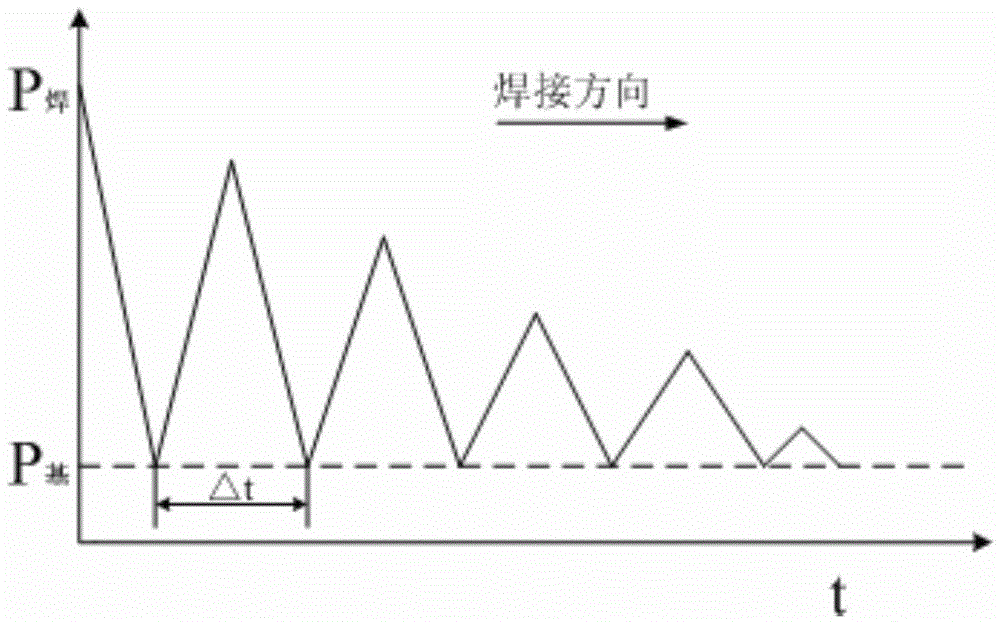

[0044] In the crater section 1, the laser scanning direction is forward, after 28 crater pulses, the output power of the crater welding laser attenuates from 1700W to the base value power of 50W within 560ms;

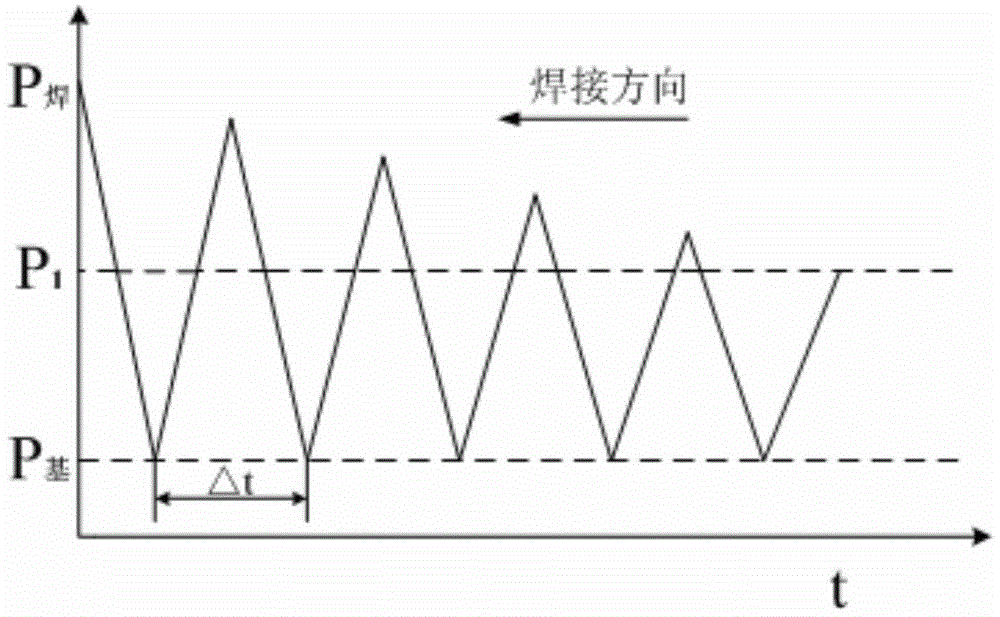

[0045] Entering the crater section 2, the laser scanning direction is reversed, and after 28 crater pulses, the output power of the crater welding laser oscillates from 1700W to a base value of 875W within 560ms;

