High-temperature titanium alloy and preparation method thereof

A high-temperature titanium alloy and alloy technology, which is applied in the field of titanium alloy, can solve the problems of complex process, expensive material cost, and high cost, and achieve the effect of reasonable chemical composition, reasonable chemical composition, and good strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a specific embodiment, the preparation method of the high-temperature titanium alloy includes: adding sponge titanium and various alloy raw materials to the raw materials in a certain order, and then melting under vacuum conditions to form an ingot, and then hot isostatic pressing, That is, the high-temperature titanium alloy is obtained;

[0048] The certain sequence is: mixing various alloy materials to obtain alloy material packages, and stacking the titanium sponge and the alloy material packages alternately; the preferred titanium sponge is divided into more than 3 layers, and the alloy material packages are divided into more than 3 layers and stacked alternately;

[0049] The smelting method is preferably as follows: heating according to the power gradient of 0-250KW, keeping the heat for 5-20 minutes after the raw material is melted, then slowly reducing the power, and cooling the furnace to room temperature; The mold is cast to obtain an alloy ingot;

[0050...

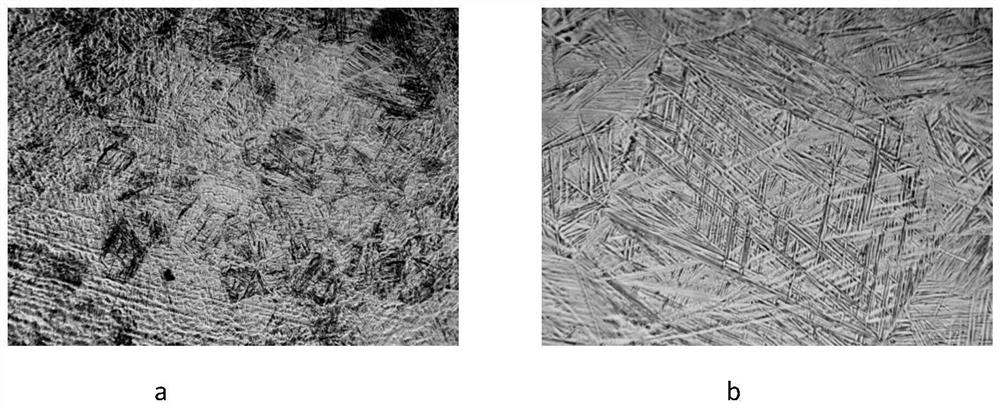

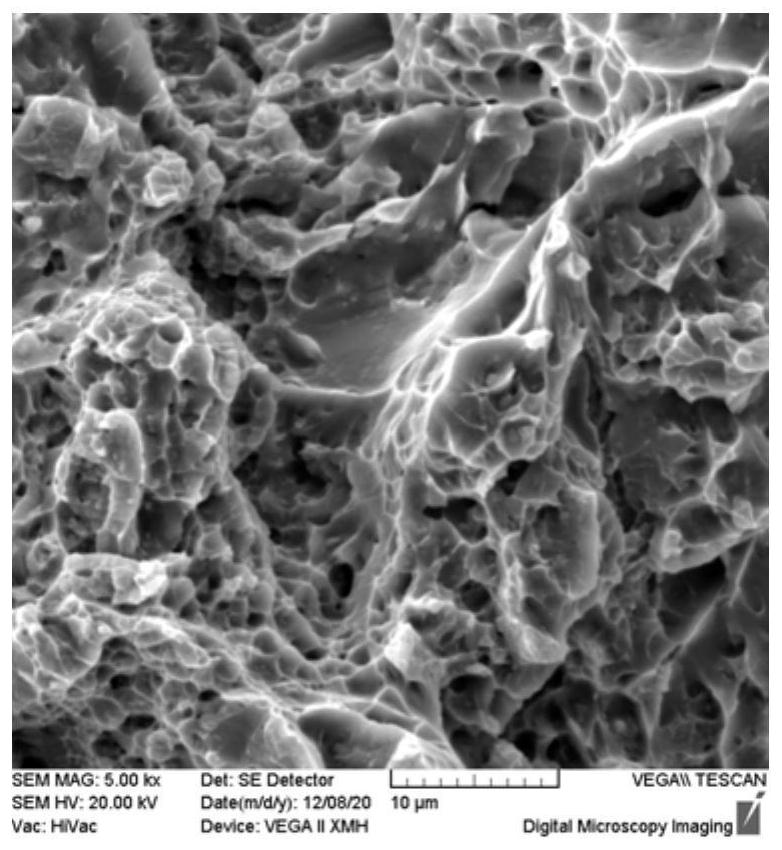

Embodiment 1

[0062] Ti-6Al-3.5Sn-8Zr-0.5Mo-0.7Nb-0.5W-0.25Si-1Ta alloy, the composition of Example 1 is listed in Table 1. The alloy is smelted three times in a vacuum induction suspension melting furnace, and the first vacuum induction suspension melting furnace is smelted: the sponge titanium and various alloy raw materials are