A heavy-floating combined separation process for coking middling coal

A process and sorting technology, applied in the field of mineral processing, can solve the problems of high production cost and complicated process, and achieve the effect of fewer equipment links, simple process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

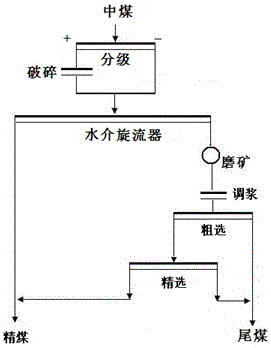

[0034] Implementation Mode 1: Taking the heavy-medium medium coal of A coal preparation plant as the research object, according to figure 1 The re-election "head pulling" technological process operation, the specific steps are:

[0035] (1) Coal crushing in coking

[0036] After being sieved by a grading sieve with a sieve hole of 3mm, use a hammer crusher to crush the 50~3mm sieve material to make the particle size below 3mm;

[0037] (2) Hydrocyclone re-election

[0038] Weigh 13kg of material with a particle size below 3mm, pour it into a mixing tank, and mix it with water to prepare a slurry with a concentration of 100 g / L; through the slurry pump, the slurry enters a new type of water-based cyclone—coal slime cyclone along the tangential direction Gravity separation column (cylinder diameter φ150mm, overflow outlet diameter 45mm, underflow outlet diameter 22mm, overflow pipe insertion depth 100mm), when the feeding pressure is 0.12MPa, the cyclone overflows through the ...

Embodiment approach 2

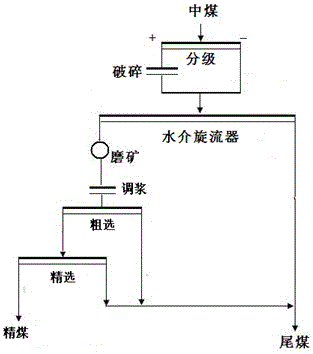

[0042] Implementation Mode 2: Taking the heavy-medium medium coal of B coal preparation plant as the research object, according to figure 2 Re-select the direct "tail throwing" process to operate, the specific steps are:

[0043] (1) Coal crushing in coking

[0044] After being sieved by a grading sieve with a sieve hole of 3mm, use a hammer crusher to crush the 50~3mm sieve material to make the particle size below 3mm;

[0045] (2) Hydrocyclone re-election

[0046] Weigh 13kg of material with a particle size below 3mm, pour it into a mixing tank, mix it with water to prepare a slurry with a concentration of 100 g / L; use a slurry pump to make the slurry enter the water-mediated cyclone along the tangential direction—coal slime cyclone weight Column selection (cylinder diameter φ150mm, overflow outlet diameter 45mm, underflow outlet diameter 19mm, overflow pipe insertion depth 140mm), when the feeding pressure is 0.12MPa, it can realize reelection "tail throwing", and the th...

Embodiment approach 3

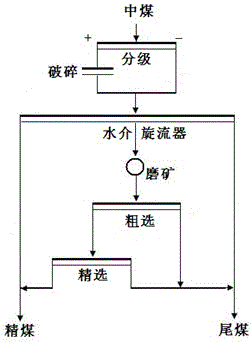

[0050] Implementation Mode 3: For the medium coal whose selectivity is between the dense medium medium coal of A and B coal preparation plants, according to image 3 Gravity separation directly "pulls the head" and "throws the tail", and re-separation ore grinding flotation.

[0051] (1) Coal crushing in coking

[0052] After being sieved by a grading sieve with a sieve hole of 3mm, use a hammer crusher to crush the 50~3mm sieve material to make the particle size below 3mm;

[0053] (2) Hydrocyclone re-election

[0054] Weigh 13kg of material with a particle size below 3mm, pour it into a mixing tank, and mix it with water to prepare a slurry with a concentration of 100 g / L; through the slurry pump, the slurry enters the two-stage new water-mediated cyclone group along the tangential direction— Coal slime cyclone gravity separation column (the diameter of the first and second sections of the cylinder is φ150mm, the diameter of the first section of the overflow port is 40mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com