UOE welded pipe with excellent deformability and manufacturing method thereof

A manufacturing method and technology for welded pipes are applied in the field of welded pipes and their manufacturing to achieve the effect of improving plate shape and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

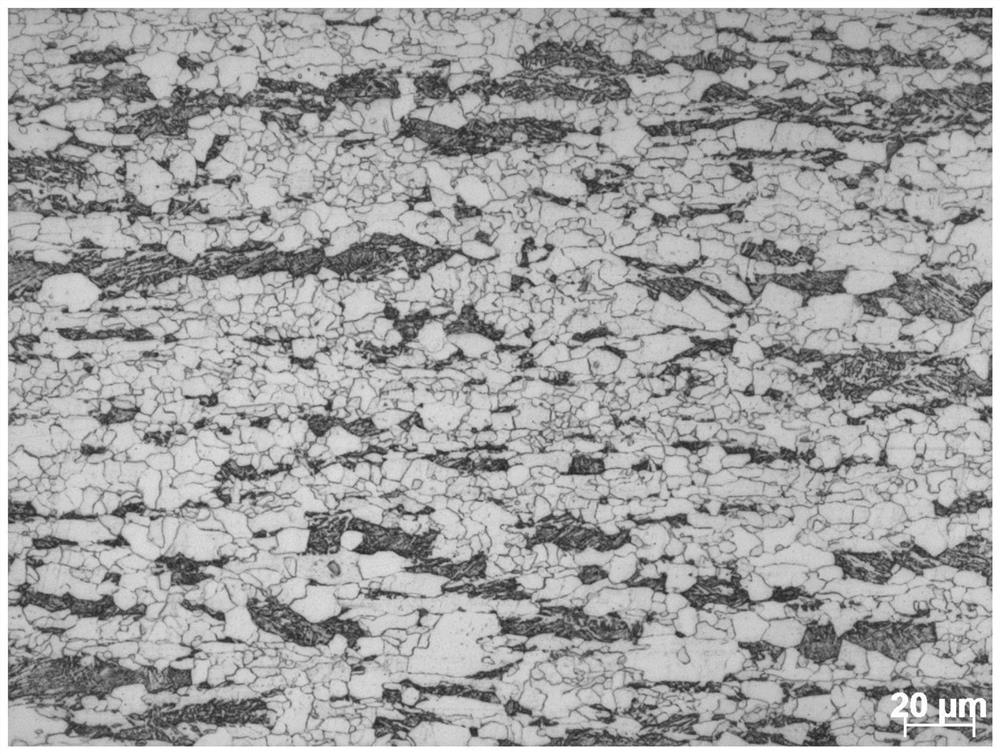

Image

Examples

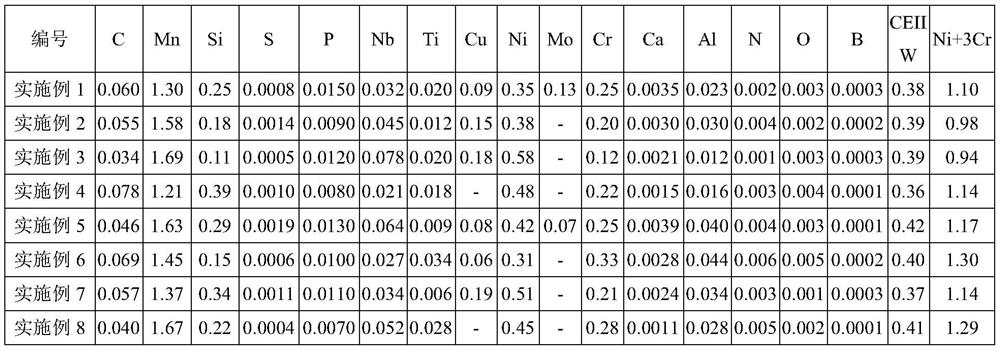

Embodiment 1-8

[0088] The UOE welded pipes with excellent deformability in Examples 1-8 were all prepared by the following steps:

[0089] (1) Smelting and casting according to the chemical composition shown in Table 1: After smelting-LF+RH refining-continuous casting and other processes, a continuous casting slab with a thickness of 300-400mm is obtained;

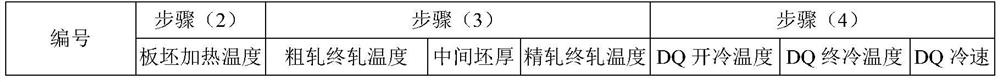

[0090] (2) Heating: Control the slab heating temperature to 1070-1170°C;

[0091] (3) Rolling: Control the finishing temperature of rough rolling to 950-1050°C, the thickness of the intermediate billet to 3t-7t, where t represents the wall thickness of the steel pipe, and control the finish rolling temperature to 730-820°C;

[0092] (4) Air cooling + DQ cooling: control the start cooling temperature of DQ cooling to 640-690°C, control the final cooling temperature of DQ cooling to 100-350°C, and control the cooling rate of DQ cooling to 25-45°C / s;

[0093] (5) Pipe making: the steel plate is sequentially subjected to C forming, U formin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com