packed according to 1 / 4 sponge titanium-1 / 3 alloy material-1 / 4 sponge Titanium—1 / 3 alloy material package—1 / 4 sponge titanium—1 / 3 alloy material package—1 / 4 sponge titanium is placed in the melting copper crucible, and then put into the vacuum induction suspension melting furnace. The secondary alloy has become a whole ingot, and it can be added directly; the melting method is to heat at 50KW first, and then increase to 70KW, 100KW, 120KW, 150KW, 170KW, 200KW, 220KW, 250KW after the charge is evenly heated and stable , keep the heat for 5 minutes after the raw material is melted, then slowly reduce the power, cool the furnace to room temperature, the power of grad...

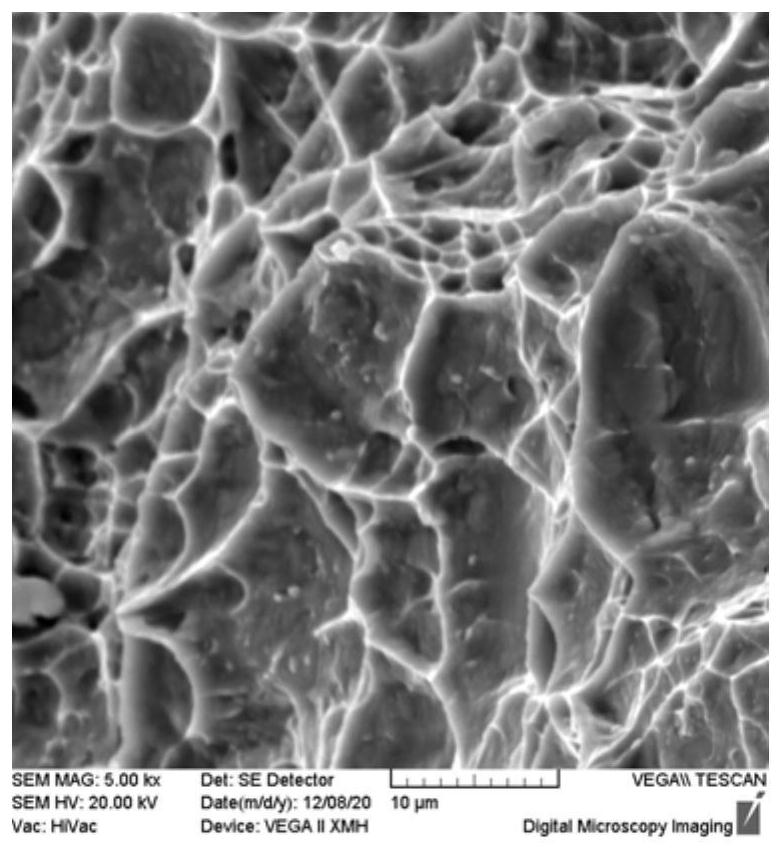

Embodiment 2

[0069] Ti-6.2Al-3.5Sn-8Zr-0.6Mo-0.8Nb-1W-0.25Si alloy, the composition of Example 2 is listed in Table 3. The alloy is smelted three times in a vacuum induction suspension melting furnace, and the first vacuum induction suspension melting furnace is smelted: the sponge titanium and various alloy raw materials are packed according to 1 / 4 sponge titanium-1 / 3 alloy material-1 / 4 sponge Titanium—1 / 3 alloy material package—1 / 4 sponge titanium—1 / 3 alloy material package—1 / 4 sponge titanium is placed in the melting copper crucible, and then put into the vacuum induction suspension melting furnace. The secondary alloy has become a whole ingot, and it can be added directly; the melting method is to heat at 50KW first, and then increase to 70KW, 100KW, 120KW, 150KW, 170KW, 200KW, 220KW, 250KW after the charge is evenly heated and stable , keep the heat for 5 minutes after the raw material is melted, then slowly reduce the power, cool the furnace to room temperature, the power of gradient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com