Solar photovoltaic cable

A solar photovoltaic and cable technology, which is applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of unsatisfactory, restricted, increased R&D costs and production costs, etc., and achieve the effect of long service life and high electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

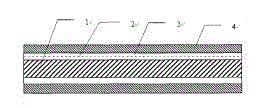

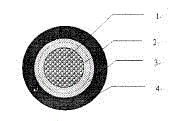

[0031] Such as figure 1As shown, the solar photovoltaic cable mainly includes a conductor 1, a sheath 4, an inner insulation layer 2 and an outer insulation layer 3. Linked polyolefin material, the outer insulating layer 3 adopts extruded low-smoke, halogen-free, flame-retardant irradiation cross-linked polyolefin ring material from -40°C to 125°C, they are adhered and not easy to separate, and the inner insulating layer and the outer insulating layer The layer adopts high-precision machine head and non-adjustable tungsten steel mold, double-head co-extrusion, online infrared dynamic outer diameter tester and online dynamic core eccentricity tester, which ensure the stability of production and product quality, and effectively reduce production costs. Among them, the internal insulation adopts a volume resistance of 1.0×1014 ~ 9.0×1017Ω cm at 20°C; apply a 600V sine wave voltage of 48 ~ 62HZ, soak in water at 90°C for more than 12 weeks, and the minimum insulation resistance pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com