Special shading and cooling greenhouse film for culturing edible fungi

A greenhouse film, edible fungus technology, applied in the application, greenhouse cultivation, climate change adaptation and other directions, can solve the problems of being unable to resist sunlight, no solution, unfavorable growth of edible fungi, etc., to achieve excellent mechanical and weather resistance performance, extended Effectiveness of service life, yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

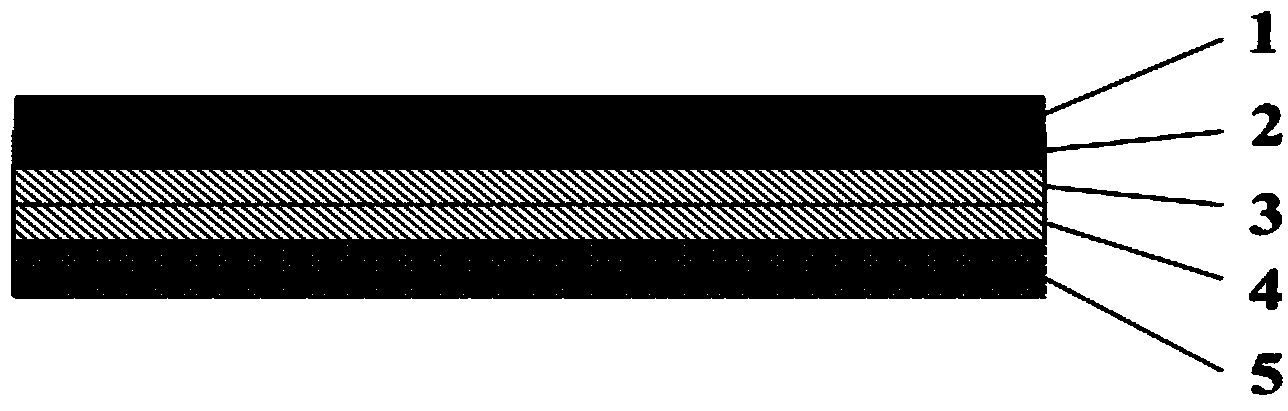

[0032] What is described is a kind of shading and cooling greenhouse film specially used for cultivating edible fungi. From the outside to the inside, there are light-transmitting protective layer 1, silver reflective layer 2, first milky white reflective layer 3, second milky white reflective layer 4 and black heat preservation layer. 5.

[0033] Wherein, the light-transmitting protective layer 1 is a BOPET film with a thickness of 15 μm and a light transmittance of 97%. The main function of this layer is to protect the silver reflective layer 2 from being scratched and affect the reflectivity. The high light transmittance of BOPET can ensure that almost all sunlight enters the surface of the next layer of film and is reflected.

[0034] The thickness of the silver reflective layer 2 is 20 μm. Among its main components, the substrate is a co-extruded film of LLDPE and LDPE, the contents are 30% and 55% respectively, and the aluminum powder is 3000 mesh, and the addition amoun...

Embodiment 2

[0042] What is described is a kind of shading and cooling greenhouse film specially used for cultivating edible fungi. From the outside to the inside, there are light-transmitting protective layer 1, silver reflective layer 2, first milky white reflective layer 3, second milky white reflective layer 4 and black heat preservation layer. 5.

[0043] Among them, the light-transmitting protective layer 1 is a modified PP film with a thickness of 20 μm and a light transmittance of 96%; the thickness of the silver reflective layer 2 is 25 μm. Among its main components, the substrate is a co-extruded film of LLDPE and LDPE, and the content is 55%, 25%, aluminum powder 1500 mesh, and the addition amount is 20%; the thickness of the first opalescent reflective layer 3 is 25 μm, among its main components, the matrix is a co-extruded film of LLDPE and LDPE, the content is 55%, 30% respectively, and the inorganic filler is Titanium dioxide, 800 mesh, the addition amount is 15%; The thic...

Embodiment 3

[0048] What is described is a kind of shading and cooling greenhouse film specially used for cultivating edible fungi. From the outside to the inside, there are light-transmitting protective layer 1, silver reflective layer 2, first milky white reflective layer 3, second milky white reflective layer 4 and black heat preservation layer. 5.

[0049] Among them, the light-transmitting protective layer 1 is a (mLLDPE+LLDPE+LDPE) film with a thickness of 24 μm and a light transmittance of 97%; the thickness of the silver reflective layer 2 is 30 μm. Among its main components, the substrate is a co-extruded film of LLDPE and LDPE, and the contents are respectively 30% and 60%, aluminum powder 1000 mesh, and 10% added; the thickness of the first milky white reflective layer 3 is 30 μm, and its main component is a co-extruded film of LLDPE and LDPE, and the content is 35% and 50% respectively , the inorganic filler is calcium carbonate, 500 mesh, and the addition amount is 15%; the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com