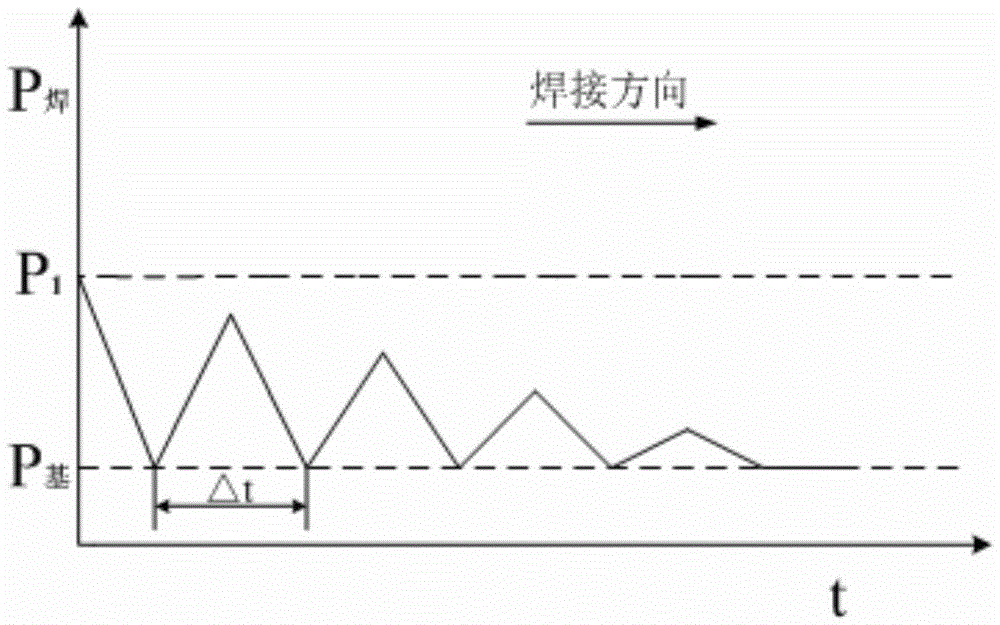

[0046] Entering the arc chopping section ...

Embodiment 2

[0049] Example 2: Butt welding of 3mm thick plate of Inconel601 superalloy material

[0050] Butt welding of GH4169 superalloy with a welded joint thickness of 2mm. During laser welding, the welding power P 焊 is 2300W, the shielding gas is argon, the side blowing gas flow L is 8L / min, the back shielding gas flow L is 5L / min, the crater speed v is 900mm / min, the crater pulse period is 10ms, and the crater length is 10mm; according to Formula, the number of arcing pulses n=67, enter the arcing stage;

[0051] In the crater section 1, the laser scanning direction is forward, after 67 crater pulses, the output power of the crater welding laser attenuates from 2300W to the base value power of 80W within 670ms;

[0052] Entering the crater section 2, the laser scanning direction is reversed. After 67 crater pulses, the output power of the crater welding laser oscillates from 2300W to a base value of 1190W within 670ms;

[0053] Entering the arc chopping section 3, the laser scann...

Embodiment 3

[0056] Example 3: Butt welding of 5mm thick plate of GH4169 superalloy material

[0057] Butt welding of GH4169 superalloy with a welded joint thickness of 5mm. During laser welding, the welding power P 焊 is 3300W, the shielding gas is argon, the side blowing gas flow L is 10L / min, the back shielding gas flow L is 8L / min, the crater speed v is 700mm / min, the crater pulse period is 20ms, and the crater length is 10mm; according to Formula, the number of arcing pulses n=43, enter the arcing stage;

[0058] In the crater section 1, the laser scanning direction is forward, after 43 crater pulses, the output power of the crater welding laser attenuates from 3300W to the base value power of 100W within 860ms;

[0059] Entering the crater section 2, the laser scanning direction is reversed, and after 43 crater pulses, the output power of the crater welding laser oscillates from 3300W to a base value of 1700W within 860ms;

[0060] Entering the arc chopping section 3, the laser sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com