Camellia oleifera Abel saponin compound, its preparation method, application and antitumor drug prepared from the same

An anti-tumor drug, the technology of camellia oleifera saponin, which is applied in the field of anti-tumor drugs and can solve problems such as different combination methods and complex aglycon structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

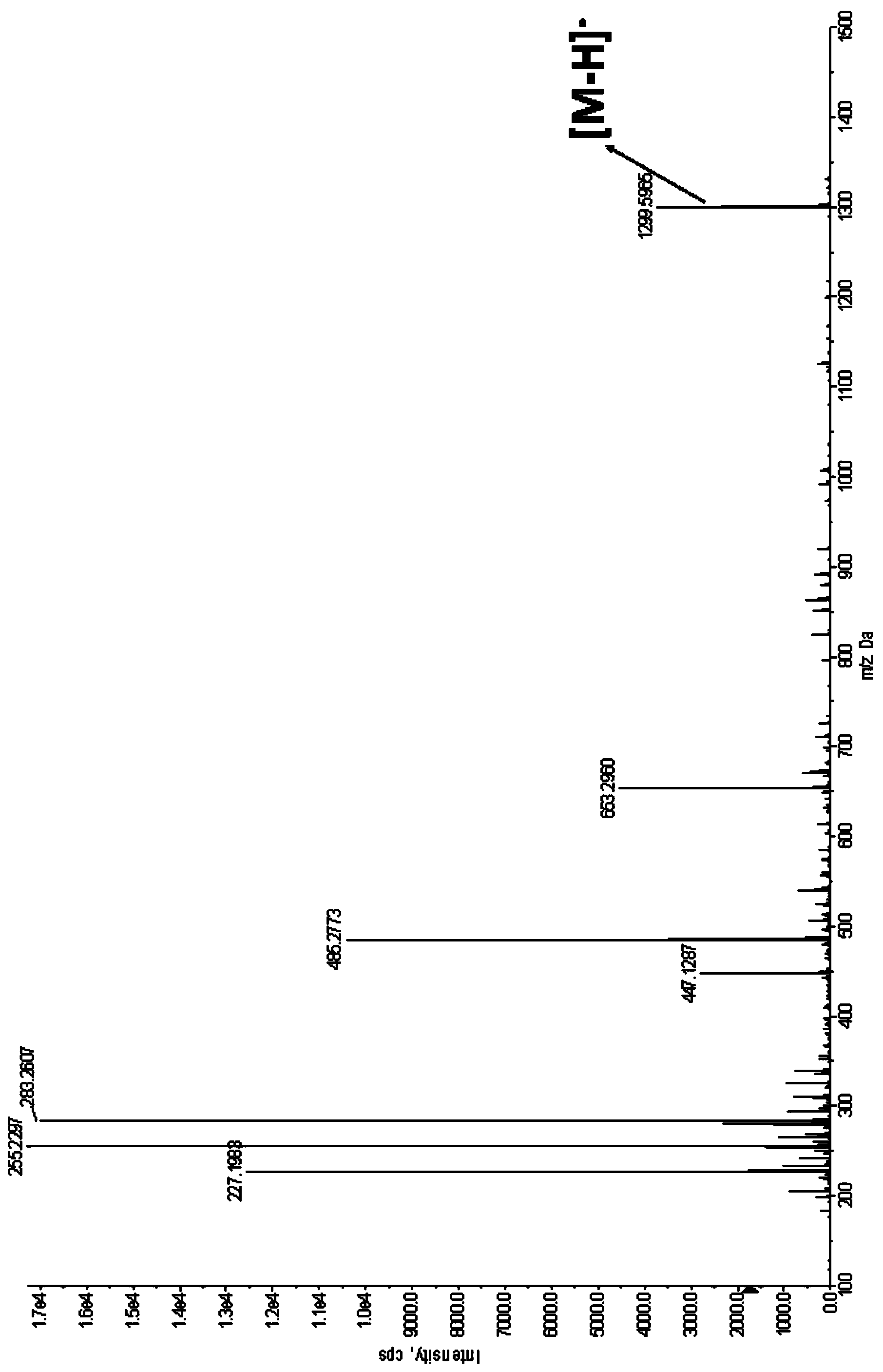

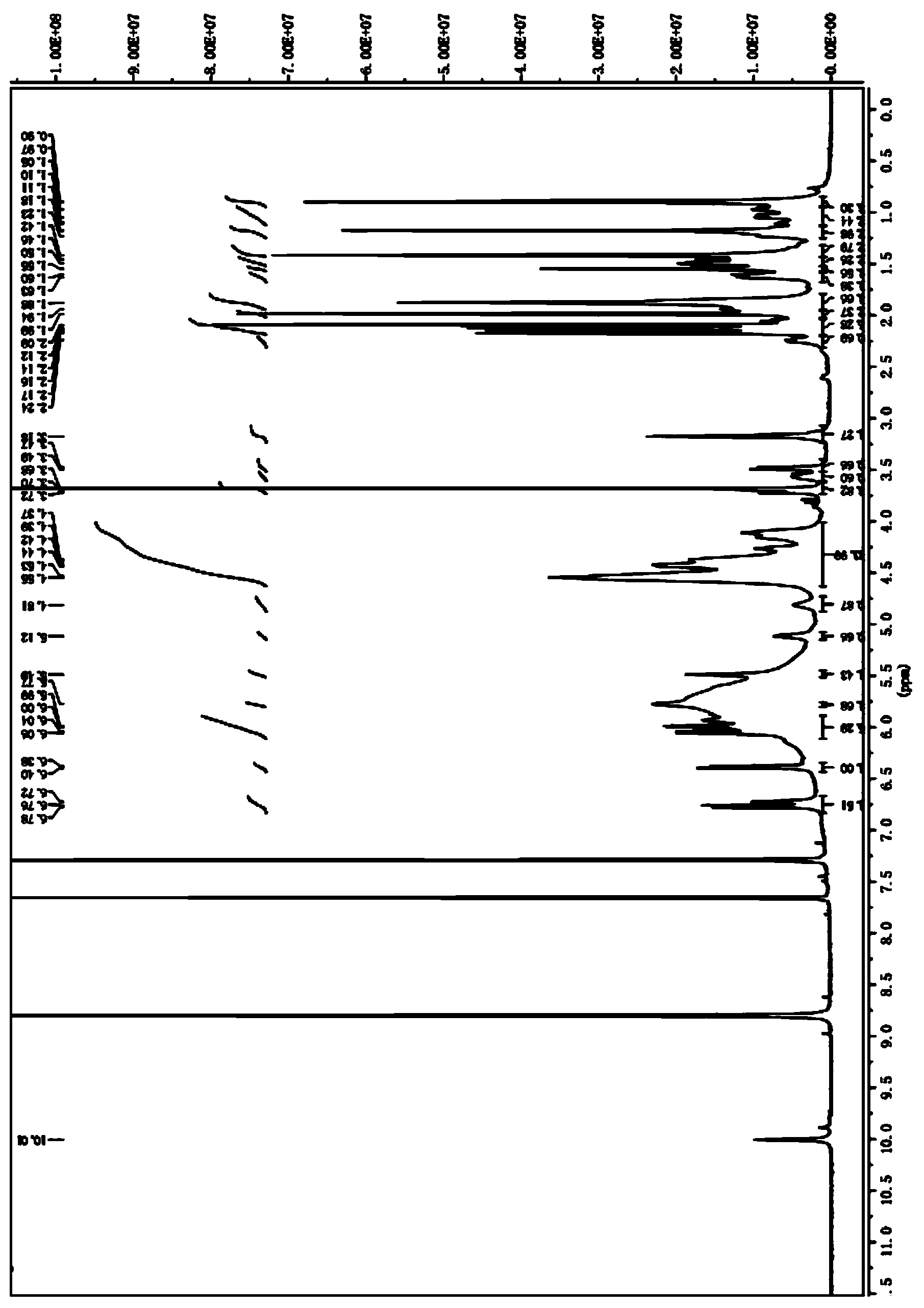

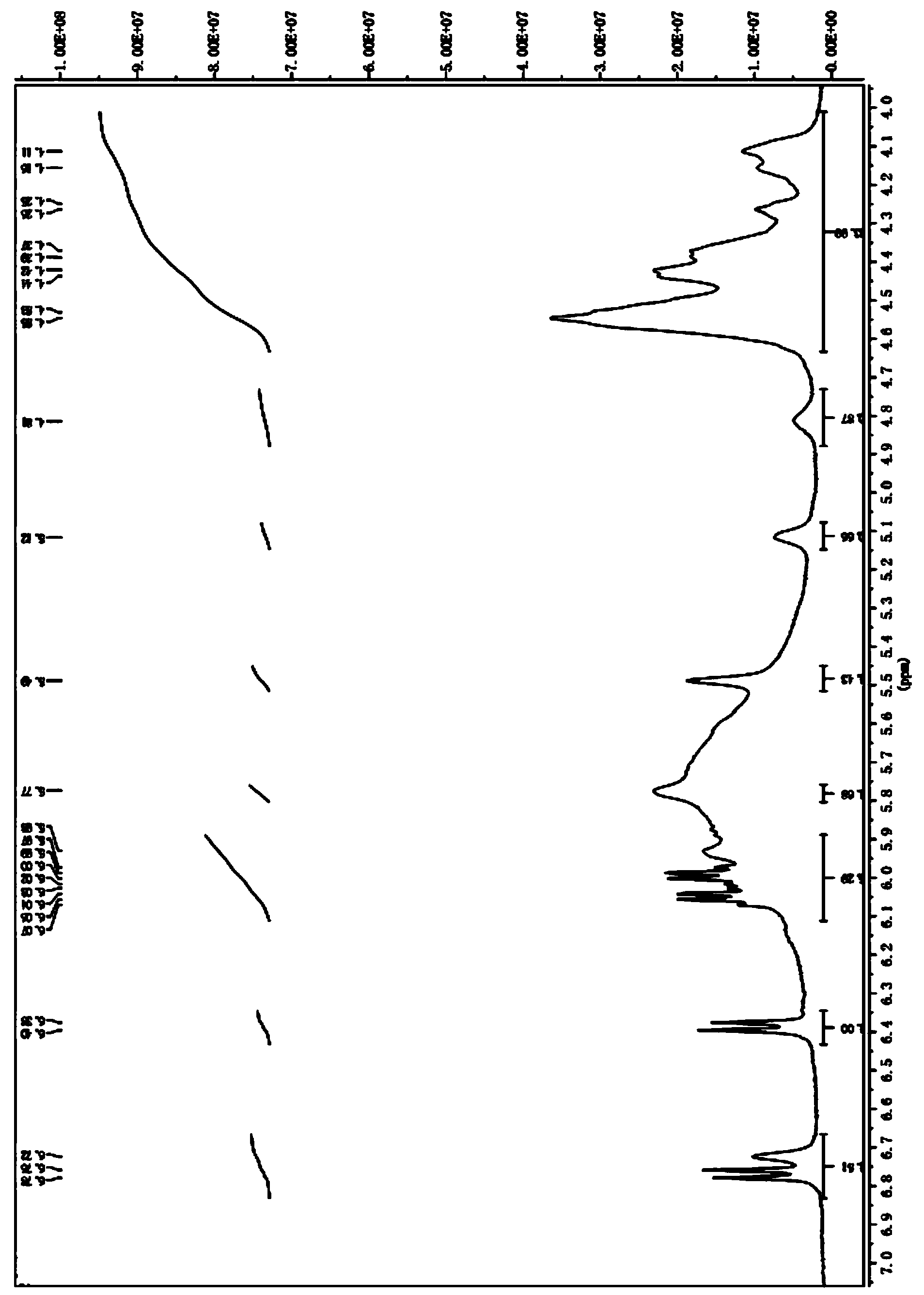

[0082] Embodiment 1 has the preparation of the camellia saponin compound of structure shown in formula I

[0083] extract:

[0084] Take 2000g of dry Camellia oleifera root (collected from Qichun, Hubei in November 2011), crush it into sawdust with a grinder, add 20.0L of 70% ethanol aqueous solution, soak at 40°C for 10h, heat to reflux, and extract 3.0h, collect the extract, filter the extract, concentrate under reduced pressure to obtain 602g of liquid extract.

[0085] Macroporous resin enrichment:

