High strength, high toughness, anti-CO 2 Preparation method of corroded casing

A high-toughness, high-strength technology, applied in the direction of casing, drill pipe, earthwork drilling, etc., can solve the problems of high alloy content, high cost, waste, etc., and achieve the effect of good quality, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

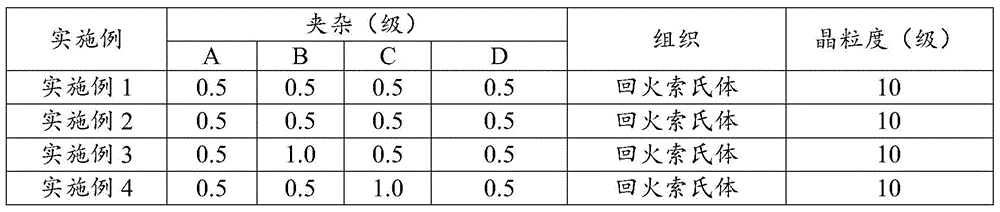

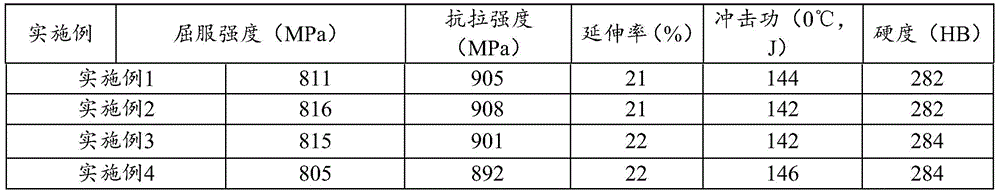

Examples

Embodiment Construction

[0016] Starting from market demand, economic benefits and social benefits, the present invention designs a reasonable chemical composition through the effects of various elements in the material, and produces steel grades with a strength of up to 110psi and impact toughness through smelting and continuous casting, piercing and rolling, and quenching and tempering processes. Far higher than API 5CT standard requirements, and good corrosion resistance, high strength, high toughness and CO2 resistance 2 Corrosion casing. The high-strength, high-toughness anti-CO 2 The specific steps of the preparation method of the corrosion casing are as follows:

[0017] Step S1: Steelmaking production

[0018] Steelmaking production includes: hot metal pretreatment, converter smelting, LF refining, VD vacuum degassing and round billet continuous casting. Nitrogen fixation technology, deoxidation technology, and clean steel technology are used in the steelmaking production process to make bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com