Sleeve-fish frozen prepared food and processing method thereof

A technology for freezing conditioning and food processing, applied in the field of food processing, can solve problems such as single squid product, and achieve the effects of moderate saltiness, uniform texture and golden color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Pretreatment

[0023] Use frozen Peruvian squid as raw material, thaw it in running water until it is slightly frozen, cut off the head, remove the viscera and cartilage, rinse with cooling water to remove residual viscera, mucus, etc., soak and disinfect the squid carcass with ozone water, and then rinse and disinfect the squid carcass. Sour taste remover mainly composed of sodium carbonate, sodium bicarbonate, sodium citrate and sodium tartrate was used to deacidify squid. Cut the deacidified squid into squid strips with a length of 1.8-2.2 cm and a width of 1.0-1.5 cm,

[0024] (2) Marinated and seasoned

[0025] The squid strips are marinated and seasoned with spices. The spices are a mixture of chili powder and five-spice powder. The ratio of chili powder and five-spice powder is 2:1 to 1:2. Spices and squid meat were marinated in a mass ratio of 1:40, and the time was 60 minutes. When marinating, the marinade must be in full contact with the squid strips, ...

Embodiment 2

[0038] Based on Argentine or North Pacific squid. During pretreatment squid, there is no deacidification process after disinfection, and other processing methods are with embodiment 1.

[0039] 2. Sensory evaluation method

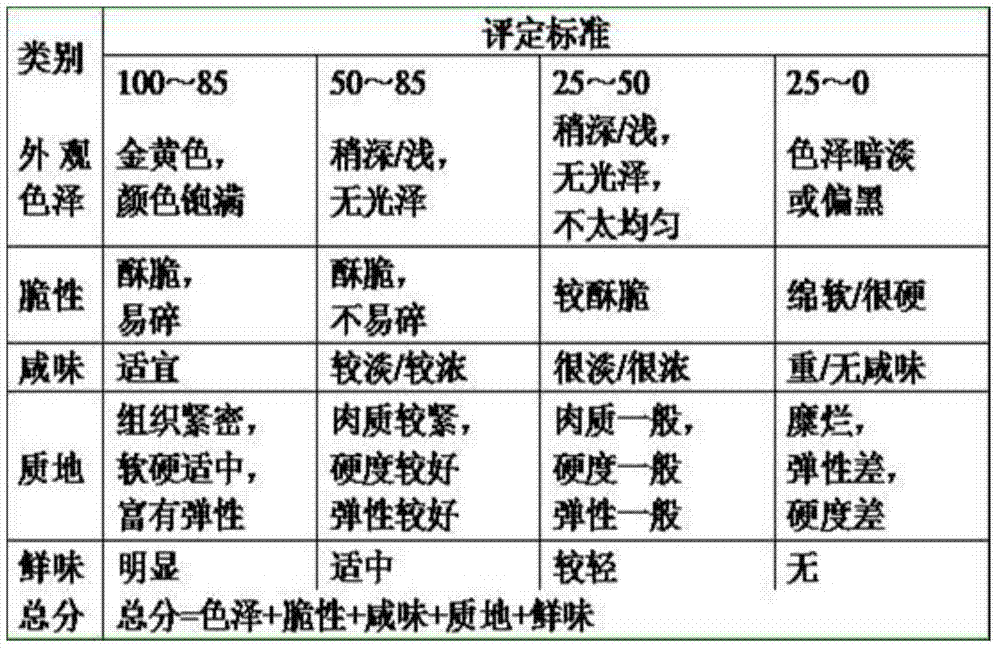

[0040] The above-mentioned frozen conditioning squid cake can be eaten by frying when eating. The taste after frying is judged by a panel of 10 specially trained sensory evaluators. According to the way of smelling first and then eating, the five aspects of appearance, color, crispness, saltiness, texture and umami are expressed by scores. Comprehensive evaluation, the total score is the comprehensive score of the above five indicators. The score distribution of the five indicators is as follows: 20% appearance color, 20% crispness, 10% salty taste, 30% texture, and 20% umami taste. The specific evaluation criteria and evaluation rules are shown in the table.

[0041] Sensory evaluation criteria for squid cakes

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com