[0086] Take the liquid extract obtained in the extraction step, add 6.02L of water, stir to dissolve, filter with a 100-mesh filter cloth, and centrifuge the filtrate at 12000r / min for 10min. After centrifugation, 5.3L of supernatant is obtained. Pore resin was further separated, and eluted successively with 10L water, 15L 30% ethanol aqueous solution, and 15L 70% ethanol aqueous solution, collected 70% ethanol aqueous solution eluted components, and concentrated under red...

Embodiment 2

[0112] Embodiment 2 has the preparation of the camellia saponin compound of structure shown in formula I

[0113] extract:

[0114] Take 2000g of dry Camellia oleifera root (collected from Qichun, Hubei in November 2011), crush it into sawdust with a grinder, add 40.0L of 30% ethanol aqueous solution, soak at 30°C for 12h, heat to reflux, and extract three times , 0.5h each time, collect the extract, filter the extract, concentrate under reduced pressure, and obtain 628g of liquid extract.

[0115] Macroporous resin enrichment:

[0116] Take the liquid extract obtained in the extraction step, add 0.628L of water, stir to dissolve, filter with a 300-mesh filter cloth, and centrifuge the filtrate at 12000r / min for 10min. After centrifugation, 5.8L of supernatant is obtained. Pore resin was further separated, and eluted with 10L water, 15L 60% ethanol aqueous solution, 10L 95% ethanol aqueous solution successively, collected 95% ethanol aqueous solution elution component, con...

Embodiment 3

[0127] Embodiment 3 has the preparation of the camellia saponin compound of structure shown in formula I

[0128] extract:

[0129] Take 2000g of dry Camellia oleifera root (collected from Qichun, Hubei), grind it into sawdust with a grinder, add 10.0L of 95% ethanol aqueous solution, soak at 50°C for 6h, heat to reflux, and extract twice, each After 1 hour, the extract was collected, filtered, and concentrated under reduced pressure to obtain 638 g of liquid extract.

[0130] Macroporous resin enrichment:

[0131] Take the liquid extract obtained in the extraction step, add 6.0L of water, stir to dissolve, filter with a 200-mesh filter cloth, and centrifuge the filtrate at 12000r / min for 10min. After centrifugation, 5.5L of supernatant is obtained. Porous resin was further separated, and eluted with 10.0L water, 15.0L40% ethanol aqueous solution, and 15.0L L80% ethanol aqueous solution successively, collected 80% ethanol aqueous solution eluted fraction, concentrated under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com