Method and device for triple-corresponding positioning compounding of anti-counterfeit printing

A technology of anti-counterfeiting printing and compound equipment, which is applied in the field of anti-counterfeiting, can solve the problems of slow hot stamping and covering ink printing, high equipment cost, and high substrate consumption, so as to save labor, save consumables, and solve bottleneck problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

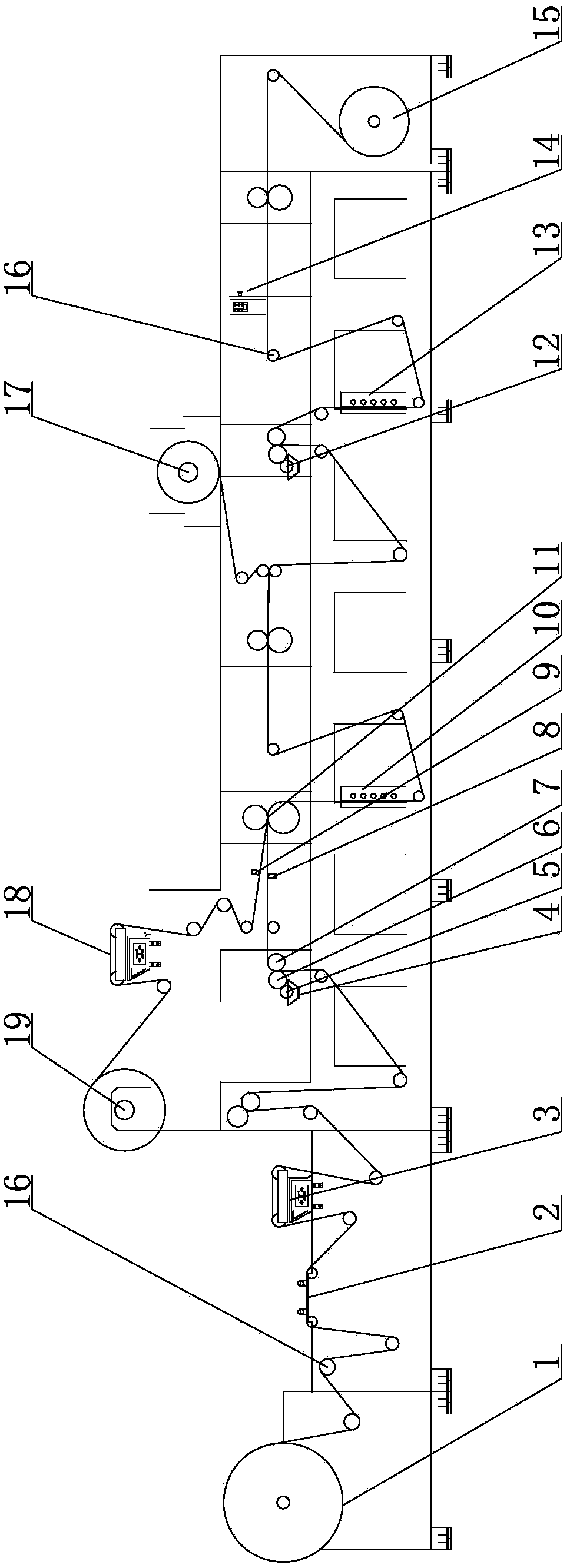

[0022] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0023] The anti-counterfeiting printing three-corresponding positioning composite method of the present invention comprises the following steps:

[0024] (1) Print the pattern on the flexographic printing machine, and print the identification cursor 1 on both sides of each plate to obtain the anti-counterfeiting label coil;

[0025] (2) Print identification cursor 2 on both sides of each plate of bronzing foil roll;

[0026] (3) Put the printed anti-counterfeit label coil, bronzing foil roll, and hot stamping plate on the three-correspondence positioning composite equipment for three-correspondence combined positioning printing, so as to realize the hot stamping and covering ink printing of the anti-counterfeit label coil at one time.

[0027] Wherein: the size of the cursor is 3-6 mm wide and 5-8 mm high, preferably a cursor with a width of 4 mm and a height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com