Production technology of gardening edible mushroom blocks

A production process and edible fungus technology, which is applied to the production process field of horticultural edible fungus blocks, can solve the problems of complex procedures, increased cost, low production efficiency, etc., so as to reduce the cultivation pollution rate, prevent the invasion of miscellaneous bacteria, and improve the production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

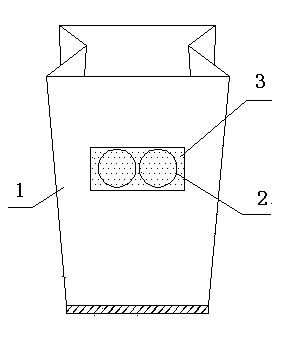

[0020] Example 1 A production process of horticultural edible fungus block, the steps are as follows: 1) After adding water and stirring wood chips and wheat bran, the bagging machine of Japan Tanaka Giken Industry Co., Ltd. is used for automatic bagging, bagging, and briquetting , to ensure that the water content of the medium is 60%. Bagging and bagging. 2) Autoclave at 105°C for 120 minutes, then cool to room temperature; 3) Inoculate with a fully automatic inoculation machine, inoculation temperature 5-15 degrees, 2-5s / block; 4) Use continuous sealing machine heat sealing, sealing machine heat sealing The temperature is 150°C and the time is 20s. ; 5) Mycelia culture was carried out under the conditions of temperature 16°C, humidity 60%, and carbon dioxide concentration 500ppm. Wherein, the bacteria bag such as figure 1 As shown, it is an upright plastic bag 1 with a vent hole 2, the vent hole 2 is covered with a breathable film 3, and the vent film 3 and the vent hole ...

Embodiment 2

[0021] Embodiment 2 A production process of horticultural edible fungus block, the steps are as follows: 1) Add water and stir the sawdust and wheat bran, and then use the bagging machine of Japan Tanaka Giken Industry Co., Ltd. to automatically bag, bag, and briquetting, Ensure that the water content of the medium is 66%. 2) Autoclave at 130°C for 60 minutes, then cool to room temperature; 3) Inoculate with an automatic inoculation machine, inoculation temperature 5-15 degrees, 2-5s / block; 4) Use continuous sealing machine heat sealing, sealing machine heat sealing The temperature is 260°C, and the time is 5s; 5) Mycelium culture is carried out under the conditions of temperature 26°C, humidity 85%, and carbon dioxide concentration 3000ppm. Wherein, the bacteria bag such as figure 1 As shown, it is an upright plastic bag 1 with a vent hole 2, the vent hole 2 is covered with a breathable film 3, and the vent film 3 and the vent hole 2 are heat-sealed and connected.

Embodiment 3

[0022] Embodiment 3 A production process of horticultural edible fungus block, the steps are as follows: 1) After adding water and stirring wood chips and wheat bran, the bagging machine of Japan Tanaka Giken Industry Co., Ltd. is used for automatic bagging, bagging, and briquetting. Ensure that the water content of the medium is 65%. 2) Autoclave at 115°C for 100 minutes, then cool to room temperature; 3) Inoculate with an automatic inoculation machine, inoculate at a temperature of 5-15°C, 2-5s / block; 4) Heat seal with a continuous sealing machine, and heat seal with a sealing machine The temperature is 200°C and the time is 10s. ; 5) Mycelium culture was carried out under the conditions of temperature 20°C, humidity 75%, and carbon dioxide concentration 1500ppm. Wherein, the bacteria bag such as figure 1 As shown, it is an upright plastic bag 1 with a vent hole 2, the vent hole 2 is covered with a breathable film 3, and the vent film 3 and the vent hole 2 are heat-sealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com