EPDM halogen-free flame-retardant rubber for wires and cables

A EPDM, wire and cable technology, applied in the rubber field, can solve the problem of difficult to achieve the physical properties of the cable, and achieve the effect of reducing the heat release rate, high strength and high temperature resistance and vibration damping, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

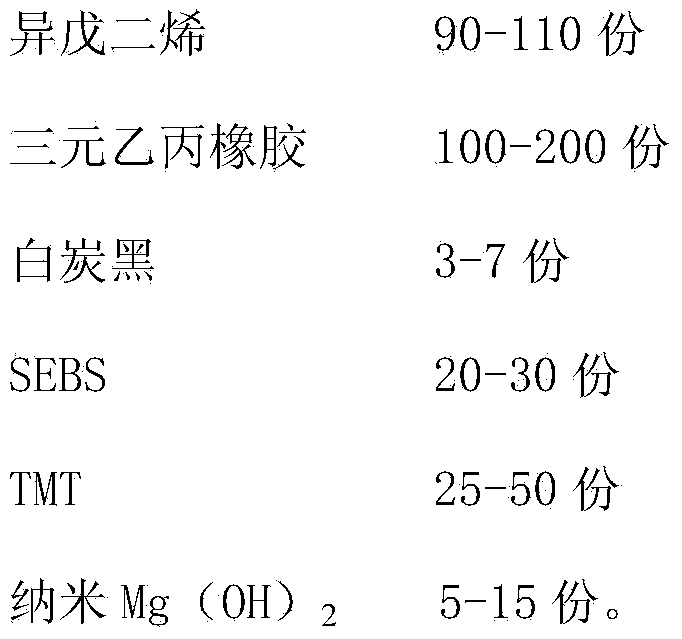

[0026] A kind of EPDM halogen-free flame-retardant rubber, its raw material comprises by weight ratio:

[0027]

[0028] The preparation method is as follows:

[0029] 1 Abrasives: put SEBS into the mill to grind the grains below 100 mesh;

[0030] 2 Mixing: Put the SEBS in step 1 and other ingredients into the mixer and mix well;

[0031] 3. Banbury mixing: the reaction kettle is first heated to 100°C, vacuumed, and the reaction kettle is emptied by N2 replacement; the raw material of step (2) is passed through, and the temperature is lowered to 60-70°C, and methylaluminoxane MAO and iron-based complexes are added A binary catalytic system composed of 2-acetyl-6-(2-methylbenimino)ethylpyridine iron chloride was reacted at 65°C and 2MPa for 30 minutes;

[0032] 4 refining: put the finished product in step 3 into a rolling machine and grind it into thin slices;

[0033] 5 Granulation: Process the finished product of step 4 into granules with a granulator;

[0034] 6 cool...

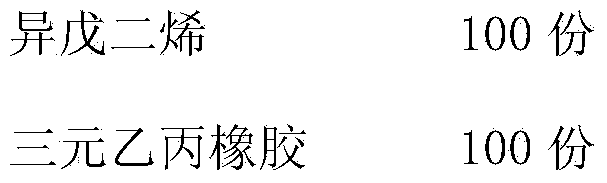

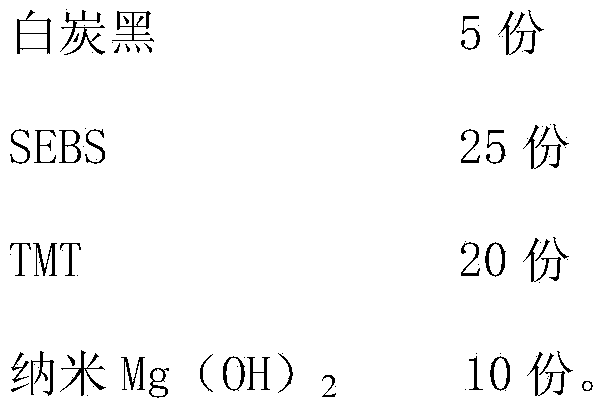

Embodiment 2

[0037]

[0038] Its preparation method is with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com