Calibration device for solar telescope heat field diaphragm internal seeing effect

A thermal field diaphragm and solar telescope technology, which is applied in the field of seeing effect measurement inside the solar telescope, can solve problems such as the internal seeing effect of the thermal field diaphragm that is not easy to achieve, and achieve fast online detection, and the method is simple and easy line, the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

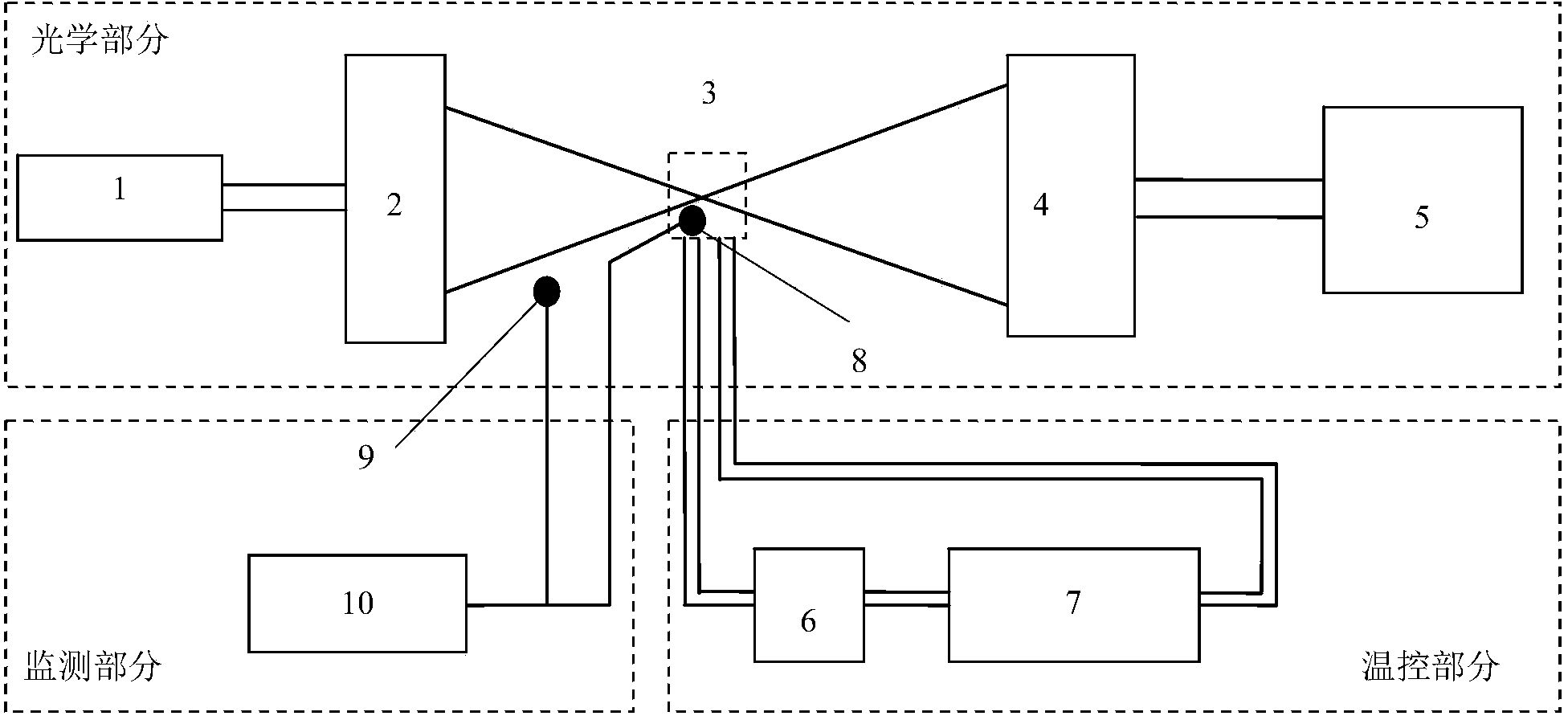

[0055] A possible implementation of a seeing degree effect calibration device inside the thermal field diaphragm of a solar telescope, specifically:

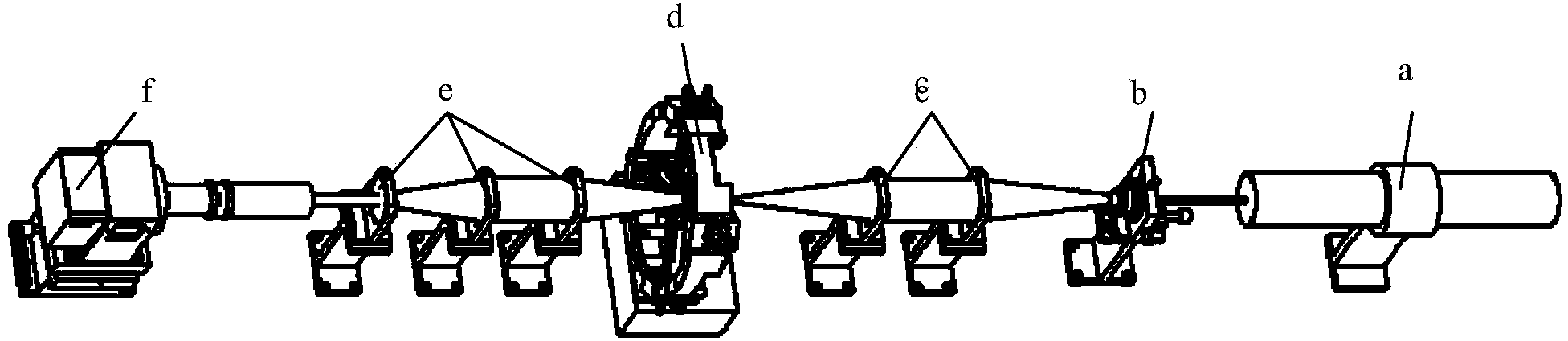

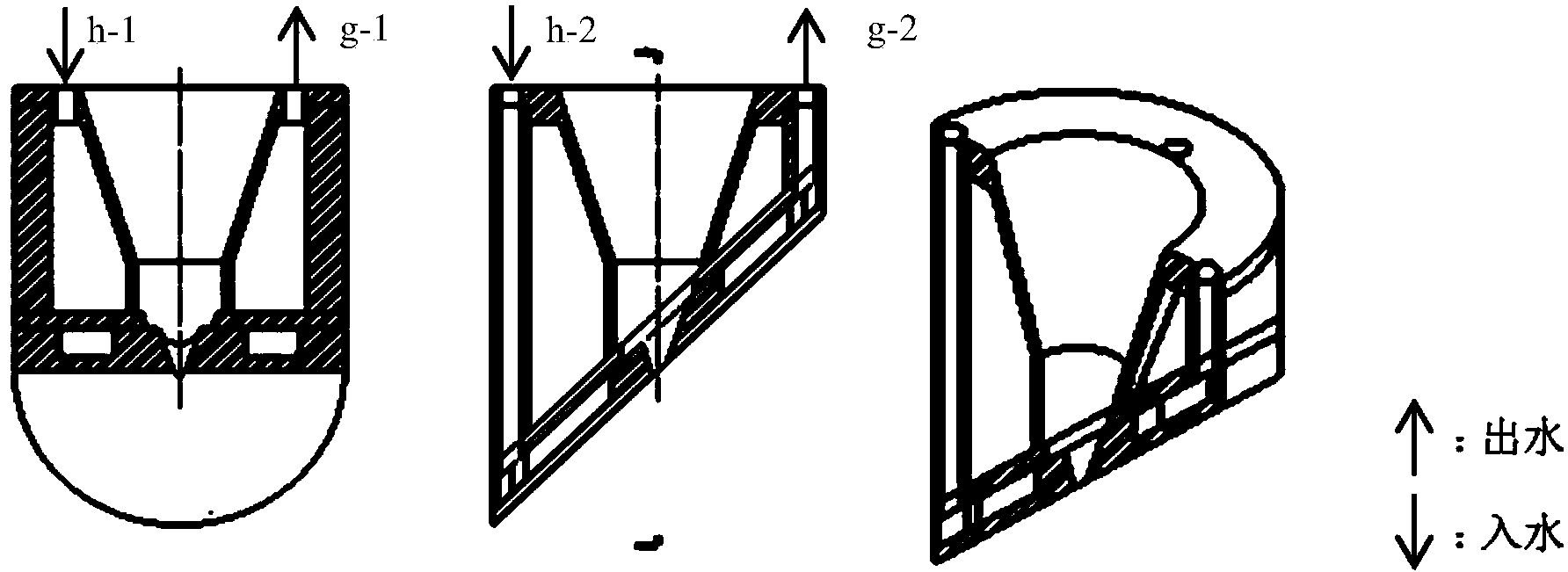

[0056] The optical part includes: He-Ne laser a, pinhole filter b, beam expanding lens group c, thermal field diaphragm assembly d, beam reducing collimating lens group r, and Hartmann wavefront sensor f. The light output from the laser a passes through the pinhole filter b to form a divergent beam, and after passing through the beam expansion lens group c, it is converted into a beam of converging light and forms a real focus, where the central through hole of the thermal field diaphragm d is installed on the real focus Location. The laser beam enters the Hartmann wavefront sensor f through the internal light passage of the thermal field diaphragm d and the beam reduction collimator lens group e, and obtains the real-time wavefront aberration RMS value. The above-mentioned embodiment realizes the simulation of the process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com