A logistics heat recovery process and device in an acrylonitrile production device

A production device and technology of acrylonitrile, applied in the chemical industry, sustainable manufacturing/processing, preparation of hydrocarbon ammoxidation, etc., can solve the problems of high manufacturing cost, small effective heat transfer temperature difference, large heat transfer area, etc., and achieve increased Effective heat transfer temperature difference, reduced heat transfer area, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. See Table 1 for the operating conditions and composition of the stream S1 drawn from the sideline in the liquid collection tank in the middle section of the absorption tower T1.

[0038] Table 1

[0039] Media Name

unit

S1

Mass proportion (%wt)

kg / h

0.5

0.0002

water

kg / h

262738.6

98.9828

heavy fraction 1

kg / h

1323.5

0.4986

heavy fraction 2

kg / h

732.8

0.2761

heavy fraction 3

kg / h

642.6

0.2421

kg / h

0.3

0.0001

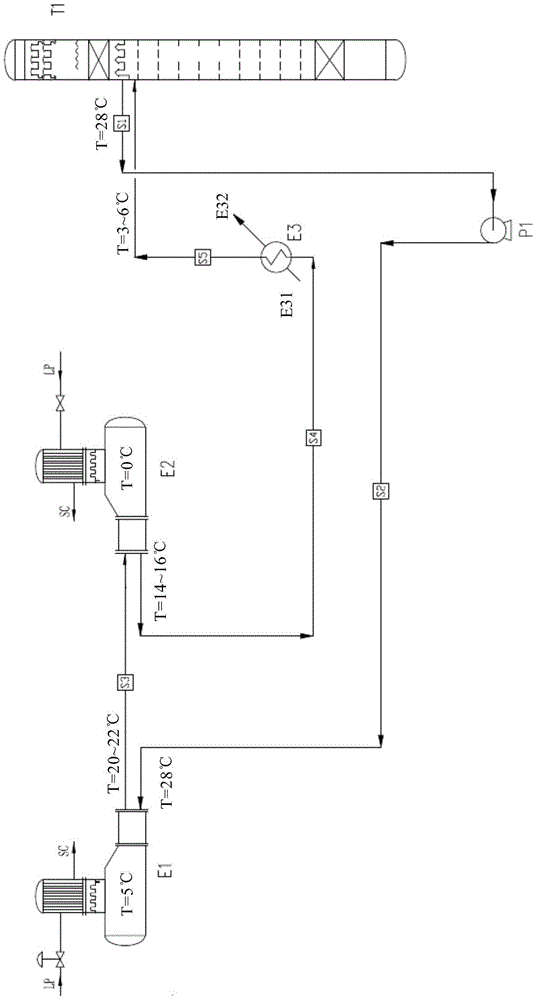

kg / h

0.2

0.0001

total flow rate

kg / h

265438.7

100.0

[0040] operating temperature

℃

28

operating pressure

MPaA

0.1184

[0041] 2. Reference figure 1 , figure 1 It is a schematic flow chart of the process for recovering heat from the side stream of the absorption tower of the acrylonitrile plant according to Example 1 of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com