Method for extracting theanine from fresh tea

A technology of fresh tea and theanine, which is applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems of low purity and achieve the effects of high purity, short production cycle and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

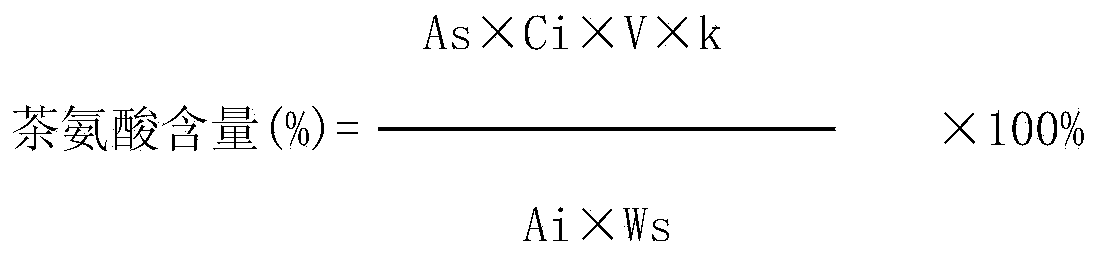

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of method extracting theanine from fresh tealeaves, it comprises the following steps:

[0024] S1. Soaking: put 2,000 kg of fresh tea leaves in a container, add 10,000 kg of purified water, soak at a constant temperature for 1.8 hours, and pass the mixed solution in the container through a 18-mesh sieve to obtain a filtrate; wherein, the soaking temperature at a constant temperature is 65°C;

[0025] S2. Centrifugation: Centrifuge the filtrate for 50 minutes under an environment with a temperature of 30° C. and a pressure of 0.1 MPa, discard the precipitate, and use the centrifuge for the next operation; wherein, the speed of the centrifuge is 6500 rpm;

[0026] S3. Concentration once: use a reverse osmosis membrane with a molecular weight cut-off of 100 to concentrate the centrifugate at a concentration temperature of 30°C until the solid content is 5%;

[0027] S4. Primary adsorption: load the concentrated solution on LX-8 resin, elute with 70% et...

Embodiment 2

[0035] Embodiment 2: a kind of method extracting theanine from fresh tealeaves, it comprises the following steps:

[0036] S1. Soaking: put 2000kg of fresh tea leaves in an extractor, add 16000kg of purified water, soak at a constant temperature for 2.5 hours, pass the mixed solution in the extractor through a 24-mesh sieve to obtain a filtrate; wherein, the constant temperature soaking temperature is 100°C ;

[0037] S2. Centrifugation: Centrifuge the filtrate for 70 minutes under an environment with a temperature of 50° C. and a pressure of 0.3 MPa, discard the precipitate, and use the centrifugate for the next step; wherein, the speed of the centrifuge is 7000 rpm;

[0038] S3. Primary concentration: Concentrate the centrifugate with a reverse osmosis membrane with a molecular weight cut-off of 100 at a concentration temperature of 50°C until the solid content is 10%;

[0039] S4. Primary adsorption: load the concentrated solution on LX-8 resin, elute with 75% ethanol, and...

Embodiment 3

[0047] Embodiment 3: a kind of method extracting theanine from fresh tealeaves, it comprises the following steps:

[0048] S1. Soaking: put 2000kg of fresh tea leaves in an extractor, add 12000kg of purified water, soak at a constant temperature for 2 hours, pass the mixed solution in the container through a 20-mesh sieve to obtain a filtrate; wherein, the soaking temperature at a constant temperature is 85°C;

[0049] S2. Centrifugation: Centrifuge the filtrate for 60 minutes in an environment with a temperature of 38°C and a pressure of 0.25 MPa, discard the precipitate, and use the centrifuge for the next step; wherein, the speed of the centrifuge is 6800 rpm;

[0050] S3. Primary concentration: Concentrate the centrifugate with a reverse osmosis membrane with a molecular weight cut-off of 100 at a concentration temperature of 42°C until the solid content is 10%;

[0051] S4. Primary adsorption: load the concentrated solution on LX-8 resin, elute with 72% ethanol, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com