A method for synthesizing biodegradable plastics from aerobic granular sludge

A technology of aerobic granular sludge and synthetic organisms, applied in the direction of fermentation, can solve problems such as collapse, poor reactor stability, sludge bulking, etc., and achieve the effects of not easy filamentous bacteria bulking, fast synthesis speed, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: a kind of method of using aerobic granular sludge to synthesize biodegradable plastics of the present embodiment, it is carried out according to the following steps:

[0018] 1. Put the activated sludge in the SBR reactor with a height-to-diameter ratio of 10:1, so that the sludge concentration in the reactor reaches 3000-5000mg / L;

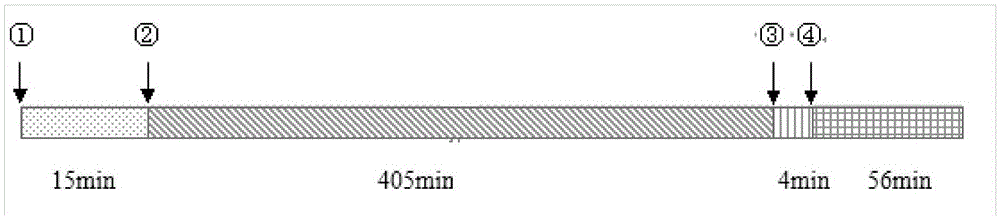

[0019] 2. The SBR reactor is operated with a cycle of 6 to 8 hours. The operation process of one cycle of the SBR reactor is as follows: after the water inflow is completed, the temperature of the SBR reactor is 23°C to 27°C. Aeration, after the dissolved oxygen in the SBR reactor jumps from 2 to 3mg / L to 6 to 7mg / L, continue to aerate until 30 minutes before the end of the current cycle, stop the aeration, then carry out precipitation for 3 to 5 minutes, and drain water; Among them, the incoming water contains carbon source, nitrogen source and phosphorus source, its chemical oxygen demand is 5000-10000mg / L, and th...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 2, aeration is started when the temperature of the reactor is 25°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the carbon sources are all small molecule organic acids. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com